TESLA PROJECT BIG COIL

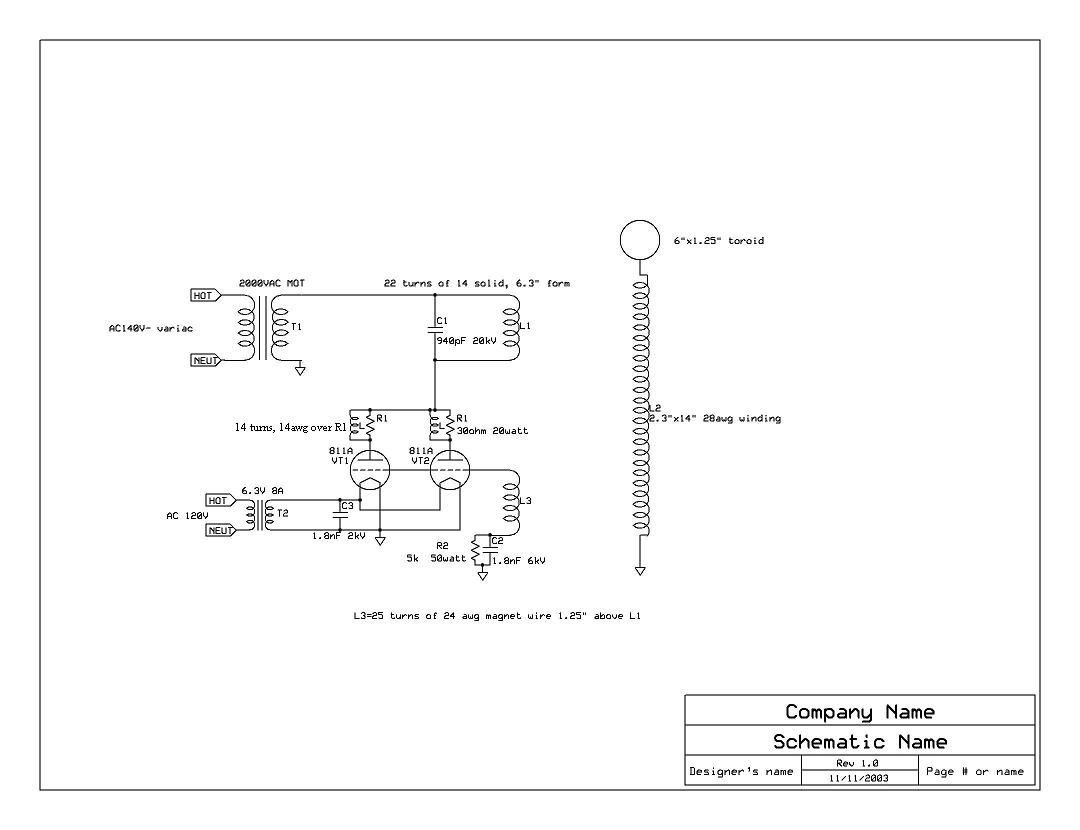

This section details the construction and testing of a medium to large class Tesla coil. A new, larger coil has been redesigned and constructed for maximum efficiency, featuring a secondary coil over 6 inches in diameter and capable of operating at approximately 1,440 watts. The Tesla coil project primarily targets the scientific and Tesla coil enthusiast community, with intended applications including lightning demonstrations and entertainment. Previous coils were of lower power and experimental in nature. The new coil is a 1.5 kVA unit powered by two 12 kV, 60 mA neon sign transformers (NSTs) and features a 6-inch secondary built from scratch. The secondary form consists of layered acrylic fabric sheets reinforced with styrofoam to create a 6-inch diameter cylinder, laminated with multiple layers of polystyrene resin. Each end is sealed with 1/4 inch plexiglass, and the form is wound with approximately 900 turns of #22 magnet wire. The tank circuit employs a modified RQ spark gap with ten 3" x 3/4" copper pipe electrodes and ten doorknob capacitors in parallel, each rated at 2500 pF at 30 kV, yielding a total capacitance of 0.025 µF. The tank circuit is constructed with 1/4" copper tubing, encased in clear neoprene and heavy metal strips for the capacitors. The primary coil is configured as a 15-degree inverted cone made from 1/4" copper tubing, with approximately 10 turns tapped at the eighth turn. The coil is supported by an 18-inch wooden frame mounted on casters for mobility. Safety features include three safety gaps: two formed by bolts on the doorknob EMMC bank, and one on the supply panel, which incorporates two RF chokes (each with 100 turns of #22 wire on a 1" PVC form) and high-voltage terminals. The panel safety gap creates a spark gap between the earth ground post and the two high-voltage supply inputs. The toroids are interchangeable and consist of two 11" salad bowl halves or an oversized toroid measuring 6" by 18" in diameter. The system is powered by a dedicated power supply that provides high voltage to the terminals and powers the spark gap quench motor. This power supply includes two parallel 12 kV, 60 mA NSTs, each with a 130 µF power factor correction capacitor at its input. A key switch and main power switch with an indicator light control a 10A variac for the NSTs. A voltmeter, connected through a diode and a 12V transformer, displays a range of 0-15 (x1000) volts. Upon activation via the main switch, a buzzer sounds as a high-voltage warning alarm, which can be silenced by an additional switch. The power supply features dual outlets—one for variac output and another for the quench motor—both controlled by a switch. Four high-voltage outputs are located on the rear of the unit, utilizing PVC cap bushings. Two outputs are sourced from one NST, while the other two are from the second NST, with a bus strip paralleling the outputs. High-voltage wiring consists of #14 house wire encased in neoprene tubing, connecting