The MiniBlok II Push-Pull Amp

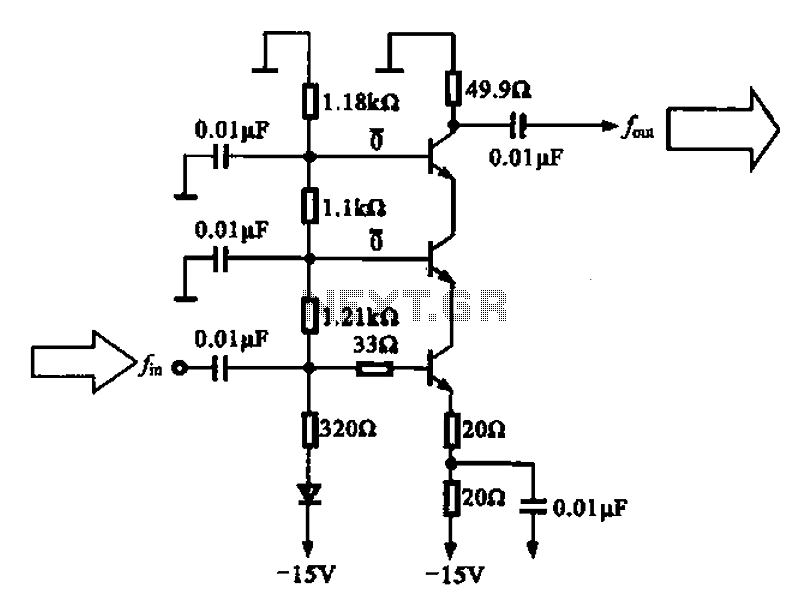

The push-pull MiniBlok II amplifier utilizes the cost-effective 13EM7 "dissimilar dual triode" (or its variants, the 10EM7 or 13EM7/15EA7), maintaining the same operating point as the original single-ended design for a fair comparison between the two topologies. Two of these tubes are necessary for the push-pull configuration. One small triode section serves as the preamplifier, while the two power triode sections form the push-pull output stage, also operating at similar points. An additional small voltage amplifier triode is used to create a phase-inverter for the "paraphase splitter." Three distinct power supplies are required: the first ("A" supply) heats the tube filaments, the second provides high voltage for the plate circuits ("B" supply), and the third supplies negative grid bias for the power amplifier ("C" supply). The incoming 120 VAC power is switched by S1 and directed to a step-down transformer T1. Unlike the transformer in the original MiniBlok, the MiniBlok II employs a 24VAC, 40VA "Class 2" transformer, which is typically used for low-voltage AC in household wiring and is designed for installation in standard circuit boxes. Although more expensive than standard experimenter transformers, it offers higher quality and greater power output for its size. The output from T1 powers the tube heaters, which are connected in series, providing slightly over 12 volts for each filament. This voltage is slightly lower than the tubes' ratings but is sufficient for operation. AC heating is utilized, as it is effective due to the 13EM7's indirectly-heated cathode being resistant to AC hum. Additionally, the 24V AC supply connects to a network of diode D4 and capacitors C5, forming a half-wave rectifier that yields approximately 35 volts DC. This could serve as the grid bias for the output stages, but an extra step is taken to ensure balanced output tubes. The grid bias is partly derived from cathode resistors R15 and R16, with an expected current draw of about 40 mA, resulting in a voltage drop of 13.2 volts across these resistors. Thus, an additional 15 volts of grid bias is necessary to reach the desired operating point. A combination of resistor R14 and zener diode D3 provides this grid bias voltage. This biasing method reduces mismatches in output tube sections; if one tube draws more current, the increased voltage drop across the cathode resistor raises the grid-to-cathode voltage, counteracting the current increase. In the prototype, a 50% difference in plate current between two tubes using fixed-bias was reduced to 10% with this joint cathode-grid biasing scheme, which also minimizes the supply voltage drop compared to a traditional cathode biasing approach. An optional pilot lamp network is included.

The MiniBlok II amplifier circuit employs a push-pull configuration that enhances audio fidelity and efficiency. The 13EM7 tubes are strategically arranged to leverage their dual triode structure, with one triode functioning as a preamplifier and the other two operating in push-pull mode for output amplification. This design choice allows for a balanced output stage, which is crucial for minimizing distortion and improving sound quality.

The power supply architecture consists of three distinct supplies, each serving a specific purpose. The "A" supply provides filament heating, ensuring that the tubes reach their optimal operating temperature. The "B" supply delivers high voltage to the plate circuits, which is essential for the amplification process. The "C" supply offers negative grid bias, which is critical for controlling the operating point of the output tubes.

