Turntable Photography Equipment

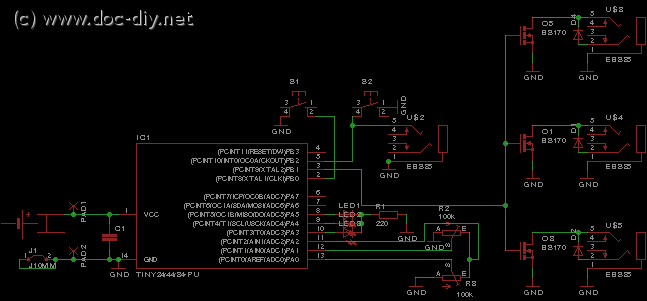

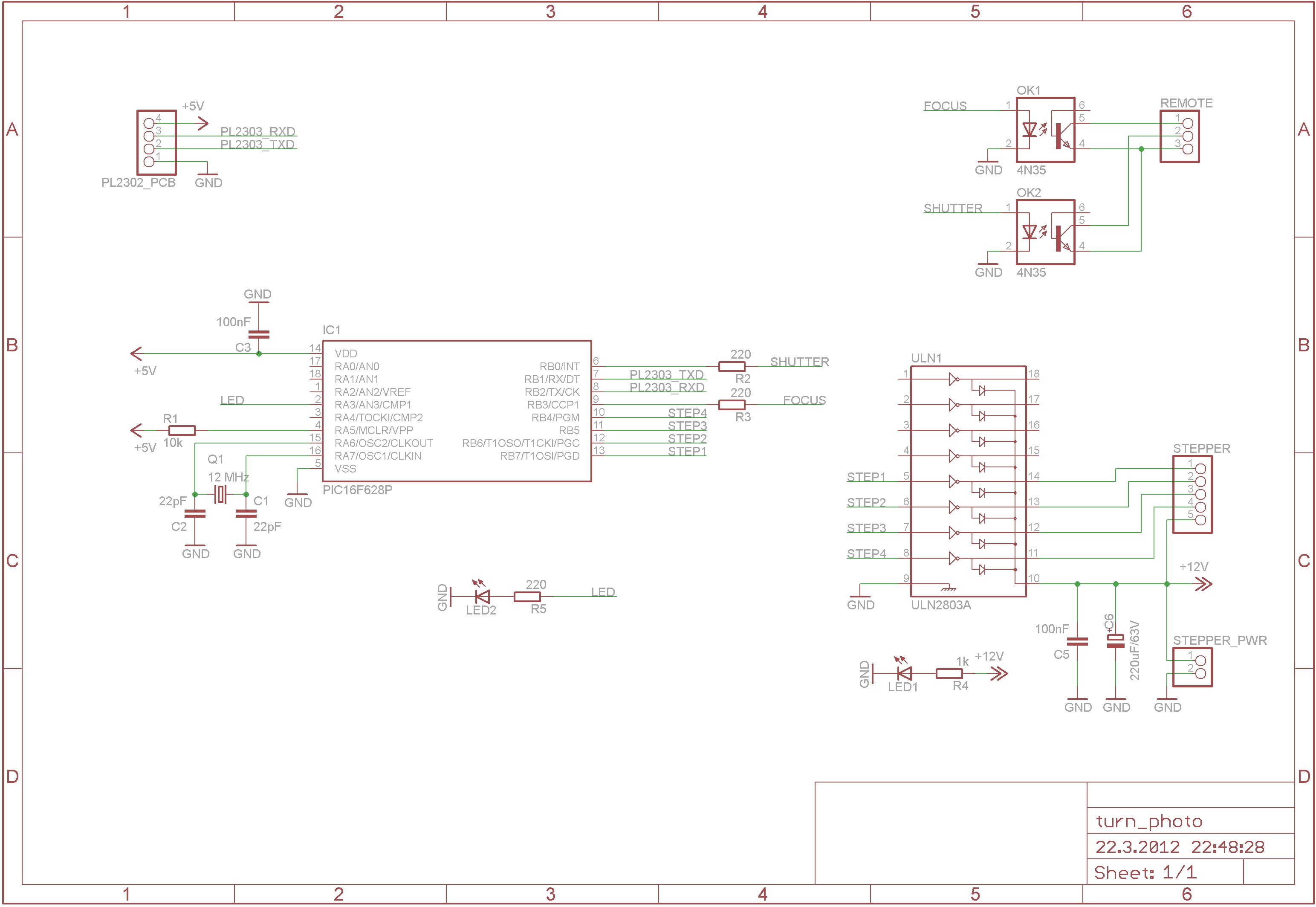

The device captures 360-degree photos, which are essentially animations made from multiple images of a product taken from different angles. It requires a controllable device that can take pictures at even intervals. As depicted in the accompanying image, a device named "Turn Photo" manages the digital camera's focus and shutter, while the device itself is operated through a PC application developed in Delphi 7.

The device primarily consists of a PIC16F628A microcontroller, a USB-to-Serial PL2303 converter IC, a ULN2803A IC transistor array, two opto-couplers, and a stepper motor. The electronics are powered via a USB port, specifically from a PL2303 PCB Module, while the motor is independently powered by a 12V source. Two iterations of this device were constructed. The first utilized a stepper motor sourced from an old 5.25" floppy drive (TEAC 14769070-90), which is a unipolar motor with four coils, providing a resolution of 1.8 degrees per step, resulting in 200 steps per complete revolution. When employing a half-stepping method, this resolution increases to 400 steps per revolution. However, this initial design faced issues due to the absence of gears between the motor and the rotating plate (a circular plexiglass sheet that holds the product), leading to a direct-drive configuration that caused significant vibrations at low speeds. Despite attempts to rectify this through motor driver parameter adjustments and dampers, this direct-drive approach was ultimately abandoned.

The second version incorporated a stepper motor (M35ST-7P) from an old HP scanner, which, like the first, is a unipolar motor with four coils but offers a lower resolution of 7.5 degrees per step, equating to 48 steps per revolution. The advantage of this motor is the inclusion of two gears, resulting in a 1:25 gear ratio that effectively reduces the step size to 0.3 degrees per step (360/48/25). This gearing also allows