ultra capacitor technology powers electronic circuits

As the market seeks lighter, more compact wireless and portable devices with innovative features packed into increasingly constrained spaces, there is a concurrent pursuit for the next power supply innovation—a powerful, compact, long-lasting, economical, and safe battery. Although advancements are being made, current battery technology often compromises desired space and weight specifications while failing to adequately meet peak power requirements. Ultracapacitors, also known as supercapacitors, present an alternative source that promises to bypass the battery dilemma and enhance efficiency from existing power sources. Despite high costs and manufacturability challenges, this electric double-layer capacitor (EDLC), or pseudo capacitor, possesses significant growth potential as it addresses essential market and societal demands: it is environmentally friendly, aids in energy conservation, and improves the performance and portability of consumer devices. Ultracapacitors are also free from typical battery issues, such as limited cycle life, cold intolerance, and critical charging rates. They are being developed as alternatives to pulse batteries, and to be a viable option, ultracapacitors must demonstrate at least one order of magnitude greater power and significantly longer shelf and cycle life than batteries. Although ultracapacitors have a much lower energy density than batteries, this low-energy density is often the determining factor for their feasibility in high-power applications. Conventional electrolytic capacitors, available for decades, serve as energy-storage devices comparable to containers that gradually fill with electrical energy and then release it in sudden bursts. Recently introduced ultracapacitors are high-energy versions of conventional capacitors, capable of holding hundreds of times more energy per unit volume or mass by utilizing advanced materials and high-tech microscopic manufacturing processes. When fully charged, these robust devices provide instant power in a compact and affordable package. The emergence of low-cost, compact ultracapacitors, distinguished by exceptionally high surface area, excellent conductivity, and superior chemical and physical stability, signals a new era of practical application. The equivalent circuit for conventional capacitors can also be applied to ultracapacitors. The circuit schematic represents the first-order model for an ultracapacitor, consisting of four ideal circuit elements: capacitance C, series resistor Rs, parallel resistor Rp, and series inductor L. Rs, known as the equivalent series resistance (ESR), contributes to energy loss during capacitor charging and discharging. Rp simulates energy loss due to self-discharge, often referred to as leakage current resistance. The inductor L arises primarily from the capacitor's physical construction and is usually small; however, it cannot be disregarded in many applications, especially those operating at high frequencies or undergoing hard switching. Typically, resistor Rp is significantly higher than Rs, allowing it to be neglected in high-power applications. In such cases, the impedance of the circuit model is given by Z = R + i(2πfL - 1/2πfC), where L is the inductance in Henries. The impedance is purely resistive when 2πfL - 1/2πfC = 0, or f = 1/2π(LC)½, identifying this frequency as the resonance frequency of the capacitor. Thus, the circuit's impedance is simply the resistance at self-resonance. However, ultracapacitors exhibit non-ideal behavior primarily due to the porous materials used to form the electrodes, which cause the resistance and capacitance to be distributed in a manner that affects performance.

Ultracapacitors are particularly suited for applications requiring rapid charge and discharge cycles, such as in regenerative braking systems in electric vehicles or as backup power sources in renewable energy systems. Their ability to deliver high power instantaneously makes them ideal for applications where quick bursts of energy are necessary, such as in power tools or consumer electronics that demand high peak currents. The development of ultracapacitors continues to focus on enhancing their energy density while maintaining their advantageous properties of high power density and long cycle life. The integration of advanced materials and innovative manufacturing techniques is crucial for overcoming current limitations and expanding their applicability across various sectors, including automotive, aerospace, and consumer electronics. The exploration of hybrid systems that combine ultracapacitors with traditional batteries may also yield significant improvements in overall system performance, allowing for optimized energy management and enhanced device longevity.As the market strives for lighter, more compact wireless and portable devices with more ingenious features crammed into an ever-tighter space, a related quest ensues for the next power supply innovation ” a powerful, compact, long-lasting, economical and safe battery. Although progressing toward this end, current battery technology often comprom ises the desired space and weight specifications without properly satisfying peak power requirements. Ultracapacitors, also known as supercapacitors, offer an alternative source that promises to circumvent the battery scramble and extract greater efficiency from existing power sources.

