Water level controller using 8051

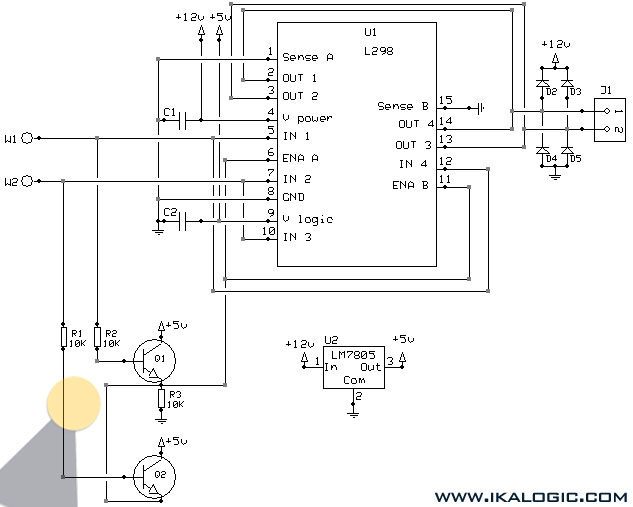

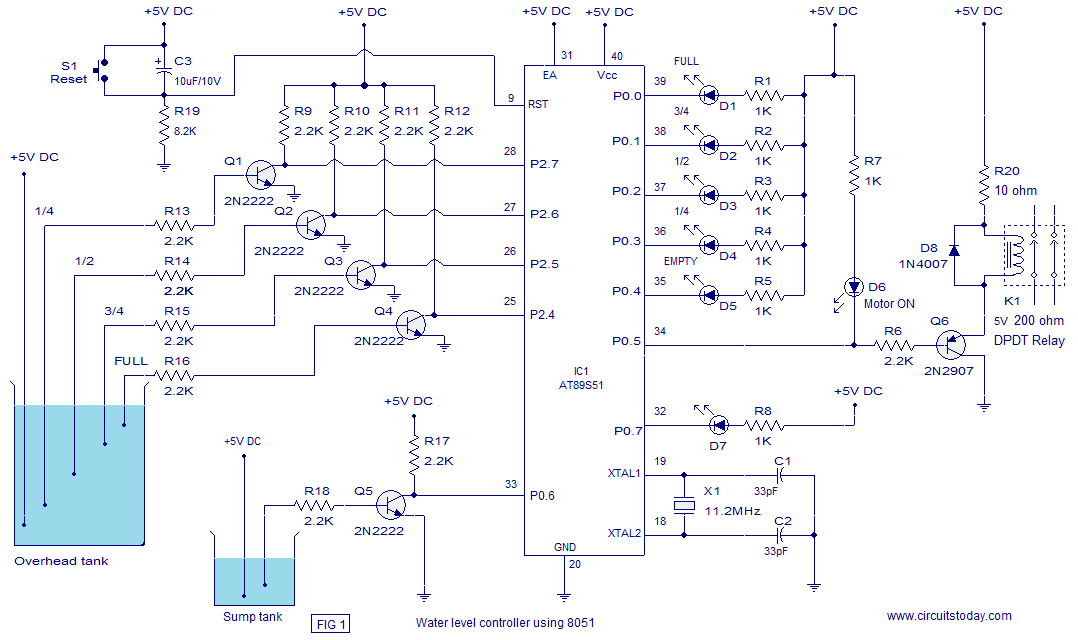

A water level controller based on the 8051 microcontroller is presented in this article. While numerous water level controller projects have been published on this website, this is the first one utilizing a microcontroller. The water level controller monitors the level of the overhead tank and automatically activates the water pump whenever the level falls below a preset limit. The overhead tank's water level is indicated using five LEDs, and the pump is turned off when the tank is filled. The pump will not start if the water level in the sump tank is low, and it is also switched off when the level in the sump tank decreases during a pumping cycle. The circuit diagram of the water level controller is provided below. The level sensor probes for the overhead tank are connected to port 2 of the microcontroller through transistors. The sensor probe arrangement for the overhead tank is illustrated in Fig. 1. A positive voltage supply probe is positioned at the bottom of the tank. Probes for sensing the 1/4, 1/2, 3/4, and FULL levels are placed at equal intervals above the bottom positive probe. The topmost (full level) probe is connected to the base of transistor Q4 through resistor R16. When the water rises to the full level, current flows into the base of transistor Q4, turning it ON and causing its collector voltage to drop. The collector of Q4 is connected to P2.4, and a low voltage at P2.4 indicates that the overhead tank is not FULL. When the water level falls below the full level probe, the base of Q2 becomes open, turning it OFF. Consequently, its collector voltage rises, and a high voltage at P2.4 indicates that the tank is not full. The same principle applies to the other sensor probes (3/4, 1/2, 1/4), and the microcontroller determines the current level by scanning the port pins P2.4, P2.5, P2.6, and P2.7. If all these port pins are high (indicating that all sensor probes are open), the tank is empty. Port pin P0.5 is utilized to control the pump. Whenever it is necessary to start pumping, the controller sets P0.5 low, which activates transistor Q6, in turn activating relay K1 to switch on the pump. Additionally, LED D6 illuminates to indicate that the motor is ON. LED D7 serves as a low sump indicator. When the water level in the sump tank becomes low, the controller sets P0.7 low, causing LED D7 to glow. The circuit diagram of the water level controller is shown in the figure below.

The water level controller circuit employs a microcontroller-based design to efficiently manage the operation of a water pump based on the water levels in both the overhead tank and the sump tank. The system is equipped with multiple sensor probes, each corresponding to specific water levels in the overhead tank, which communicate with the microcontroller through transistor interfaces. This arrangement allows precise monitoring and control of the water levels.