the power supply to the Tesla coil. The power supply is also mounted on wheels for ease of mobility, weighing approximately 75 pounds. This Tesla coil system is capable of generating arcs exceeding four feet under optimal conditions. Images of the completed coil and its operation are available, although the previous Tesla coils, including the dual unit and original power supply, were dismantled to source components for this build. Key insights gained from this project include the critical importance of toroids and top-loads in determining the characteristics of Tesla coil sparks. Future modifications may involve utilizing the 4x24 secondary from the disassembled older coil and implementing a well-quenched spark gap, along with refining the copper tube connections to minimize sharp turns and ensure proper soldering. Enhanced spark gap quenching has also been addressed by adding an additional fan to improve cooling.This area shows the construction and testing of a medium to large class Tesla coil. In this section, the previous coils were dismantled and a new larger coil, with a secondary over 6 inches, was redesigned and constructed for maximum efficiency at a power if about 1, 440 watts. The tesla coil project is aimed mainly at the scientific and Tesla coil er community. I intend to use my Tesla coil for lightning demonstrations and entertainment. The Tesla coils so far on this page were of low power and experimental in nature. This section shows a larger and more efficient coil built from scratch and within stricter adherance to the electrical rules involved in Tesla coiling. The new coil is a 1. 5 KVA coil running off a bank of two 12KV, 60 mA NST`s and sports a 6-inch secondary made from scratch!

The secondary form for this coil is made of layered acrylic fabric sheets stiffened with styrofoam to form a 6-inch diameter cylinder and laminated with many layers of polystyrene resin (fiberglass clear boat resin). Each end is sealed and capped with 1/4 inch plexiglass and the form is close-wound with about 900 turns of #22 magnet wire.

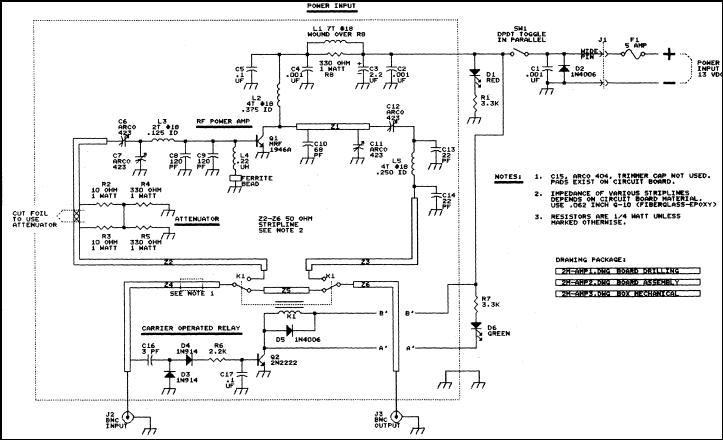

The tank circuit for this coil is a modified RQ spark gap with 10 3" x 3/4" copper pipe electrodes and 10 doorknob capacitors in parallel (each is 2500 pF at 30KV) yeilding 0. 025 uF. The entire tank circuit is wired with 1/4" copper tubing encased in clear neoprene and heavy metal strip for the caps.

The primary is a 15 degree inverted cone of 1/4" copper tubing with 1/4" spacing (about 10 turns tapped at 8). The support for the coil is a wooden frame about 18 inches high on casters for easy movement. There are three safety gaps, two formed by bolts on the doorknob EMMC bank, and one on the "supply panel" where two RF chokes (each 100 turns #22 wire on 1" PVC form) and HV terminals are.

The panel safety gap forms a spark gap between the earth (RF) ground post and the two HV supply inputs. The toroids are easily interchangeable atop the secondary and are the two 11" salad bowl halves, or oversized (6" by 18" diameter) toroid.