Because of high price and manufacturability issues, this electric double layer capacitor (EDLC), also known as a pseudo capacitor, isn`t popular among engineers. However, it offers boundless growth potential because it responds to key market and societal needs: It`s environmentally friendly, helps conserve energy, and enhances the performance and portability of consumer devices.

Ultracapacitors also are free from characteristic battery problems, such as limited cycle life, cold intolerance and critical charging rates. Ultracapacitors are being developed as an alternative to pulse batteries. To be an attractive alternative, ultracapacitors must have at least one order of magnitude higher power and a much longer shelf and cycle life than batteries.

Ultracapacitors have much lower energy density than batteries, and their low-energy density is, in most cases, the factor that determines the feasibility of their use in a particular high-power application. Available for decades, a conventional electrolytic capacitor is an energy-storage device that can be compared to a container that gradually fills with electrical energy and then delivers it when needed in a sudden burst.

Offered just recently, an ultracapacitor is a high-energy version of a conventional capacitor, holding hundreds of times more energy per unit volume or mass than the latter by using state-of-the-art materials and high-tech microscopic manufacturing processes. When fully charged, these robust devices deliver instant power in an affordable, compact package. Long considered an enigma because of price, the advent of inexpensive, compact ultracapacitors, characterized by an exceptionally high surface area, excellent conductivity, and superior chemical and physical stability, herald a new era of practical usage.

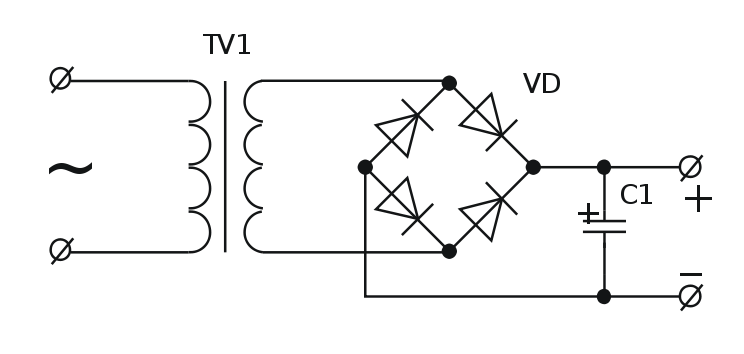

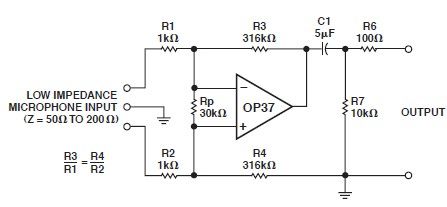

The equivalent circuit used for conventional capacitors can also be applied to ultracapacitors. The circuit schematic in Fig. 2 represents the first-order model for an ultracapacitor. It`s comprised of four ideal circuit elements: a capacitance C, a series resistor Rs, a parallel resistor Rp, and a series inductor L. Rs is called the equivalent series resistance (ESR) and contributes to energy loss during capacitor charging and discharging.

Rp simulates energy loss due to capacitor self-discharge, and is often referred to as the leakage current resistance. Inductor L results primarily from the physical construction of the capacitor and is usually small. However, in many applications, it can`t be neglected ” particularly those operating at high frequencies or subjected to hard switching.

