Triton Cooling Systems

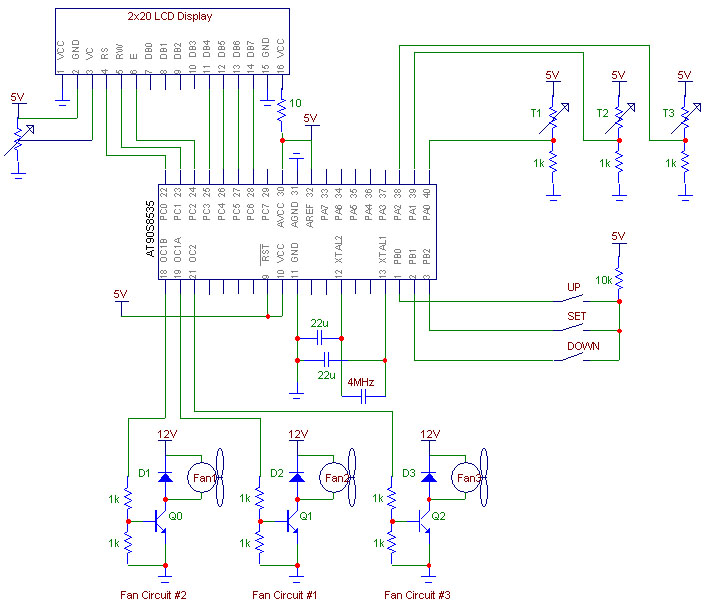

The Lambda II is based on the Atmel 8535 chip, which operates at 4 MHz and contains 8K of RAM. This chip was selected over other brands such as Motorola or PIC due to the simplicity of the circuit used for programming it via a computer, providing an affordable entry point for Atmel products. Although this programming method is effective, a development board named STK-500 was later acquired for the project. This board facilitates programming of any Atmel processor and includes onboard LEDs and switches that can be easily connected to any of the ports, significantly simplifying development and testing procedures. The Atmel AVR STK500 starter kit is specifically designed as a development system for Atmel's AVR flash microcontrollers, offering a quick start for code development on the AVR along with features for prototyping and testing new designs. The STK500 interfaces with AVR Studio, Atmel's Integrated Development Environment (IDE) for code writing and debugging. Three basic external circuits are necessary alongside the Atmel 8535 microcontroller to enable real-world interfacing. The first is an LCD readout for monitoring and adjusting settings, the second is a temperature monitoring system, and the third is a fan control circuit. Most small LCD screens utilize the same controller chip, the Hitachi HD44780, making it relatively straightforward to interface one with the microcontroller. The wiring schematic from the Atmel microcontroller to the LCD readout indicates that Port C of the Atmel 8535 is connected to the 4-bit data bus and the three control lines of the LCD. The fan speed control method employed in this project is Pulse Width Modulation (PWM), which involves toggling the fan's power supply on and off at a fixed frequency to adjust the average DC voltage supplied to the fan. This approach was preferred over linear regulation (varying the input voltage directly) due to PWM's simpler drive circuit, favorable startup characteristics, and minimal heat dissipation in the pass transistor. The setup of this circuit is also detailed in the provided link.

The Lambda II circuit design utilizes the Atmel 8535 microcontroller as its core processing unit, operating at a frequency of 4 MHz with 8K of RAM, which provides sufficient resources for basic control applications. The choice of the Atmel 8535 over competing microcontrollers from manufacturers like Motorola or PIC is primarily attributed to the ease of programming and the cost-effectiveness of the development setup. The integration of the STK-500 development board enhances the design by allowing for straightforward programming and debugging through AVR Studio, which is pivotal for developing and refining the firmware.

The external components connected to the microcontroller include an LCD readout, which serves as a user interface for displaying and modifying settings. The LCD is interfaced using a 4-bit data bus connected to Port C of the Atmel 8535, along with control lines that manage the display operations. This setup leverages the Hitachi HD44780 controller, widely adopted in small LCD screens, ensuring compatibility and ease of integration.

In addition to the LCD, a temperature monitoring system is implemented to gather environmental data, which can be critical for applications requiring temperature regulation. The fan control circuit employs PWM to manage the fan speed efficiently. By rapidly switching the fan's power supply on and off, PWM allows for precise control over the average voltage supplied to the fan, optimizing performance while minimizing heat generation in the control circuitry. This method is particularly advantageous in applications where thermal management is essential, as it provides a balance between effective cooling and energy efficiency.

Overall, the Lambda II project exemplifies a well-structured approach to microcontroller-based design, combining user-friendly interfaces, effective monitoring systems, and efficient control mechanisms to create a versatile and functional electronic system.The Lambda II is based upon the Atmel 8535 chip, which operates at 4 MHz and contains 8K of RAM. This chip was chosen over other brands such as Motorola or Pic, because the circuit used to program it using a computer is very simple to build. This results in an inexpensive way to get started with Atmel products. Although this programming method work s perfectly, a development board called the STK-500 was bought later on in the project. This board allows programming of any Atmel processor, and includes onboard LEDs and switches that can easily be connected to any of the ports. This simplified development and testing procedures greatly. The Atmel AVR STK500 starter kit is specially designed as a development system for Atmel ’s AVR flash microcontrollers.

The STK500 provides a quick start to develop code on the AVR combined with other features to develop prototypes and test new designs. The STK500 interfaces with AVR Studio, Atmel ’s Integrated development Environment (IDE) for code writing and debugging.

