The grain based on PIC18F4580 weighs system design

The grain measurement system evaluates the primary technical indicators of grain quality, including the miscellaneous rate and volume density. This measurement not only determines the grade and price of the grain but also directly influences its processing quality and edibility. The precision of the weighing system should adhere to the GB/T 5498 standard, with a unit weight measurement accuracy of 1 gram. To ensure that the grain's miscellaneous rate and volume density are accurately captured and that the measuring instrument meets national standards, a high-precision weighing system based on a PIC microcontroller has been designed. This system measures the weight of the grain while recognizing the volume density and miscellaneous components, isolating impurities through a separator. It then calculates the miscellaneous rate and unit weight, which are essential parameters for evaluating grain samples quickly.

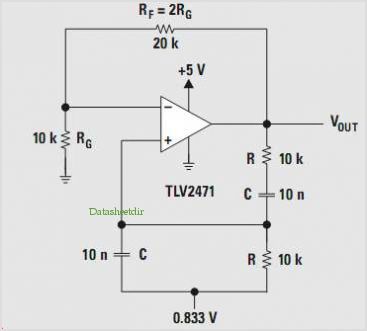

The high-precision weighing system operates as follows: In the grain measurement device, a load sensor positioned beneath the feed cylinder converts the sample's weight into an electrical signal. This electrical signal first passes through a passive low-pass filter to eliminate noise from the wiring, and then it is amplified using an AD7799 instrumentation amplifier. The PIC18F4580 microcontroller serves as the main control unit, managing the reading and writing of registers on the AD converter through an SPI interface to facilitate data sampling. The data is displayed on an LCD, and user input is managed through a keypad, enabling functions such as mutual debugging and data storage. A USART module is employed for data transmission to a host computer.

The system is powered by a low-noise power supply that stabilizes the operational environment, minimizing noise during data sampling. The PIC18F4580 is an 8-bit Flash microcontroller from Microchip Technology, featuring low power consumption and integrated SRAM and EEPROM, with a programming space of 32 KB and a standby current of less than 0.1 mA. The microcontroller can operate with a system clock of up to 32 MHz, simplifying circuit board design. It also includes multiple external resources such as SPI, USART, and timers, which streamline the software command operations by converting them into value assignments for relevant registers, thereby simplifying the design process.

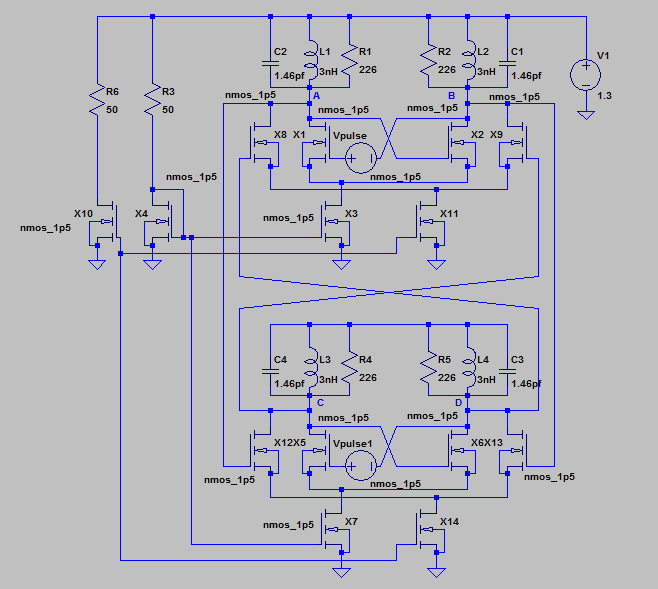

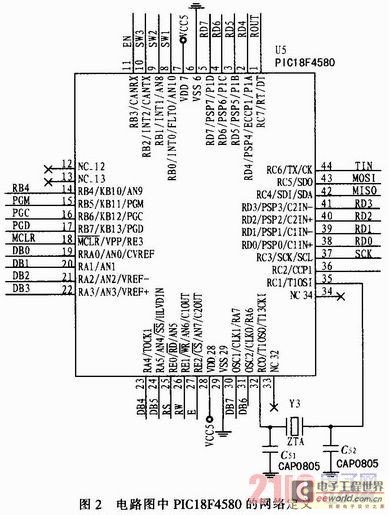

In terms of software debugging and programming, the system requires only four I/O pins for procedure downloading and online debugging, significantly reducing hardware debugging time. The design integrates several modules with the PIC18F4580 as the central control device: an AD module connected via SPI, a USART serial port module, a 12864 LCD module for display, and an interface for procedure downloading and debugging. The pin connection network for the chip is illustrated in the schematic diagram, detailing the interconnections necessary for the operation of the grain measurement system.The grain measures the main technical indicator of grain quality to includes miscellaneous rate and volume density, not only determine grade and price of the grain, but also know direct influence it processes quality and edible quality. <>And stipulate the precision weighed should be up to 0 in 5498 grain of GB/ T, oil examine the mensuration