The choice of a 24VAC, 40VA Class 2 transformer for the MiniBlok II is significant. This transformer is designed for reliability and efficiency, providing sufficient power for the tube heaters while maintaining a compact size. The series connection of the tube heaters ensures that they operate effectively within their rated specifications, despite the slight undervoltage.

The rectification stage, consisting of diode D4 and capacitors C5, is designed to convert the AC supply to DC efficiently. The resulting voltage is used in conjunction with the cathode resistors to establish a balanced biasing scheme that compensates for any current mismatches between the output tubes. This innovative biasing approach not only enhances performance but also reduces the potential for distortion, making the MiniBlok II a robust choice for audio amplification applications.

Overall, the design of the MiniBlok II amplifier reflects a careful consideration of component selection, circuit topology, and operational efficiency, resulting in a high-quality audio amplifier suitable for various applications.As in the original single-ended design, the push-pull MiniBlok II uses the relatively inexpensive 13EM7 "dissimilar dual triode" (or its variants the 10EM7 or 13EM7/15EA7). Using the same tube with essentially the same operating point makes for a more equitable comparison between the single-ended and push-pull topologies.

However, it should be fairly obvious that two of these are required for the push-pull version. As before, one of the small triode sections is used as our preamplifier. The component values are, in fact, exactly the same. The two power triode sections form our push-pull output stage, again with essentially the same operating point. That leaves one small voltage amplifier triode, which will form our phase-inverter for the "paraphase splitter".

As before, there are essentially three separate power supplies required: The first ("A" supply) is to heat the filament of the tubes, the second provides the high voltage for the plate circuits (the "B" supply), and the third provides a portion of the negative grid bias for the power amplifier ("C" supply). Incoming power from the 120 VAC power line is switched by on-off switch S1, and thence applied to step-down transformer T1.

Unlike the replacement-grade transformer used in MiniBlok, however, MiniBlok II uses a 24VAC, 40VA "Class 2" transformer. This kind of transformer is commonly used to provide low-voltage AC in house wiring, and is supplied with a large mounting nut suitable for installing in standard circuit boxes.

While these are more expensive than the usual run of experimenter transformers, they are of higher quality and therefore capable of supplying more power for a given physical size. Although a 24V, 40VA unit is not much larger than the 12. 6 volt at 2 ampere unit used for T1 in MiniBlok, it is capable of nearly twice the output power. As before, the output from T1 supplies the power for the tubes` heaters. The two tubes` heaters are connected in series, resulting in a bit over 12 volts for each filament. (Though this is about a volt lower than the tubes` ratings, it works just fine. ) Again, we don`t bother converting to DC, in this application an AC heater is just fine because 1) we`re not dealing with extremely high gain, and 2) the 13EM7`s indirectly-heated cathode is naturally highly immune to AC hum.

At the same time, this 24 volt AC supply is connected to the network consisting of diode D4 and capacitors C5. This is a simple half-wave rectifier that provides about 35 volts DC at the junction of D4 and C5. This could have been used as our C supply (grid bias) for the output stages, but we`re going to go an extra step to help insure that our two output tubes are balanced.

Part of our grid bias is derived from cathode resistors R15 and R16. Assuming that the tubes will draw about 40 mA in operation, this means that the voltage across R15 and R16 will be (330 * 0. 035)V = 13. 2 volts. This means that we only need about 15 volts of additional grid bias to set the tubes near our desired operating point.

The network consisting of resistor R14 and zener diode D3 provides this grid bias voltage. During operation, mismatches between the two output tube sections will be significantly reduced by this combination biasing method. The reason is that if one of the tubes should draw more current, it will cause a higher voltage drop across the cathode resistor; this in turn increases the grid-to-cathode voltage, tending to buck the increase in current.

In the prototype, there was a 50% difference in plate current between the two tubes I had on hand, using fixed-bias only; this dropped to a mere 10% difference using the joint cathode-grid biasing scheme. At the same time, it only "wastes" half of the supply voltage drop that a straight cathode biasing scheme would require.

An optional pilot lamp network cons 🔗 External reference

The MiniBlok II amplifier circuit employs a push-pull configuration that enhances audio fidelity and efficiency. The 13EM7 tubes are strategically arranged to leverage their dual triode structure, with one triode functioning as a preamplifier and the other two operating in push-pull mode for output amplification. This design choice allows for a balanced output stage, which is crucial for minimizing distortion and improving sound quality.