for increased operational speed, thus eliminating the vibration issues encountered in the first design. The final "drive" gear permits up to 1200 steps, or 2400 with half-stepping, per revolution. A 15.5 cm diameter circular plexiglass plate is affixed to the final gear to hold the product being photographed.

The PIC16F628A microcontroller is tasked with receiving and executing commands from the PC application, controlling both the stepper motor and the camera. The firmware is developed in HI-TECH C and is available for download. Camera operation is facilitated through two 4N35 NPN opto-couplers connected to a 3.5mm female stereo jack, compatible with various cameras. A custom cable was created for a Nikon D700 camera using its remote. The PIC microcontroller receives commands via the USB-to-Serial converter IC, processes the commands, and sends responses back to the PC application. The application, developed in Delphi 7, features a user-friendly interface that allows for parameter adjustments. Currently, the application is available only in Bosnian/Croatian/Serbian, with potential for translation into English upon request. The user can specify the desired number of photos (typically 30-40 for smooth animation), and the application calculates the necessary steps to initiate the process.Take photos in 360 degrees. That kind of photo is actually an animation that consists of several photos of the same product but from different angles. It means that we need a device that can be controllable and that could take pictures on even intervals.

As wecan see from the picture above, a device called "Turn Photo" controls the digital camera (focus and shutter) and the device itself is controlled by a PC application written in Delphi 7. Roughly, the device consists of PIC16F628A microcontroller, USB<->Serial PL2303 converter IC, ULN2803A IC transistor array, 2 opto-couplers and one stepper motor. Electronics are powered from USB port, actually from a PL2303 PCB Module, and motor is powered by independent 12V power source.