Resistor Rp is always much higher than Rs in practical capacitors. Thus, it often can be neglected, particularly in high-power applications. In that case, the impedance of the Fig. 2 circuit model is: Z = R + i (2pfL-1/2pfC), where L is the inductance in [Henrys]. The impedance is purely resistive when 2pfL-1/2pfC = 0, or f = 1/2 p(LC) ½. This particular frequency is referred to as the resonance frequency of the capacitor. Thus, the impedance of circuit is simply the resistance at self-resonance. However, ultracapacitors exhibit non-ideal behavior, which result primarily from the porous material used to form the electrodes that cause the resistance and capacitance to be distributed such that the 🔗 External reference

Ultracapacitors are particularly suited for applications requiring rapid charge and discharge cycles, such as in regenerative braking systems in electric vehicles or as backup power sources in renewable energy systems. Their ability to deliver high power instantaneously makes them ideal for applications where quick bursts of energy are necessary, such as in power tools or consumer electronics that demand high peak currents. The development of ultracapacitors continues to focus on enhancing their energy density while maintaining their advantageous properties of high power density and long cycle life. The integration of advanced materials and innovative manufacturing techniques is crucial for overcoming current limitations and expanding their applicability across various sectors, including automotive, aerospace, and consumer electronics. The exploration of hybrid systems that combine ultracapacitors with traditional batteries may also yield significant improvements in overall system performance, allowing for optimized energy management and enhanced device longevity.As the market strives for lighter, more compact wireless and portable devices with more ingenious features crammed into an ever-tighter space, a related quest ensues for the next power supply innovation ” a powerful, compact, long-lasting, economical and safe battery. Although progressing toward this end, current battery technology often comprom ises the desired space and weight specifications without properly satisfying peak power requirements. Ultracapacitors, also known as supercapacitors, offer an alternative source that promises to circumvent the battery scramble and extract greater efficiency from existing power sources.

Because of high price and manufacturability issues, this electric double layer capacitor (EDLC), also known as a pseudo capacitor, isn`t popular among engineers. However, it offers boundless growth potential because it responds to key market and societal needs: It`s environmentally friendly, helps conserve energy, and enhances the performance and portability of consumer devices.

Ultracapacitors also are free from characteristic battery problems, such as limited cycle life, cold intolerance and critical charging rates. Ultracapacitors are being developed as an alternative to pulse batteries. To be an attractive alternative, ultracapacitors must have at least one order of magnitude higher power and a much longer shelf and cycle life than batteries.

Ultracapacitors have much lower energy density than batteries, and their low-energy density is, in most cases, the factor that determines the feasibility of their use in a particular high-power application. Available for decades, a conventional electrolytic capacitor is an energy-storage device that can be compared to a container that gradually fills with electrical energy and then delivers it when needed in a sudden burst.

Offered just recently, an ultracapacitor is a high-energy version of a conventional capacitor, holding hundreds of times more energy per unit volume or mass than the latter by using state-of-the-art materials and high-tech microscopic manufacturing processes. When fully charged, these robust devices deliver instant power in an affordable, compact package. Long considered an enigma because of price, the advent of inexpensive, compact ultracapacitors, characterized by an exceptionally high surface area, excellent conductivity, and superior chemical and physical stability, herald a new era of practical usage.

The equivalent circuit used for conventional capacitors can also be applied to ultracapacitors. The circuit schematic in Fig. 2 represents the first-order model for an ultracapacitor. It`s comprised of four ideal circuit elements: a capacitance C, a series resistor Rs, a parallel resistor Rp, and a series inductor L. Rs is called the equivalent series resistance (ESR) and contributes to energy loss during capacitor charging and discharging.

Rp simulates energy loss due to capacitor self-discharge, and is often referred to as the leakage current resistance. Inductor L results primarily from the physical construction of the capacitor and is usually small. However, in many applications, it can`t be neglected ” particularly those operating at high frequencies or subjected to hard switching.

Resistor Rp is always much higher than Rs in practical capacitors. Thus, it often can be neglected, particularly in high-power applications. In that case, the impedance of the Fig. 2 circuit model is: Z = R + i (2pfL-1/2pfC), where L is the inductance in [Henrys]. The impedance is purely resistive when 2pfL-1/2pfC = 0, or f = 1/2 p(LC) ½. This particular frequency is referred to as the resonance frequency of the capacitor. Thus, the impedance of circuit is simply the resistance at self-resonance. However, ultracapacitors exhibit non-ideal behavior, which result primarily from the porous material used to form the electrodes that cause the resistance and capacitance to be distributed such that the 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713