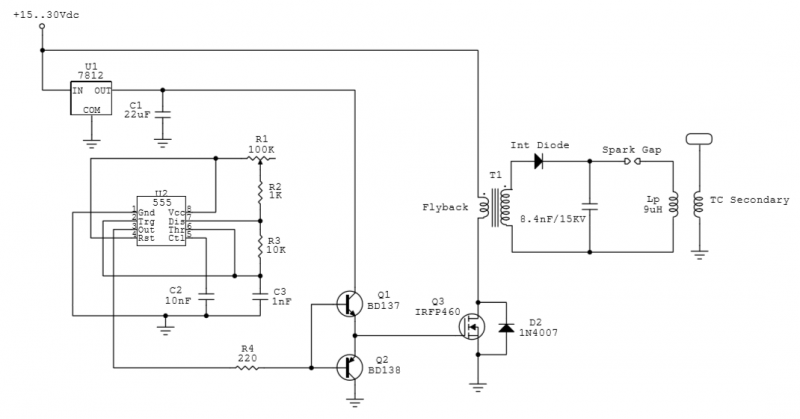

The system is supplied by a separate power supply which supplies the two HV terminals as well as spark-gap quench motor power. This unit contains two 12 KV 60 mA NST`s in parallel with 130 uF PFC capacitor in parallel with each NST input.

There is key switch and main power switch with indicator light which feeds a 10A variac for the NST`s. A voltmeter is fed by a diode and 12V transformer showing 0-15 (x1000) volts. When powered up via the main switch, a buzzer sounds (which also can be silenced by a switch) as a HV warning alarm.

There is also a dual outlet, one for the variac output and the other for the quench motor, also controlled by a switch. There are four HV outputs in the back of this unit on PVC cap "bushings". Two are from one NST, the other two are from the other. A "bus strip" parallels the two NST`s at these output terminals. The HV wires are #14 house wire encased in neoprene tubing, and connect the PSU with the Tesla coil unit.

The PSU also is on wheels for easy moving as it weighs about 75 pounds. This makes this Tesla coil system a 1440 Watt (1. 5 kVA) medium power Tesla coil capeable of generating 4 foot plus arcs under the right conditions! Most pictures of this project are of the completed coil and setup / spark pictures. The only down side is that the older Tesla coils, including the dual unit and original PSU, were dismantled for the parts to build this version. Lessons learned - Toroids and top-loads are VERY important for Tesla coil spark types! Further modifications to this version include using the 4x24 secondary (these are easily changed) from the dismantled old coil, using a well quenched spark gap.

Also modified the copper tube type connections to reduce any "sharp" turns and solder them where necessary. Spark gap quenching is also very important, and an additional fan was added to improve que 🔗 External reference

The secondary form for this coil is made of layered acrylic fabric sheets stiffened with styrofoam to form a 6-inch diameter cylinder and laminated with many layers of polystyrene resin (fiberglass clear boat resin). Each end is sealed and capped with 1/4 inch plexiglass and the form is close-wound with about 900 turns of #22 magnet wire.

The tank circuit for this coil is a modified RQ spark gap with 10 3" x 3/4" copper pipe electrodes and 10 doorknob capacitors in parallel (each is 2500 pF at 30KV) yeilding 0. 025 uF. The entire tank circuit is wired with 1/4" copper tubing encased in clear neoprene and heavy metal strip for the caps.

The primary is a 15 degree inverted cone of 1/4" copper tubing with 1/4" spacing (about 10 turns tapped at 8). The support for the coil is a wooden frame about 18 inches high on casters for easy movement. There are three safety gaps, two formed by bolts on the doorknob EMMC bank, and one on the "supply panel" where two RF chokes (each 100 turns #22 wire on 1" PVC form) and HV terminals are.

The panel safety gap forms a spark gap between the earth (RF) ground post and the two HV supply inputs. The toroids are easily interchangeable atop the secondary and are the two 11" salad bowl halves, or oversized (6" by 18" diameter) toroid.

The system is supplied by a separate power supply which supplies the two HV terminals as well as spark-gap quench motor power. This unit contains two 12 KV 60 mA NST`s in parallel with 130 uF PFC capacitor in parallel with each NST input.

There is key switch and main power switch with indicator light which feeds a 10A variac for the NST`s. A voltmeter is fed by a diode and 12V transformer showing 0-15 (x1000) volts. When powered up via the main switch, a buzzer sounds (which also can be silenced by a switch) as a HV warning alarm.

There is also a dual outlet, one for the variac output and the other for the quench motor, also controlled by a switch. There are four HV outputs in the back of this unit on PVC cap "bushings". Two are from one NST, the other two are from the other. A "bus strip" parallels the two NST`s at these output terminals. The HV wires are #14 house wire encased in neoprene tubing, and connect the PSU with the Tesla coil unit.

The PSU also is on wheels for easy moving as it weighs about 75 pounds. This makes this Tesla coil system a 1440 Watt (1. 5 kVA) medium power Tesla coil capeable of generating 4 foot plus arcs under the right conditions! Most pictures of this project are of the completed coil and setup / spark pictures. The only down side is that the older Tesla coils, including the dual unit and original PSU, were dismantled for the parts to build this version. Lessons learned - Toroids and top-loads are VERY important for Tesla coil spark types! Further modifications to this version include using the 4x24 secondary (these are easily changed) from the dismantled old coil, using a well quenched spark gap.

Also modified the copper tube type connections to reduce any "sharp" turns and solder them where necessary. Spark gap quenching is also very important, and an additional fan was added to improve que 🔗 External reference