The probes are strategically placed to detect the water levels at 1/4, 1/2, 3/4, and FULL, enabling the microcontroller to ascertain the exact status of the tank. The use of transistors as switches provides electrical isolation and amplifies the signals from the probes, ensuring reliable operation of the control logic. The microcontroller continuously scans the input from the probes, interpreting the voltage levels at the corresponding port pins to determine whether the tank is empty, partially filled, or full.

The control logic includes safety features to prevent the pump from operating under unsafe conditions. If the sump tank level is low, the pump will not activate, preventing potential damage to the pump and ensuring efficient water usage. The incorporation of LEDs provides visual feedback on the system’s status, with specific indicators for pump operation and low sump conditions.

The relay used for controlling the pump provides a robust means of switching the higher power required by the pump, while the microcontroller handles the low power control signals. This design enhances the reliability and functionality of the water level controller, making it suitable for various applications in residential and industrial settings. The circuit diagram serves as a visual representation of the components and their interconnections, aiding in both understanding and implementation of the system.A water level controller based using 8051 is shown in this article. A lot of water level controller projects have been published in this website but the is the first one based on a microcontroller. This water level controller monitors the level of the over head tank and automatically switches on the water pump when ever the level goes below a pres

et limit. The level of the over head tank is indicated using 5 leds and the pump is switched of when the over head tank is filled. The pump is not allowed to start if the water level in the sump tank is low and also the pump is switched off when the level inside the sump tank goes low during a pumping cycle.

The circuit diagram of the water level controller is shown below. The level sensor probes for the overhead tank are interfaced to the port 2 of the microcontroller through transistors. Have a look at the sensor probe arrangement for the overhead tank in Fig1. A positive voltage supply probe goes to the down bottom of the tank. The probes for sensing 1/4, 1/2, 3/4 and FULL levels are placed with equal spacing one by one above the bottom positive probe.

Consider the topmost (full level) probe, its other end is connected to the base of transistor Q4 through resistor R16. Whenever water rises to the full level current flows into the base of transistor Q4 which makes it ON and so its collector voltage goes low.

