Transistor Radio Output Stages

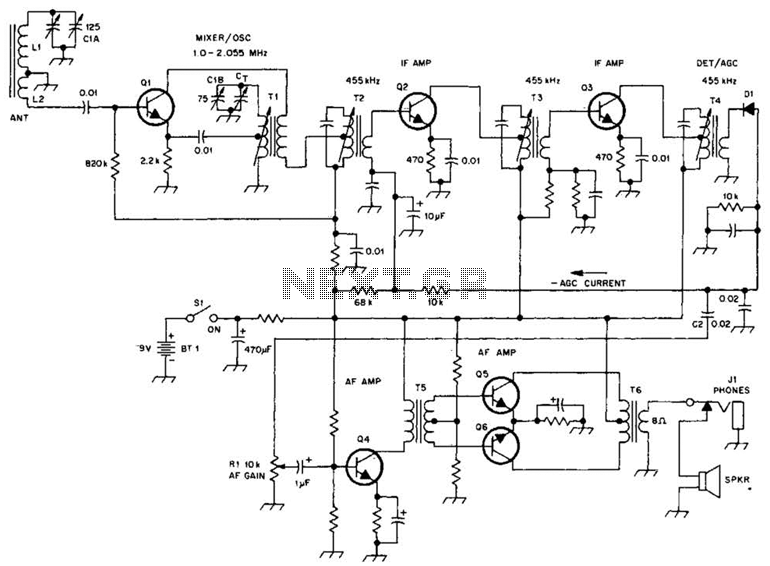

The driver stage operates similarly to the previously described class A output stage, but it functions at a few milliamps, making efficiency less of a concern. The biasing configuration should be recognizable. Some circuits, including the one mentioned, incorporate an additional amplification stage between the volume control and the driver stage. These configurations can better receive weaker signals and potentially deliver higher volume or improved quality for stronger signals. Consequently, the total number of transistors in such designs increases to seven, while those without the extra stage typically utilize six transistors. These configurations represent standard setups, with most early medium wave (MW) and long wave (LW) receivers featuring either six or seven transistors based on the model and original retail price. The current consumption of the class AB output stage fluctuates in accordance with the amplified signal, resulting in variable current draw from the power supply (battery) and subsequent voltage fluctuations. It is crucial to prevent these rapid voltage changes from affecting the driver and preceding stages, as they could induce distortion or instability. In the referenced circuit, a 100 µF capacitor (C7) is positioned directly across the power supply, located near the output stage to smooth out these fluctuations. The supply to the driver stage's biasing and earlier stages is additionally filtered by a 1 k-ohm resistor (R13) and another 100 µF capacitor (C5). Should this capacitor fail, the receiver may produce a disruptive noise known as "motor-boating," reminiscent of an outboard motor. If the 100 µF capacitor across the power supply fails, a similar effect may occur, particularly as the battery begins to deplete. A notable drawback of the two-transformer circuit is the expense and weight associated with the output transformer, which poses a significant issue for higher quality sets, as superior output transformers tend to be larger and more costly than lower quality alternatives. In a printed circuit board (PCB) design, the presence of a large, heavy transformer is undesirable. The driver transformer, which only processes signals rather than power, can be smaller and less burdensome. This circuit illustrates the basic configuration of a single transformer class AB output stage, also referred to as a direct-coupled output stage since the speaker connects directly to the transistors. The two transistors are arranged in series across the power supply and are individually biased. The bases of the transistors are driven by separate windings on the driver transformer. The midpoint of the circuit (between the two transistors) remains at half the supply voltage in the absence of a signal, fluctuating above and below this point with the signal. When two batteries are connected in series, as depicted, the midpoint will also be at half the supply voltage, allowing the other side of the speaker (RL) to connect there. More commonly, a single battery is utilized, with the speaker returning to one side of the supply and an electrolytic capacitor used for DC blocking and AC signal coupling. If this capacitor fails, the output may become weak or distorted. A significant challenge with this circuit is the requirement for a higher impedance speaker, typically ranging from 25 to 75 ohms. These speakers are more complex and costly to manufacture than standard 4 or 8-ohm units, thereby offsetting some of the cost benefits gained from omitting the output transformer. This circuit represents a practical application of this arrangement, based on a Mullard reference circuit, and is indicative of the circuit and component values encountered in many receivers. The bias resistors indicated with an asterisk are specified with a 5% tolerance, while other resistors are rated at 10%. Negative feedback is applied throughout the circuit from the output back to the emitter of the driver transistor via the 2.7 k-ohm resistor at the bottom. The various components are selected to ensure optimal performance and stability of the circuit, addressing the challenges associated with signal amplification and output quality.The driver stage works in the same manner as the class A output stage described previously. However it is only working at a couple of milliamps, so efficiency is not an issue here. The biasing arrangement should be familiar by now. Some sets, including the circuit above, have an extra stage of amplification between the volume control and the drive r stage. Such sets will be able to receive weaker stations better and probably produce higher volume or better quality on stronger signals. This would take the total to seven transistors, whereas sets without this stage have six transistors.

