Universal AC Motor Speed Controller Kit

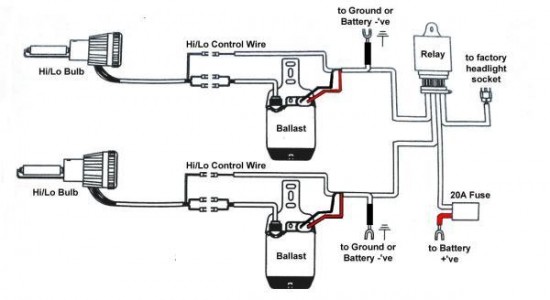

This kit is designed to control the speed of AC motors with carbon brushes, applicable to devices such as drills, saws, and vacuum cleaners. Unlike standard dimmers, this kit performs a phase cut only once per period. The timing of the cut determines the speed, adjustable from 5% to 95%. The kit ensures high torque even at low speeds. RFI is suppressed to minimize noise and interference. The circuit is capable of controlling both low voltage (ranging from 24VAC to 240VAC at 5.5A) AC motors and mains voltage (110VAC or 220VAC) loads. The supply and load circuits are electrically isolated from each other for enhanced safety and reliability. The control circuit is powered by the mains, while the load supply may be sourced from a different AC source. Both voltages must share the same frequency and phase or be in opposite phases.

The AC motor speed control kit is a sophisticated electronic circuit designed to modulate the speed of AC motors equipped with carbon brushes. This versatility allows it to be employed in various applications, including power tools and household appliances. The circuit operates by implementing a phase-cut technique, which differs from conventional dimmer circuits that typically perform multiple cuts within a single AC cycle. By executing a single phase cut per cycle, the kit provides a smoother and more efficient speed control mechanism.

The adjustable speed range, from 5% to 95%, is achieved by altering the timing of the phase cut. This feature is particularly advantageous for applications requiring precise speed control, as it allows the user to optimize motor performance according to specific operational demands. The circuit is engineered to maintain high torque levels even at reduced speeds, ensuring that the motor operates effectively without stalling.

To enhance user experience and maintain operational integrity, the kit incorporates RFI suppression techniques. This minimizes electromagnetic interference, thereby reducing noise that could affect both the motor's performance and other nearby electronic devices.

The kit is designed to handle a wide range of input voltages, accommodating both low voltage AC motors (24VAC to 240VAC at 5.5A) and mains voltage applications (110VAC or 220VAC). The provision of electrical isolation between the supply and load circuits is a critical safety feature, preventing potential hazards associated with electrical faults.

Powering the control circuit directly from the mains ensures reliability, while the option to source the load supply from an alternative AC source offers flexibility in installation. It is essential that both the control and load supplies operate at the same frequency and phase, or are configured to be in opposite phases, to ensure optimal performance and prevent operational conflicts. This comprehensive design makes the AC motor speed control kit a reliable solution for various motor control applications.This kit was designed to control the speed of AC motors with carbon brushes, anything from drills to saws to vacuum cleaners. Unlike other circuits such as normal dimmers the kit performs a phase cut only once per period. The moment of cutting determines the speed, which can be adjusted from 5% to 95%. The kit provides high torque even at low spee ds. RFI is suppressed to eliminate noise and interference. The circuit controls both low voltage (from 24VAC to 240VAC at 5. 5A) AC motors and mains voltage (110VAC or 220VAC) loads. The supply and load circuits are electrically isolated from each other for safety and reliability. The control circuit is powered by the mains, but the load supply may be derived from a different AC source. Both voltages should be the same frequency and the same phase or opposite phase. 🔗 External reference

The AC motor speed control kit is a sophisticated electronic circuit designed to modulate the speed of AC motors equipped with carbon brushes. This versatility allows it to be employed in various applications, including power tools and household appliances. The circuit operates by implementing a phase-cut technique, which differs from conventional dimmer circuits that typically perform multiple cuts within a single AC cycle. By executing a single phase cut per cycle, the kit provides a smoother and more efficient speed control mechanism.

The adjustable speed range, from 5% to 95%, is achieved by altering the timing of the phase cut. This feature is particularly advantageous for applications requiring precise speed control, as it allows the user to optimize motor performance according to specific operational demands. The circuit is engineered to maintain high torque levels even at reduced speeds, ensuring that the motor operates effectively without stalling.

To enhance user experience and maintain operational integrity, the kit incorporates RFI suppression techniques. This minimizes electromagnetic interference, thereby reducing noise that could affect both the motor's performance and other nearby electronic devices.

The kit is designed to handle a wide range of input voltages, accommodating both low voltage AC motors (24VAC to 240VAC at 5.5A) and mains voltage applications (110VAC or 220VAC). The provision of electrical isolation between the supply and load circuits is a critical safety feature, preventing potential hazards associated with electrical faults.

Powering the control circuit directly from the mains ensures reliability, while the option to source the load supply from an alternative AC source offers flexibility in installation. It is essential that both the control and load supplies operate at the same frequency and phase, or are configured to be in opposite phases, to ensure optimal performance and prevent operational conflicts. This comprehensive design makes the AC motor speed control kit a reliable solution for various motor control applications.This kit was designed to control the speed of AC motors with carbon brushes, anything from drills to saws to vacuum cleaners. Unlike other circuits such as normal dimmers the kit performs a phase cut only once per period. The moment of cutting determines the speed, which can be adjusted from 5% to 95%. The kit provides high torque even at low spee ds. RFI is suppressed to eliminate noise and interference. The circuit controls both low voltage (from 24VAC to 240VAC at 5. 5A) AC motors and mains voltage (110VAC or 220VAC) loads. The supply and load circuits are electrically isolated from each other for safety and reliability. The control circuit is powered by the mains, but the load supply may be derived from a different AC source. Both voltages should be the same frequency and the same phase or opposite phase. 🔗 External reference