Thrifty LED Protector

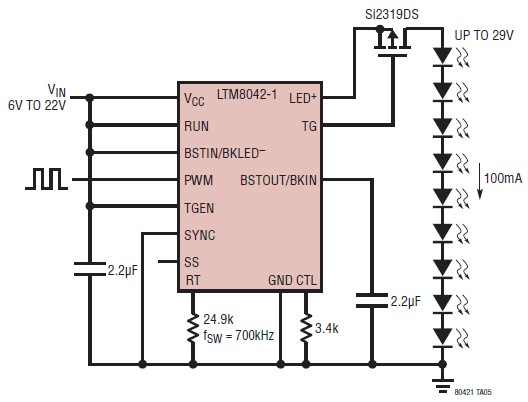

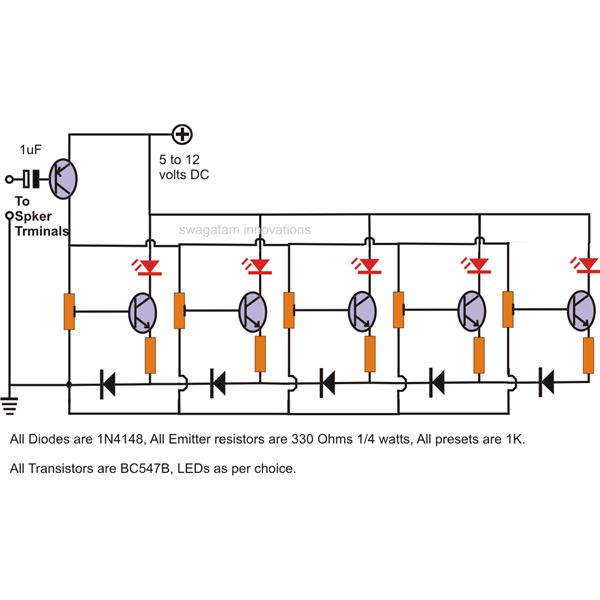

An LED will fail if the current flowing through it is excessively high. This issue can be easily resolved by incorporating a simple resistor in series, which is an effective and low-cost solution. However, as the power supply voltage increases, more power is dissipated in the resistor. For battery-operated devices, it is beneficial to create a power-saving version, which requires additional components. The circuit presented has been intentionally designed with commonly available parts, except for the small coil. Most modern switching power supplies incorporate current monitoring to prevent component failure due to excessive current or power. This is achieved by using resistor R5 to measure the current through the coil, while transistor T2 ensures that the current does not exceed safe levels. The inductor L1 is designed to avoid saturation, which could cause T3 to fail. When the current through R5 reaches approximately 25 mA, T2 conducts, while T1 and T3 block, redirecting the current through LED D1, which lights up. This configuration allows D1 to function as a free-wheeling diode, enhancing efficiency. When the current decreases, T2 blocks, and T3 conducts. Resistor R6 introduces a small amount of hysteresis to maintain the switching frequency around 50 kHz, minimizing losses. The circuit operates with a supply voltage of approximately five volts, depending on the LED's forward voltage, with noticeable efficiency improvements at around 9V. It is compatible with all LED types, including blue and white LEDs that require 3.5V. The coil's output voltage adjusts automatically, with a maximum power supply voltage of 24V. The coil selection is flexible, with values such as 3.9 mH, 6.8 mH, or even 10 mH being suitable, particularly for power supply voltages above 9V. The coil must support at least 25 mA, and physical dimensions should be at least 15 mm in length and 7 mm in diameter. Recent advancements in coil technology have led to the development of smaller SMD coils capable of handling high currents, although they typically do not exceed values of 1 mH.

The described circuit effectively manages LED current through a combination of resistive and inductive components, ensuring safe operation while maximizing efficiency. The use of a series resistor (R5) provides a simple method for current measurement, while transistor T2 acts as a protective switch that prevents excessive current flow. The inductor L1 plays a critical role in energy storage and release, allowing for a smooth current flow to the LED (D1) when T2 is conducting. This arrangement not only protects the LED from overcurrent conditions but also enhances the overall efficiency of the circuit by utilizing D1 as a free-wheeling diode.

The hysteresis introduced by resistor R6 is essential for stabilizing the operation of the circuit, preventing rapid switching that could lead to increased power loss. The circuit is designed to operate effectively across a range of supply voltages, making it versatile for different applications. The adaptability of the coil value allows for customization based on specific requirements, making it suitable for various LED types.

In summary, this circuit design provides a robust solution for driving LEDs safely while optimizing efficiency, making it ideal for use in battery-powered devices and other applications where power conservation is critical. The careful selection of components and their arrangement within the circuit ensures reliable operation and longevity of the LEDs used.An LED is sure to fail if the current through it is too high. You will soon discover this after you have blown a few up. A simple resistor in series suffices to solve the problem and a better solution is almost inconceivable, because in this case you need only one additional cheap component. As the power supply voltage increases, an increasing amo unt of power is lost in the resistor. In particular with battery-powered equipment it is worthwhile to make a power-saving version, which does require a few more parts however. The circuit shown in the figure has deliberately been designed with parts that everyone will have lying around, except perhaps the small coil.