The collector of Q4 is connected to P2. 4 and a low voltage at P2. 4 means the over head tank is not FULL. When water level goes below the full level probe, the base of Q2 becomes open making it OFF. Now its collector voltage goes high and high at P2. 4 means the tank is not full. The same applies to other sensor probes (3/4, 1/2, 1/4) and the microprocessor understands the current level by scanning the port pins P2. 4, P2. 5, P2. 6 and P2. 7. All these port pin are high (all sensor probes are open) means the tank is empty. Port pin P0. 5 is used to control the pump. When ever it is required start pumping, the controller makes P0. 5 low which makes transistor Q6 ON which in turn activates the relay K1 that switches the pump. Also the LED d6 glows indicating the motor is ON. LED D7 is the low sump indicator. When the water level in the sump tank goes low, the controller makes P0. 7 low which makes LED D7 to glow. The circuit diagram of the water level controller is shown in the figure below. 🔗 External reference

The water level controller circuit employs a microcontroller-based design to efficiently manage the operation of a water pump based on the water levels in both the overhead tank and the sump tank. The system is equipped with multiple sensor probes, each corresponding to specific water levels in the overhead tank, which communicate with the microcontroller through transistor interfaces. This arrangement allows precise monitoring and control of the water levels.

The probes are strategically placed to detect the water levels at 1/4, 1/2, 3/4, and FULL, enabling the microcontroller to ascertain the exact status of the tank. The use of transistors as switches provides electrical isolation and amplifies the signals from the probes, ensuring reliable operation of the control logic. The microcontroller continuously scans the input from the probes, interpreting the voltage levels at the corresponding port pins to determine whether the tank is empty, partially filled, or full.

The control logic includes safety features to prevent the pump from operating under unsafe conditions. If the sump tank level is low, the pump will not activate, preventing potential damage to the pump and ensuring efficient water usage. The incorporation of LEDs provides visual feedback on the system’s status, with specific indicators for pump operation and low sump conditions.

The relay used for controlling the pump provides a robust means of switching the higher power required by the pump, while the microcontroller handles the low power control signals. This design enhances the reliability and functionality of the water level controller, making it suitable for various applications in residential and industrial settings. The circuit diagram serves as a visual representation of the components and their interconnections, aiding in both understanding and implementation of the system.A water level controller based using 8051 is shown in this article. A lot of water level controller projects have been published in this website but the is the first one based on a microcontroller. This water level controller monitors the level of the over head tank and automatically switches on the water pump when ever the level goes below a pres

et limit. The level of the over head tank is indicated using 5 leds and the pump is switched of when the over head tank is filled. The pump is not allowed to start if the water level in the sump tank is low and also the pump is switched off when the level inside the sump tank goes low during a pumping cycle.

The circuit diagram of the water level controller is shown below. The level sensor probes for the overhead tank are interfaced to the port 2 of the microcontroller through transistors. Have a look at the sensor probe arrangement for the overhead tank in Fig1. A positive voltage supply probe goes to the down bottom of the tank. The probes for sensing 1/4, 1/2, 3/4 and FULL levels are placed with equal spacing one by one above the bottom positive probe.

Consider the topmost (full level) probe, its other end is connected to the base of transistor Q4 through resistor R16. Whenever water rises to the full level current flows into the base of transistor Q4 which makes it ON and so its collector voltage goes low.

The collector of Q4 is connected to P2. 4 and a low voltage at P2. 4 means the over head tank is not FULL. When water level goes below the full level probe, the base of Q2 becomes open making it OFF. Now its collector voltage goes high and high at P2. 4 means the tank is not full. The same applies to other sensor probes (3/4, 1/2, 1/4) and the microprocessor understands the current level by scanning the port pins P2. 4, P2. 5, P2. 6 and P2. 7. All these port pin are high (all sensor probes are open) means the tank is empty. Port pin P0. 5 is used to control the pump. When ever it is required start pumping, the controller makes P0. 5 low which makes transistor Q6 ON which in turn activates the relay K1 that switches the pump. Also the LED d6 glows indicating the motor is ON. LED D7 is the low sump indicator. When the water level in the sump tank goes low, the controller makes P0. 7 low which makes LED D7 to glow. The circuit diagram of the water level controller is shown in the figure below. 🔗 External reference