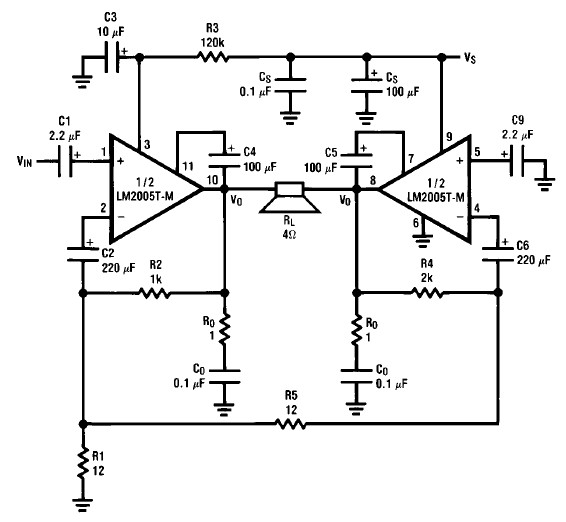

of unit weight. 1 g, in order to make the grain include miscellaneous rate and volume density integral characteristic of measuring instrument and meet requirements for national standard, this text has designed the high precision based on PIC one-chip computer to weigh the system, this system measures the weight of grain in weight and volume density recognizer miscellaneous in magnitude isolated by the impurity separator, and then get including miscellaneous rate and unit weight, etc. and used in the segmental key index parameter of grain of the sample fast. The principle that high precision weighs the system is shown as in Fig. 1, in the grain include miscellaneous rate and volume density meter, the load sensor installed below the feed cylinder changes the sample weight into the electric signal, the electric signal passes a passive low-pass filter with the incoming noise of wire rod of filtration first, and then amplify concurrent implementation AD to change to it by AD7799 instrument amplifier attached.

Regard PIC18F4580 as the top management unit, read and write each register on AD to control AD to sample through SPI interface. The man-machine interface samples the data got by LCD liquid crystal display, the key set realizes the input of the function.

Mutual, debug and data storage that USART module is used for carrying on the data with the upper computer. The low-noise power is used for driving systems simulation part and load sensor, offer the stable work environment in order to reduce the noise that the power brings at the time of systematic sampling.

PIC18F4580 is 8 FLASH little controllers that Microchip Company produces. Slice has low power consumption technology of mW grade at the same time from SRAM and 256bytesEEPROM with 32 K programming space, 1 536 bytes, only consume 0 under the standby mode. Working current of 2 A. Slice can totally substitute the Jingzhen of outside from processing rate with system clock achievable 32 MHz, simplify the circuit board to design.

In addition there is SPI, many kinds of USART, TIMER, etc. has resources outside, changes complicated software command operation into the value assignment to the relevant register, have simplified and designed the process. In view of software debugging and programming, only need to take up 4 I/ O pins and finish the download of procedure and debug online, reduce the time of the cost in the bottom layer hardware is debugged greatly.

In this design, PIC18F4580 has connected module of many stature as the key control device: 1AD of the the strategic hinterland of China SPI interface gathers the module; 2USART serial port module; 312864 liquid crystal module operated by combining the mouth: 4No. 8 of what the procedure is used while controlling expands I/ O mouth; 5The procedure downloads and debug interface.

In the real schematic circuit diagram, the definition of the pin connection network of the chip is shown as in Fig. 2. The grain measures the main technical indicator of grain quality to includes miscellaneous rate and volume density, not only determine grade and price of the grain, but also know direct influence it processes quality and edible quality.

<>And stipulate the precision weighed should be up to 0 in 5498 grain of GB/ T, oil examine the mensuration of unit weight. 1 g, in order to make the grain include miscellaneous rate and volume density integral characteristic of measuring instrument and meet requirements for national standard, this text has designed the high precision based on PIC one-chip computer to weigh the system, this system me

🔗 External reference

The high-precision weighing system operates as follows: In the grain measurement device, a load sensor positioned beneath the feed cylinder converts the sample's weight into an electrical signal. This electrical signal first passes through a passive low-pass filter to eliminate noise from the wiring, and then it is amplified using an AD7799 instrumentation amplifier. The PIC18F4580 microcontroller serves as the main control unit, managing the reading and writing of registers on the AD converter through an SPI interface to facilitate data sampling. The data is displayed on an LCD, and user input is managed through a keypad, enabling functions such as mutual debugging and data storage. A USART module is employed for data transmission to a host computer.