These are the standard line-ups, and most early MW/LW sets will have either six or seven transistors depending on the model and original selling price. Because the class AB output stage current consumption varies with the signal being amplified, the current drawn from the supply (battery) varies in sympathy.

This will cause the supply voltage to fluctuate. We need to prevent these rapid fluctuations from finding their way back to the driver and earlier stages, otherwise they could cause distortion and/or instability. In the circuit above we have a 100uF capacitor (C7) directly across the power supply. This would be mounted close to the output stage and would smooth the fluctuations. The supply to the driver stage biasing and earlier stages in the set is further filtered or decoupled by a 1k-ohm resistor (R13) and another 100uF capacitor (C5).

If this capacitor fails the set will probably make a horrible noise known as "motor-boating" because it resembles the sound of an outboard motor. If the 100uF capacitor directly across the power supply were to fail the same effect would probably occur but only as the battery starts to run down.

The main problem with the two-transformer circuit above is the cost and weight of the output transformer. This is a particular problem with higher quality sets, because good quality output transformers tended to be larger and more expensive than lower quality types.

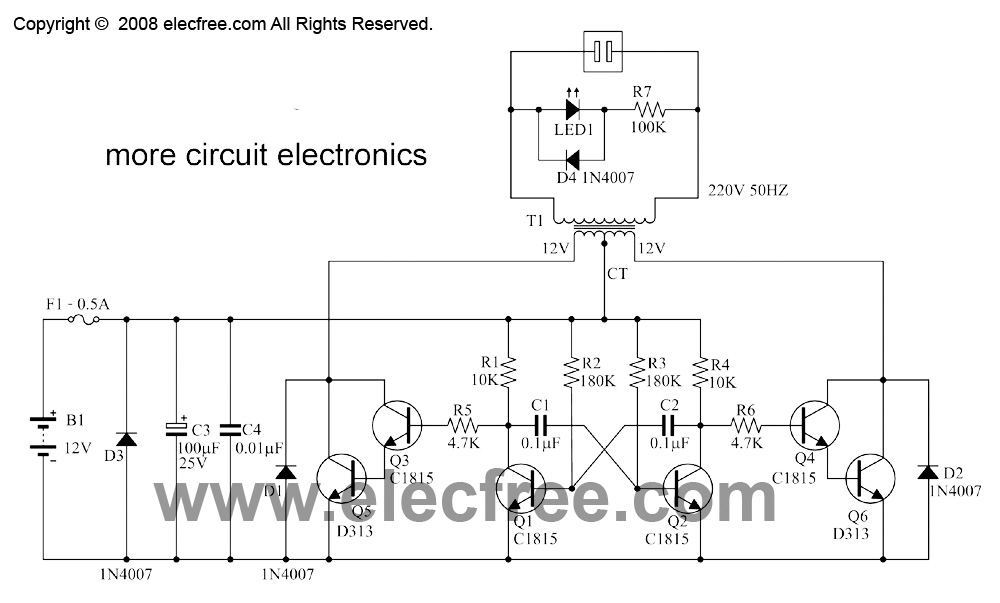

If a set is built on a PCB you really don`t want a big heavy lump of metal mounted on it. The driver transformer only has to deal with signals, not power, so it will be smaller and less of a quality or weight problem. This circuit shows the basic arrangement of a single transformer class AB output stage. It may also be called a direct-coupled output stage since the speaker is directly connected to the transistors.

The two transistors are connected in series across the supply and individually biased. The transistor bases are driven by individual windings on the driver transformer. The central point in the circuit (between the two transistors) will be at half the supply voltage with no signal, and will vary above and below with the signal. If two batteries are used in series, as shown in solid line, the central point between them will also be at half supply voltage, so the other side of the speaker (RL) may be connected to here.