Two versions of this device were built. The first one was with stepper motor from an old 5. 25" floppy drive TEAC 14769070-90. That is a unipolar motor with 4 coils inside, and it has a resolution of 1. 8 degrees per step which makes 200 steps in total per one complete revolution. When we drive it with half-stepping method, it doubles to 400 steps per revolution. A problem with this realization was that I didn`t use gears between the motor and the rotating plate (a circular plexiglass sheet that holds/rotates the product) - it was a direct-drive. A thing to note here is that we need to rotate objects with the smallest speed possible to avoid them dancing all over the plate.

So, with a direct-drive and slow motor speed it produced massive vibrations. When motor speeds up - vibrations disappear, but we don`t want it speeding around. After testing and trying to fix the problem by changing stepper motor driver parameters and using dampers I decided to abandon this direct-drive design. Second version of mechanics (the winning combination) is done by using a stepper motor M35ST-7P from an old HP scanner which was also unipolar with 4 coils but with a much smaller resolution of just 7.

5 degrees per step. It means that the motor makes just 48 steps per one revolution. The good thing is that two gears came with this motor and the steps were prescaled by 25 (1:25 gear ratio) which means we now have 360/48/25 = 0. 3 degrees per step. Another good thing here is that we can drive it faster because the speed also reduces by 25 x. This solves the vibrations problem totally and now we also have a maximum of 1200 steps or even 2400 with half-stepping per one revolution of final "drive" gear.

A 15. 5cm diameter circular plexiglass plate is fitted to the final "driving" gear which holds the photographed product. Here cou can see a video of CNC machine drilling the plexiglass circle (warning: very bad video quality).

The PIC16F628A has a job to receive and respond to commands that arrive from the PC application, to control the stepper motor and also to control the camera (focus and shutter). Firmware is written in HI-TECH C language and is also available for download. Camera is controlled with two 4N35 NPN opto-couplers and they are connected to 3. 5mm female stereo jack that accepts a cable for virtually any camera. My friend has a Nikon D700 camera so I made a cable for it from the Nikon`s "remote". PIC microcontroller receives commands from the PC application over USB<->Serial converter IC, completes the requested command and answers back to the PC application.

PIC supports these commands: Application is written in Delphi 7 and has a very simple environment where all parameters can be adjusted. Please note that application is currently only in Bosnian/Croatian/Serbian language, so if anyone is interested, I could translate it to English.

Source-code is available for download on request. After entering the number of required photos (usually 30-40 is enough for a smooth animation), the application will calculate how many steps it needs to make and the process can start. A 🔗 External reference

The device primarily consists of a PIC16F628A microcontroller, a USB-to-Serial PL2303 converter IC, a ULN2803A IC transistor array, two opto-couplers, and a stepper motor. The electronics are powered via a USB port, specifically from a PL2303 PCB Module, while the motor is independently powered by a 12V source. Two iterations of this device were constructed. The first utilized a stepper motor sourced from an old 5.25" floppy drive (TEAC 14769070-90), which is a unipolar motor with four coils, providing a resolution of 1.8 degrees per step, resulting in 200 steps per complete revolution. When employing a half-stepping method, this resolution increases to 400 steps per revolution. However, this initial design faced issues due to the absence of gears between the motor and the rotating plate (a circular plexiglass sheet that holds the product), leading to a direct-drive configuration that caused significant vibrations at low speeds. Despite attempts to rectify this through motor driver parameter adjustments and dampers, this direct-drive approach was ultimately abandoned.

The second version incorporated a stepper motor (M35ST-7P) from an old HP scanner, which, like the first, is a unipolar motor with four coils but offers a lower resolution of 7.5 degrees per step, equating to 48 steps per revolution. The advantage of this motor is the inclusion of two gears, resulting in a 1:25 gear ratio that effectively reduces the step size to 0.3 degrees per step (360/48/25). This gearing also allows for increased operational speed, thus eliminating the vibration issues encountered in the first design. The final "drive" gear permits up to 1200 steps, or 2400 with half-stepping, per revolution. A 15.5 cm diameter circular plexiglass plate is affixed to the final gear to hold the product being photographed.