The system is powered by a low-noise power supply that stabilizes the operational environment, minimizing noise during data sampling. The PIC18F4580 is an 8-bit Flash microcontroller from Microchip Technology, featuring low power consumption and integrated SRAM and EEPROM, with a programming space of 32 KB and a standby current of less than 0.1 mA. The microcontroller can operate with a system clock of up to 32 MHz, simplifying circuit board design. It also includes multiple external resources such as SPI, USART, and timers, which streamline the software command operations by converting them into value assignments for relevant registers, thereby simplifying the design process.

In terms of software debugging and programming, the system requires only four I/O pins for procedure downloading and online debugging, significantly reducing hardware debugging time. The design integrates several modules with the PIC18F4580 as the central control device: an AD module connected via SPI, a USART serial port module, a 12864 LCD module for display, and an interface for procedure downloading and debugging. The pin connection network for the chip is illustrated in the schematic diagram, detailing the interconnections necessary for the operation of the grain measurement system.The grain measures the main technical indicator of grain quality to includes miscellaneous rate and volume density, not only determine grade and price of the grain, but also know direct influence it processes quality and edible quality. <>And stipulate the precision weighed should be up to 0 in 5498 grain of GB/ T, oil examine the mensuration

of unit weight. 1 g, in order to make the grain include miscellaneous rate and volume density integral characteristic of measuring instrument and meet requirements for national standard, this text has designed the high precision based on PIC one-chip computer to weigh the system, this system measures the weight of grain in weight and volume density recognizer miscellaneous in magnitude isolated by the impurity separator, and then get including miscellaneous rate and unit weight, etc. and used in the segmental key index parameter of grain of the sample fast. The principle that high precision weighs the system is shown as in Fig. 1, in the grain include miscellaneous rate and volume density meter, the load sensor installed below the feed cylinder changes the sample weight into the electric signal, the electric signal passes a passive low-pass filter with the incoming noise of wire rod of filtration first, and then amplify concurrent implementation AD to change to it by AD7799 instrument amplifier attached.

Regard PIC18F4580 as the top management unit, read and write each register on AD to control AD to sample through SPI interface. The man-machine interface samples the data got by LCD liquid crystal display, the key set realizes the input of the function.

Mutual, debug and data storage that USART module is used for carrying on the data with the upper computer. The low-noise power is used for driving systems simulation part and load sensor, offer the stable work environment in order to reduce the noise that the power brings at the time of systematic sampling.

PIC18F4580 is 8 FLASH little controllers that Microchip Company produces. Slice has low power consumption technology of mW grade at the same time from SRAM and 256bytesEEPROM with 32 K programming space, 1 536 bytes, only consume 0 under the standby mode. Working current of 2 A. Slice can totally substitute the Jingzhen of outside from processing rate with system clock achievable 32 MHz, simplify the circuit board to design.

In addition there is SPI, many kinds of USART, TIMER, etc. has resources outside, changes complicated software command operation into the value assignment to the relevant register, have simplified and designed the process. In view of software debugging and programming, only need to take up 4 I/ O pins and finish the download of procedure and debug online, reduce the time of the cost in the bottom layer hardware is debugged greatly.

In this design, PIC18F4580 has connected module of many stature as the key control device: 1AD of the the strategic hinterland of China SPI interface gathers the module; 2USART serial port module; 312864 liquid crystal module operated by combining the mouth: 4No. 8 of what the procedure is used while controlling expands I/ O mouth; 5The procedure downloads and debug interface.

In the real schematic circuit diagram, the definition of the pin connection network of the chip is shown as in Fig. 2. The grain measures the main technical indicator of grain quality to includes miscellaneous rate and volume density, not only determine grade and price of the grain, but also know direct influence it processes quality and edible quality.

<>And stipulate the precision weighed should be up to 0 in 5498 grain of GB/ T, oil examine the mensuration of unit weight. 1 g, in order to make the grain include miscellaneous rate and volume density integral characteristic of measuring instrument and meet requirements for national standard, this text has designed the high precision based on PIC one-chip computer to weigh the system, this system me

🔗 External reference