In nearly all modern switching power supplies there is an attempt to monitor the current. It is generally the case that components will fail if the current or power is too high and this is very effectively avoided with this technique. It works like this. Resistor R5 measures the current through the coil and T2 watches` to make sure it doesn`t become too large.

L1 will never go into saturation, which could cause T3 to give up the ghost. As soon as the current through R5 increases to about 25 mA, T2 will conduct, T1 will block and T3 will also block. The current cannot flow through T3 any more and will look for another path, in this case through LED D1, which will now light up.

By placing D1 in this position it acts in fact as a free-wheeling diode, which is good for the efficiency. As soon as the current drops, T2 will block again and T3 will conduct. R6 provides a small amount of hysteresis so that the switching frequency of about 50 kHz does not become unnecessarily high (which would increase the loss).

The circuit works from about five volts, depending on the forward voltage of the LED. From about 9V you will clearly notice the improvement in efficiency. The circuit is suitable for all types of LEDs, including the blue and white ones that need 3. 5 V. The voltage that is generated by the coil will automatically adapt. The maximum power supply voltage is 24 V. A little clarification regarding the choice of coil: the value is not critical, it could just as easily be 3. 9 mH or 6. 8 mH. Even 10 mH can be used, especially if the power supply voltage is greater than 9 V. The coil does need to be suitable for at least 25 mA. You can usually take a guess based on the physical dimensions of the coil. The coil will have to be at least 15 mm long and have a diameter of 7 mm. Incidentally, there have been great advances regarding coils in the least few years. Modern SMD-coils are much smaller and can nevertheless handle high currents. Unfortunately they are not usually available in values over 1 mH. 🔗 External reference

The described circuit effectively manages LED current through a combination of resistive and inductive components, ensuring safe operation while maximizing efficiency. The use of a series resistor (R5) provides a simple method for current measurement, while transistor T2 acts as a protective switch that prevents excessive current flow. The inductor L1 plays a critical role in energy storage and release, allowing for a smooth current flow to the LED (D1) when T2 is conducting. This arrangement not only protects the LED from overcurrent conditions but also enhances the overall efficiency of the circuit by utilizing D1 as a free-wheeling diode.

The hysteresis introduced by resistor R6 is essential for stabilizing the operation of the circuit, preventing rapid switching that could lead to increased power loss. The circuit is designed to operate effectively across a range of supply voltages, making it versatile for different applications. The adaptability of the coil value allows for customization based on specific requirements, making it suitable for various LED types.

In summary, this circuit design provides a robust solution for driving LEDs safely while optimizing efficiency, making it ideal for use in battery-powered devices and other applications where power conservation is critical. The careful selection of components and their arrangement within the circuit ensures reliable operation and longevity of the LEDs used.An LED is sure to fail if the current through it is too high. You will soon discover this after you have blown a few up. A simple resistor in series suffices to solve the problem and a better solution is almost inconceivable, because in this case you need only one additional cheap component. As the power supply voltage increases, an increasing amo unt of power is lost in the resistor. In particular with battery-powered equipment it is worthwhile to make a power-saving version, which does require a few more parts however. The circuit shown in the figure has deliberately been designed with parts that everyone will have lying around, except perhaps the small coil.

In nearly all modern switching power supplies there is an attempt to monitor the current. It is generally the case that components will fail if the current or power is too high and this is very effectively avoided with this technique. It works like this. Resistor R5 measures the current through the coil and T2 watches` to make sure it doesn`t become too large.

L1 will never go into saturation, which could cause T3 to give up the ghost. As soon as the current through R5 increases to about 25 mA, T2 will conduct, T1 will block and T3 will also block. The current cannot flow through T3 any more and will look for another path, in this case through LED D1, which will now light up.

By placing D1 in this position it acts in fact as a free-wheeling diode, which is good for the efficiency. As soon as the current drops, T2 will block again and T3 will conduct. R6 provides a small amount of hysteresis so that the switching frequency of about 50 kHz does not become unnecessarily high (which would increase the loss).

The circuit works from about five volts, depending on the forward voltage of the LED. From about 9V you will clearly notice the improvement in efficiency. The circuit is suitable for all types of LEDs, including the blue and white ones that need 3. 5 V. The voltage that is generated by the coil will automatically adapt. The maximum power supply voltage is 24 V. A little clarification regarding the choice of coil: the value is not critical, it could just as easily be 3. 9 mH or 6. 8 mH. Even 10 mH can be used, especially if the power supply voltage is greater than 9 V. The coil does need to be suitable for at least 25 mA. You can usually take a guess based on the physical dimensions of the coil. The coil will have to be at least 15 mm long and have a diameter of 7 mm. Incidentally, there have been great advances regarding coils in the least few years. Modern SMD-coils are much smaller and can nevertheless handle high currents. Unfortunately they are not usually available in values over 1 mH. 🔗 External reference