The PIC16F628A microcontroller is tasked with receiving and executing commands from the PC application, controlling both the stepper motor and the camera. The firmware is developed in HI-TECH C and is available for download. Camera operation is facilitated through two 4N35 NPN opto-couplers connected to a 3.5mm female stereo jack, compatible with various cameras. A custom cable was created for a Nikon D700 camera using its remote. The PIC microcontroller receives commands via the USB-to-Serial converter IC, processes the commands, and sends responses back to the PC application. The application, developed in Delphi 7, features a user-friendly interface that allows for parameter adjustments. Currently, the application is available only in Bosnian/Croatian/Serbian, with potential for translation into English upon request. The user can specify the desired number of photos (typically 30-40 for smooth animation), and the application calculates the necessary steps to initiate the process.Take photos in 360 degrees. That kind of photo is actually an animation that consists of several photos of the same product but from different angles. It means that we need a device that can be controllable and that could take pictures on even intervals.

As wecan see from the picture above, a device called "Turn Photo" controls the digital camera (focus and shutter) and the device itself is controlled by a PC application written in Delphi 7. Roughly, the device consists of PIC16F628A microcontroller, USB<->Serial PL2303 converter IC, ULN2803A IC transistor array, 2 opto-couplers and one stepper motor. Electronics are powered from USB port, actually from a PL2303 PCB Module, and motor is powered by independent 12V power source.

Two versions of this device were built. The first one was with stepper motor from an old 5. 25" floppy drive TEAC 14769070-90. That is a unipolar motor with 4 coils inside, and it has a resolution of 1. 8 degrees per step which makes 200 steps in total per one complete revolution. When we drive it with half-stepping method, it doubles to 400 steps per revolution. A problem with this realization was that I didn`t use gears between the motor and the rotating plate (a circular plexiglass sheet that holds/rotates the product) - it was a direct-drive. A thing to note here is that we need to rotate objects with the smallest speed possible to avoid them dancing all over the plate.

So, with a direct-drive and slow motor speed it produced massive vibrations. When motor speeds up - vibrations disappear, but we don`t want it speeding around. After testing and trying to fix the problem by changing stepper motor driver parameters and using dampers I decided to abandon this direct-drive design. Second version of mechanics (the winning combination) is done by using a stepper motor M35ST-7P from an old HP scanner which was also unipolar with 4 coils but with a much smaller resolution of just 7.

5 degrees per step. It means that the motor makes just 48 steps per one revolution. The good thing is that two gears came with this motor and the steps were prescaled by 25 (1:25 gear ratio) which means we now have 360/48/25 = 0. 3 degrees per step. Another good thing here is that we can drive it faster because the speed also reduces by 25 x. This solves the vibrations problem totally and now we also have a maximum of 1200 steps or even 2400 with half-stepping per one revolution of final "drive" gear.

A 15. 5cm diameter circular plexiglass plate is fitted to the final "driving" gear which holds the photographed product. Here cou can see a video of CNC machine drilling the plexiglass circle (warning: very bad video quality).

The PIC16F628A has a job to receive and respond to commands that arrive from the PC application, to control the stepper motor and also to control the camera (focus and shutter). Firmware is written in HI-TECH C language and is also available for download. Camera is controlled with two 4N35 NPN opto-couplers and they are connected to 3. 5mm female stereo jack that accepts a cable for virtually any camera. My friend has a Nikon D700 camera so I made a cable for it from the Nikon`s "remote". PIC microcontroller receives commands from the PC application over USB<->Serial converter IC, completes the requested command and answers back to the PC application.

PIC supports these commands: Application is written in Delphi 7 and has a very simple environment where all parameters can be adjusted. Please note that application is currently only in Bosnian/Croatian/Serbian language, so if anyone is interested, I could translate it to English.

Source-code is available for download on request. After entering the number of required photos (usually 30-40 is enough for a smooth animation), the application will calculate how many steps it needs to make and the process can start. A 🔗 External reference