The power supply architecture consists of three distinct supplies, each serving a specific purpose. The "A" supply provides filament heating, ensuring that the tubes reach their optimal operating temperature. The "B" supply delivers high voltage to the plate circuits, which is essential for the amplification process. The "C" supply offers negative grid bias, which is critical for controlling the operating point of the output tubes.

The choice of a 24VAC, 40VA Class 2 transformer for the MiniBlok II is significant. This transformer is designed for reliability and efficiency, providing sufficient power for the tube heaters while maintaining a compact size. The series connection of the tube heaters ensures that they operate effectively within their rated specifications, despite the slight undervoltage.

The rectification stage, consisting of diode D4 and capacitors C5, is designed to convert the AC supply to DC efficiently. The resulting voltage is used in conjunction with the cathode resistors to establish a balanced biasing scheme that compensates for any current mismatches between the output tubes. This innovative biasing approach not only enhances performance but also reduces the potential for distortion, making the MiniBlok II a robust choice for audio amplification applications.

Overall, the design of the MiniBlok II amplifier reflects a careful consideration of component selection, circuit topology, and operational efficiency, resulting in a high-quality audio amplifier suitable for various applications.As in the original single-ended design, the push-pull MiniBlok II uses the relatively inexpensive 13EM7 "dissimilar dual triode" (or its variants the 10EM7 or 13EM7/15EA7). Using the same tube with essentially the same operating point makes for a more equitable comparison between the single-ended and push-pull topologies.

However, it should be fairly obvious that two of these are required for the push-pull version. As before, one of the small triode sections is used as our preamplifier. The component values are, in fact, exactly the same. The two power triode sections form our push-pull output stage, again with essentially the same operating point. That leaves one small voltage amplifier triode, which will form our phase-inverter for the "paraphase splitter".

As before, there are essentially three separate power supplies required: The first ("A" supply) is to heat the filament of the tubes, the second provides the high voltage for the plate circuits (the "B" supply), and the third provides a portion of the negative grid bias for the power amplifier ("C" supply). Incoming power from the 120 VAC power line is switched by on-off switch S1, and thence applied to step-down transformer T1.

Unlike the replacement-grade transformer used in MiniBlok, however, MiniBlok II uses a 24VAC, 40VA "Class 2" transformer. This kind of transformer is commonly used to provide low-voltage AC in house wiring, and is supplied with a large mounting nut suitable for installing in standard circuit boxes.

While these are more expensive than the usual run of experimenter transformers, they are of higher quality and therefore capable of supplying more power for a given physical size. Although a 24V, 40VA unit is not much larger than the 12. 6 volt at 2 ampere unit used for T1 in MiniBlok, it is capable of nearly twice the output power. As before, the output from T1 supplies the power for the tubes` heaters. The two tubes` heaters are connected in series, resulting in a bit over 12 volts for each filament. (Though this is about a volt lower than the tubes` ratings, it works just fine. ) Again, we don`t bother converting to DC, in this application an AC heater is just fine because 1) we`re not dealing with extremely high gain, and 2) the 13EM7`s indirectly-heated cathode is naturally highly immune to AC hum.

At the same time, this 24 volt AC supply is connected to the network consisting of diode D4 and capacitors C5. This is a simple half-wave rectifier that provides about 35 volts DC at the junction of D4 and C5. This could have been used as our C supply (grid bias) for the output stages, but we`re going to go an extra step to help insure that our two output tubes are balanced.

Part of our grid bias is derived from cathode resistors R15 and R16. Assuming that the tubes will draw about 40 mA in operation, this means that the voltage across R15 and R16 will be (330 * 0. 035)V = 13. 2 volts. This means that we only need about 15 volts of additional grid bias to set the tubes near our desired operating point.

The network consisting of resistor R14 and zener diode D3 provides this grid bias voltage. During operation, mismatches between the two output tube sections will be significantly reduced by this combination biasing method. The reason is that if one of the tubes should draw more current, it will cause a higher voltage drop across the cathode resistor; this in turn increases the grid-to-cathode voltage, tending to buck the increase in current.

In the prototype, there was a 50% difference in plate current between the two tubes I had on hand, using fixed-bias only; this dropped to a mere 10% difference using the joint cathode-grid biasing scheme. At the same time, it only "wastes" half of the supply voltage drop that a straight cathode biasing scheme would require.

An optional pilot lamp network cons 🔗 External reference