With full power amplifier 01

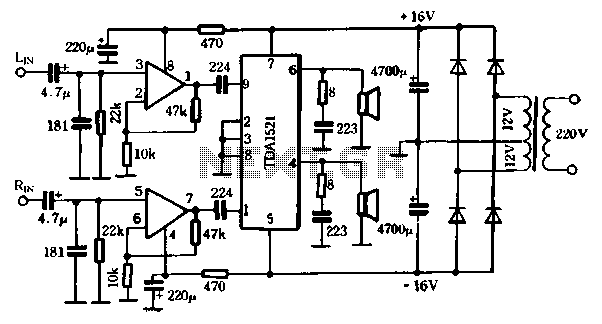

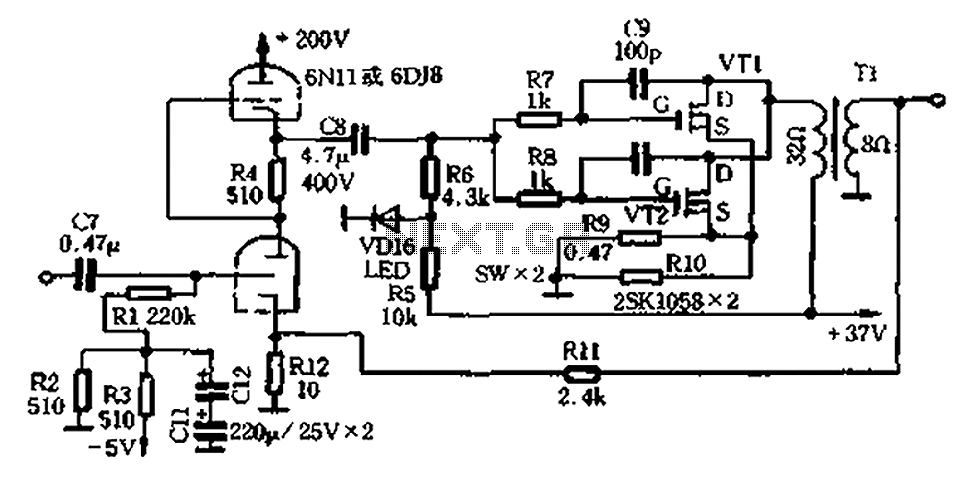

The amplifier circuit illustrated in Figure 2-25 features the following: (1) It utilizes a class 6N11 tube for parallel push-pull amplification, providing high-frequency response and an excellent signal-to-noise ratio. (2) The final stage of the semiconductor amplifier does not employ a regulated power supply, as shown in Figure 2-26, which includes chokes and a 20,000 µF/50V electrolytic capacitor forming an LC filter network with a current rating of 1.5A. (3) The output transformer is designed for ease of production, utilizing a homemade laminated iron core measuring 24mm in width and 40mm in thickness, constructed from high-quality silicon. The primary winding consists of 200 turns, arranged as two series windings of 100 turns each, while the secondary winding comprises 100 turns. During actual production, two wires of 0.72mm and one wire of 1.02mm are used, ensuring high strength, and the windings are enveloped with three strands for stability, with clear identification of the start and end of the three windings.

The amplifier circuit operates on the principles of parallel push-pull amplification, which enhances efficiency and linearity by allowing both halves of the waveform to be amplified simultaneously. The class 6N11 tube is particularly effective in this application due to its favorable characteristics, including a high transconductance and low distortion, making it suitable for high-frequency signal processing.

The lack of a regulated power supply in the final stage allows for a more straightforward design, although it may introduce some ripple in the output. The LC filter network, comprised of chokes and a substantial electrolytic capacitor, serves to smooth out voltage fluctuations, ensuring a stable output for the amplifier. The choice of a 20,000 µF capacitor is significant, as it provides ample energy storage to handle transient demands during operation.

The output transformer is a critical component in this amplifier design. The use of a laminated iron core minimizes eddy current losses, which is essential for maintaining efficiency, especially at higher frequencies. The winding configuration is carefully designed to optimize inductance and impedance matching, with the primary side having two windings of 100 turns each, allowing for flexibility in the design and potential adjustments during assembly.

In terms of construction, the use of different wire gauges for the windings enhances the robustness of the transformer. The 0.72mm wire provides a solid foundation for the primary winding, while the 1.02mm wire in the secondary winding ensures that the transformer can handle the required power levels without overheating. The triple-strand enveloping technique not only adds mechanical strength but also aids in reducing electromagnetic interference, thereby improving overall performance. Proper identification of the winding ends is crucial for ensuring correct phasing during assembly, which directly impacts the amplifier's efficiency and sound quality.Amplifier circuit shown in Figure 2-25. It has the following features: (1) promote the use of a class 6N11 tube for parallel push-pull amplification entire term, high-frequency response, a letter -to-noise ratio. (2) The final stage of the semiconductor amplifier tube amplifier does not use regulated power supply, can be seen from Figure 2 26, chokes and 20000r1F/50V electrolytic capacitor 1. SH/1. 5A composition LC filter network power (3 ) output transformer production easy, use of the tongue when homemade 24mm wide, 40mm thick laminated iron core made of high-quality silicon, early -stage total of 200 turns, the series consists of two 100 turns winding; a secondary with 100 turns, when the actual production with two 1) 0.

72mm and a root of 1. 02mm double wire high strength and stitch around three strands envelope, identify the head and tail of the three windings.

The amplifier circuit operates on the principles of parallel push-pull amplification, which enhances efficiency and linearity by allowing both halves of the waveform to be amplified simultaneously. The class 6N11 tube is particularly effective in this application due to its favorable characteristics, including a high transconductance and low distortion, making it suitable for high-frequency signal processing.

The lack of a regulated power supply in the final stage allows for a more straightforward design, although it may introduce some ripple in the output. The LC filter network, comprised of chokes and a substantial electrolytic capacitor, serves to smooth out voltage fluctuations, ensuring a stable output for the amplifier. The choice of a 20,000 µF capacitor is significant, as it provides ample energy storage to handle transient demands during operation.

The output transformer is a critical component in this amplifier design. The use of a laminated iron core minimizes eddy current losses, which is essential for maintaining efficiency, especially at higher frequencies. The winding configuration is carefully designed to optimize inductance and impedance matching, with the primary side having two windings of 100 turns each, allowing for flexibility in the design and potential adjustments during assembly.

In terms of construction, the use of different wire gauges for the windings enhances the robustness of the transformer. The 0.72mm wire provides a solid foundation for the primary winding, while the 1.02mm wire in the secondary winding ensures that the transformer can handle the required power levels without overheating. The triple-strand enveloping technique not only adds mechanical strength but also aids in reducing electromagnetic interference, thereby improving overall performance. Proper identification of the winding ends is crucial for ensuring correct phasing during assembly, which directly impacts the amplifier's efficiency and sound quality.Amplifier circuit shown in Figure 2-25. It has the following features: (1) promote the use of a class 6N11 tube for parallel push-pull amplification entire term, high-frequency response, a letter -to-noise ratio. (2) The final stage of the semiconductor amplifier tube amplifier does not use regulated power supply, can be seen from Figure 2 26, chokes and 20000r1F/50V electrolytic capacitor 1. SH/1. 5A composition LC filter network power (3 ) output transformer production easy, use of the tongue when homemade 24mm wide, 40mm thick laminated iron core made of high-quality silicon, early -stage total of 200 turns, the series consists of two 100 turns winding; a secondary with 100 turns, when the actual production with two 1) 0.

72mm and a root of 1. 02mm double wire high strength and stitch around three strands envelope, identify the head and tail of the three windings.