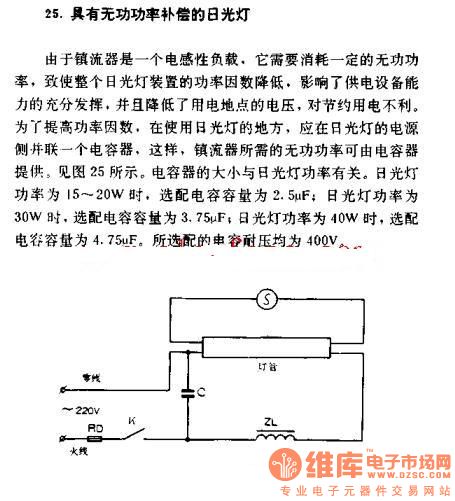

The fluorescent with reactive power compensation circuit diagram

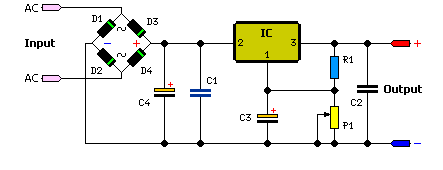

The fluorescent lamp with reactive power compensation operates with a ballast that acts as an inductive load. This inductive load requires reactive power, which leads to a decrease in the power factor of the fluorescent lamp. A lower power factor adversely impacts the performance of fully powered devices, reduces the voltage at power stations, and is detrimental to energy conservation. To enhance the power factor, a capacitor should be connected in parallel with the fluorescent lamp power supply. This configuration allows the capacitor to supply the reactive power required by the ballast. The appropriate capacitor size is correlated with the power rating of the fluorescent lamp. For a fluorescent lamp rated at 15 to 20W, a matching capacitance of 2.5 µF is recommended; for a 30W lamp, an optional capacitance of 3.75 µF is suitable; and for a 40W lamp, a capacitance of 4.75 µF is advised. The optional capacitor voltage rating should be 400V.

The described circuit configuration addresses the issue of reactive power consumption in fluorescent lamp systems. Fluorescent lamps, typically equipped with electromagnetic ballasts, exhibit inductive characteristics that necessitate reactive power for their operation. This requirement can lead to a reduced power factor, which in turn can cause inefficiencies in electrical systems, potentially leading to increased energy costs and reduced performance of connected devices.

Incorporating a capacitor in parallel with the fluorescent lamp's power supply effectively compensates for the inductive reactance introduced by the ballast. By providing the necessary reactive power, the capacitor improves the overall power factor of the system, thereby enhancing the efficiency of energy usage. The selection of capacitor size is critical and must be matched to the power rating of the fluorescent lamp to achieve optimal performance.

For instance, a 15 to 20W fluorescent lamp would require a capacitor with a capacitance of 2.5 µF, while a 30W lamp would necessitate a 3.75 µF capacitor, and a 40W lamp would require 4.75 µF. It is also essential to ensure that the voltage rating of the capacitor is at least 400V to withstand the operating conditions without failure.

This configuration not only improves the power factor but also contributes to a more stable voltage supply from power stations, thus supporting energy conservation efforts and enhancing the reliability of the electrical system. Proper implementation of this reactive power compensation method is crucial for optimizing the performance of fluorescent lighting systems in both residential and commercial applications.The fluorescent with reactive power compensation As ballast is an inductive load. It needs to consume some reactive power, causing the power factor of fluorescent lamp decreases. It affects the ability of full-powered devices, and reduces the voltage of power stations, and it`s harmful to saving electricity. In order to improve power factor, where the using of fluorescent lamps, fluorescent lamp power supply side should be parallel connected a capacitor, so that the ballast`s reactive power can be provided by capacitor. Figure 25 shows. The size of capacitor and fluorescent power is related. Fluorescent power is 15 ~ 20W, matching capacitance is 2. 5 F; fluorescent power is 30w, the optional capacitance is 3. 75 F; fluorescent power is 40w, the optional capacitance is 4. 75 F. The optional capacitor voltage are 400V. 🔗 External reference

The described circuit configuration addresses the issue of reactive power consumption in fluorescent lamp systems. Fluorescent lamps, typically equipped with electromagnetic ballasts, exhibit inductive characteristics that necessitate reactive power for their operation. This requirement can lead to a reduced power factor, which in turn can cause inefficiencies in electrical systems, potentially leading to increased energy costs and reduced performance of connected devices.

Incorporating a capacitor in parallel with the fluorescent lamp's power supply effectively compensates for the inductive reactance introduced by the ballast. By providing the necessary reactive power, the capacitor improves the overall power factor of the system, thereby enhancing the efficiency of energy usage. The selection of capacitor size is critical and must be matched to the power rating of the fluorescent lamp to achieve optimal performance.

For instance, a 15 to 20W fluorescent lamp would require a capacitor with a capacitance of 2.5 µF, while a 30W lamp would necessitate a 3.75 µF capacitor, and a 40W lamp would require 4.75 µF. It is also essential to ensure that the voltage rating of the capacitor is at least 400V to withstand the operating conditions without failure.

This configuration not only improves the power factor but also contributes to a more stable voltage supply from power stations, thus supporting energy conservation efforts and enhancing the reliability of the electrical system. Proper implementation of this reactive power compensation method is crucial for optimizing the performance of fluorescent lighting systems in both residential and commercial applications.The fluorescent with reactive power compensation As ballast is an inductive load. It needs to consume some reactive power, causing the power factor of fluorescent lamp decreases. It affects the ability of full-powered devices, and reduces the voltage of power stations, and it`s harmful to saving electricity. In order to improve power factor, where the using of fluorescent lamps, fluorescent lamp power supply side should be parallel connected a capacitor, so that the ballast`s reactive power can be provided by capacitor. Figure 25 shows. The size of capacitor and fluorescent power is related. Fluorescent power is 15 ~ 20W, matching capacitance is 2. 5 F; fluorescent power is 30w, the optional capacitance is 3. 75 F; fluorescent power is 40w, the optional capacitance is 4. 75 F. The optional capacitor voltage are 400V. 🔗 External reference