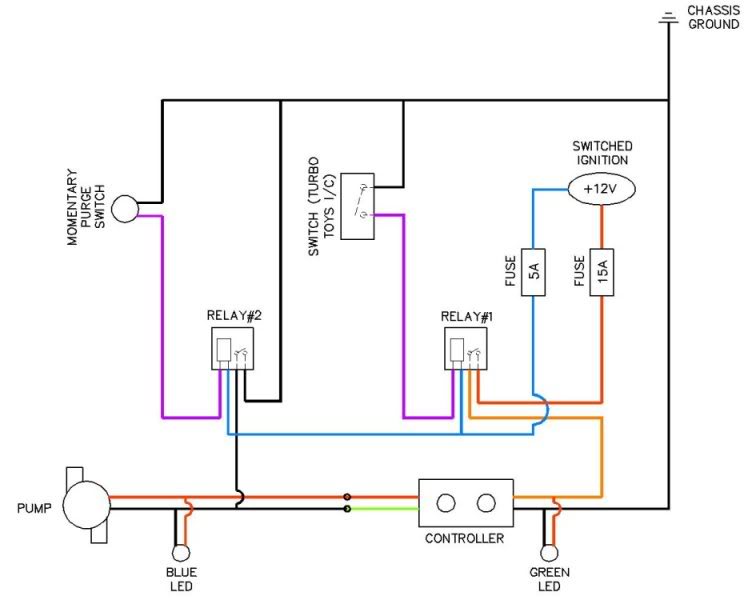

Three basic external circuits were required in addition to the Atmel 8535 microcontroller that allow the processor to be interfaced with the real world. The first is the LCD readout for monitoring and changing settings, the second is the temperature monitoring system, and the third is the fan control circuit.

Because almost all small LCD screens are based on the same controller chip, called the Hitachi HD44780, it is fairly simple to interface one to the microcontroller. The following link shows the wiring schematic from the Atmel microcontroller to the LCD readout. As shown in the figure, Port C of the Atmel 8535 is wired to the 4-bit databus and the three control lines of the LCD.

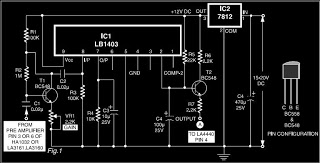

The method used to control fan speeds in this project is called Pulse Width Modulation, or PWM. This involves turning the fan ’s power supply on and off at a fixed frequency to vary the average DC voltage supplied to the fan. This method was chosen over linear regulation (simply varying the input voltage directly), because PWM offers a fairly simple drive circuit, good startup characteristics, and minimal heat dissipation in the pass transistor.

The following link shows how this circuit was set up. 🔗 External reference

The Lambda II circuit design utilizes the Atmel 8535 microcontroller as its core processing unit, operating at a frequency of 4 MHz with 8K of RAM, which provides sufficient resources for basic control applications. The choice of the Atmel 8535 over competing microcontrollers from manufacturers like Motorola or PIC is primarily attributed to the ease of programming and the cost-effectiveness of the development setup. The integration of the STK-500 development board enhances the design by allowing for straightforward programming and debugging through AVR Studio, which is pivotal for developing and refining the firmware.

The external components connected to the microcontroller include an LCD readout, which serves as a user interface for displaying and modifying settings. The LCD is interfaced using a 4-bit data bus connected to Port C of the Atmel 8535, along with control lines that manage the display operations. This setup leverages the Hitachi HD44780 controller, widely adopted in small LCD screens, ensuring compatibility and ease of integration.

In addition to the LCD, a temperature monitoring system is implemented to gather environmental data, which can be critical for applications requiring temperature regulation. The fan control circuit employs PWM to manage the fan speed efficiently. By rapidly switching the fan's power supply on and off, PWM allows for precise control over the average voltage supplied to the fan, optimizing performance while minimizing heat generation in the control circuitry. This method is particularly advantageous in applications where thermal management is essential, as it provides a balance between effective cooling and energy efficiency.

Overall, the Lambda II project exemplifies a well-structured approach to microcontroller-based design, combining user-friendly interfaces, effective monitoring systems, and efficient control mechanisms to create a versatile and functional electronic system.The Lambda II is based upon the Atmel 8535 chip, which operates at 4 MHz and contains 8K of RAM. This chip was chosen over other brands such as Motorola or Pic, because the circuit used to program it using a computer is very simple to build. This results in an inexpensive way to get started with Atmel products. Although this programming method work s perfectly, a development board called the STK-500 was bought later on in the project. This board allows programming of any Atmel processor, and includes onboard LEDs and switches that can easily be connected to any of the ports. This simplified development and testing procedures greatly. The Atmel AVR STK500 starter kit is specially designed as a development system for Atmel ’s AVR flash microcontrollers.

The STK500 provides a quick start to develop code on the AVR combined with other features to develop prototypes and test new designs. The STK500 interfaces with AVR Studio, Atmel ’s Integrated development Environment (IDE) for code writing and debugging.

Three basic external circuits were required in addition to the Atmel 8535 microcontroller that allow the processor to be interfaced with the real world. The first is the LCD readout for monitoring and changing settings, the second is the temperature monitoring system, and the third is the fan control circuit.

Because almost all small LCD screens are based on the same controller chip, called the Hitachi HD44780, it is fairly simple to interface one to the microcontroller. The following link shows the wiring schematic from the Atmel microcontroller to the LCD readout. As shown in the figure, Port C of the Atmel 8535 is wired to the 4-bit databus and the three control lines of the LCD.

The method used to control fan speeds in this project is called Pulse Width Modulation, or PWM. This involves turning the fan ’s power supply on and off at a fixed frequency to vary the average DC voltage supplied to the fan. This method was chosen over linear regulation (simply varying the input voltage directly), because PWM offers a fairly simple drive circuit, good startup characteristics, and minimal heat dissipation in the pass transistor.

The following link shows how this circuit was set up. 🔗 External reference