More often however a single battery will be used, so the speaker will be returned to one side of the supply and an electrolytic capacitor will be used for DC blocking and AC signal coupling (shown dotted). If this capacitor fails the output will become weak and/or distorted. The main problem with this circuit is the need for a higher impedance speaker - typically between 25 and 75 ohms.

These are more difficult and expensive to produce than standard 4 or 8 ohm units, which negates some of the cost saving from eliminating the output transformer. This circuit shows a practical implementation of this arrangement. This is a Mullard reference circuit and is typical of the circuit and component values that will be encountered in many sets.

The bias resistors marked * are specified at 5% tolerance, other resistors are 10%. Negative feedback is applied around the whole circuit from the output to the emitter of the driver transistor by the 2. 7k resistor at the bottom. The various 🔗 External reference

These are the standard line-ups, and most early MW/LW sets will have either six or seven transistors depending on the model and original selling price. Because the class AB output stage current consumption varies with the signal being amplified, the current drawn from the supply (battery) varies in sympathy.

This will cause the supply voltage to fluctuate. We need to prevent these rapid fluctuations from finding their way back to the driver and earlier stages, otherwise they could cause distortion and/or instability. In the circuit above we have a 100uF capacitor (C7) directly across the power supply. This would be mounted close to the output stage and would smooth the fluctuations. The supply to the driver stage biasing and earlier stages in the set is further filtered or decoupled by a 1k-ohm resistor (R13) and another 100uF capacitor (C5).

If this capacitor fails the set will probably make a horrible noise known as "motor-boating" because it resembles the sound of an outboard motor. If the 100uF capacitor directly across the power supply were to fail the same effect would probably occur but only as the battery starts to run down.

The main problem with the two-transformer circuit above is the cost and weight of the output transformer. This is a particular problem with higher quality sets, because good quality output transformers tended to be larger and more expensive than lower quality types.

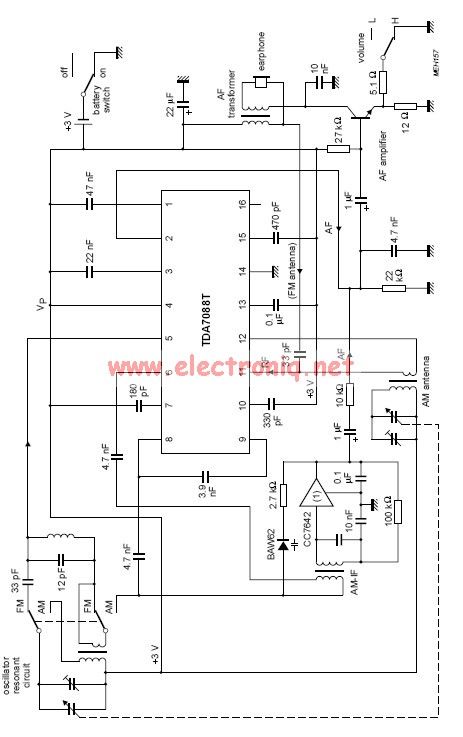

If a set is built on a PCB you really don`t want a big heavy lump of metal mounted on it. The driver transformer only has to deal with signals, not power, so it will be smaller and less of a quality or weight problem. This circuit shows the basic arrangement of a single transformer class AB output stage. It may also be called a direct-coupled output stage since the speaker is directly connected to the transistors.

The two transistors are connected in series across the supply and individually biased. The transistor bases are driven by individual windings on the driver transformer. The central point in the circuit (between the two transistors) will be at half the supply voltage with no signal, and will vary above and below with the signal. If two batteries are used in series, as shown in solid line, the central point between them will also be at half supply voltage, so the other side of the speaker (RL) may be connected to here.

More often however a single battery will be used, so the speaker will be returned to one side of the supply and an electrolytic capacitor will be used for DC blocking and AC signal coupling (shown dotted). If this capacitor fails the output will become weak and/or distorted. The main problem with this circuit is the need for a higher impedance speaker - typically between 25 and 75 ohms.

These are more difficult and expensive to produce than standard 4 or 8 ohm units, which negates some of the cost saving from eliminating the output transformer. This circuit shows a practical implementation of this arrangement. This is a Mullard reference circuit and is typical of the circuit and component values that will be encountered in many sets.

The bias resistors marked * are specified at 5% tolerance, other resistors are 10%. Negative feedback is applied around the whole circuit from the output to the emitter of the driver transistor by the 2. 7k resistor at the bottom. The various 🔗 External reference