working principles of motor control

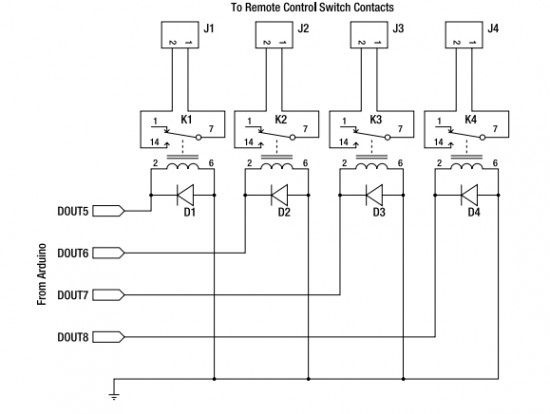

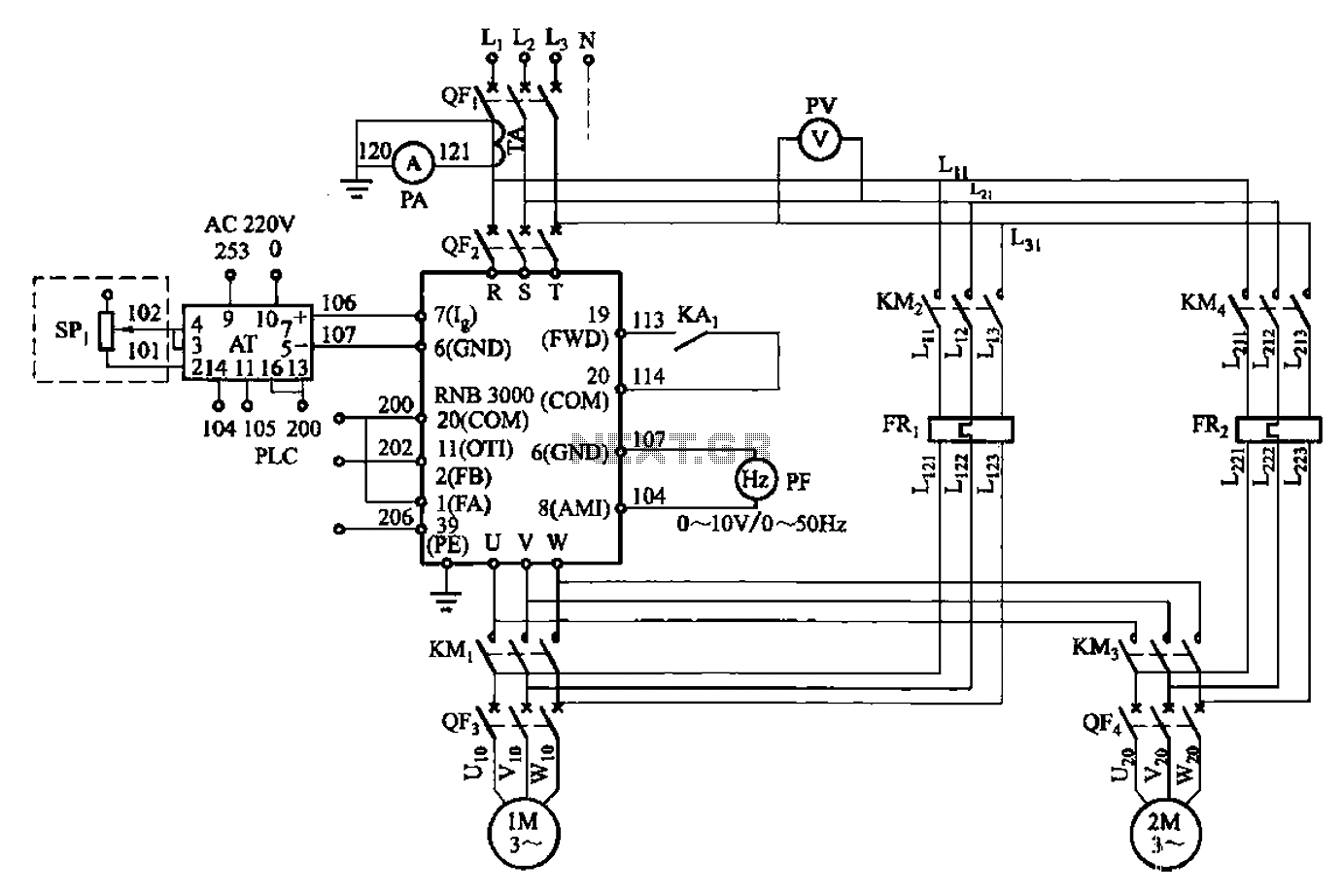

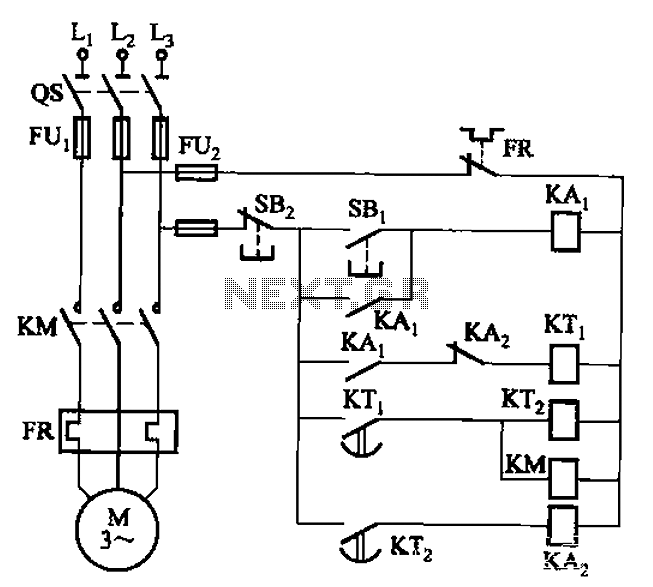

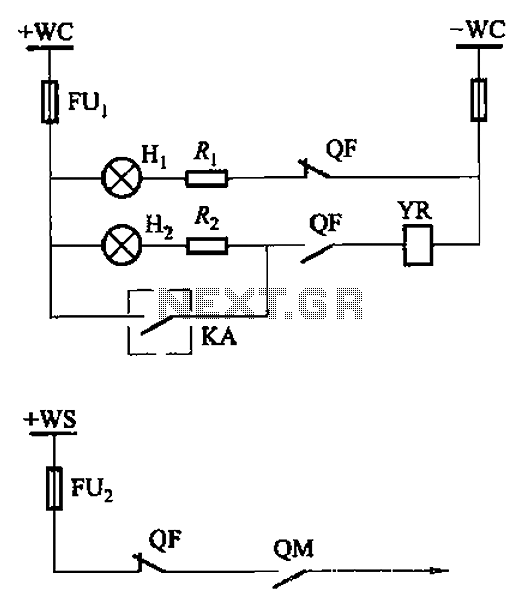

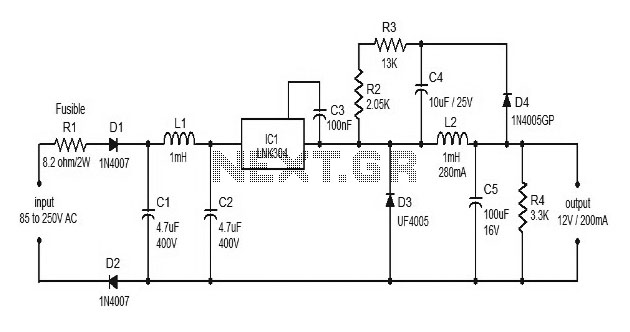

After dismantling a Chinese copy of a Segway, an examination of the motor controller was conducted. After several hours of work with a multimeter, pen, paper, and KiCad, a block diagram and schematic of the motor controller were developed. This motor controller is designed in a cost-effective and straightforward manner. Reverse engineering and analyzing this unit serve as an excellent method to learn the fundamentals of motor control. The motor controller consists of three main components: the motor controller board, the motor direction control board, and the main power relay. In the initial observation, the main power relay was removed, leaving an empty space between the boards. The main power relay and motor direction control board were secured to the bottom of the enclosure using double-sided duct tape, while the motor controller board was properly fixed in place, fitting into grooves along the walls of the box. The power transistors were mounted using a metal plate that was screwed to the wall. Due to a failure in the controller, the power MOSFETs were replaced, necessitating some modifications. Originally, the design included two MOSFETs and one freewheeling diode in a TO-220 package. In the absence of suitable diodes, two additional MOSFETs were used as a replacement. The original metal mounting plate was insufficient to accommodate four TO-220 devices, prompting the creation of a longer aluminum plate with an extra hole for secure mounting (as shown in the second image). The third image indicates that modifications were made to the bottom part of the board post-manufacture. One modification, a voltage delay circuit (consisting of a transistor, electrolytic capacitor, and resistor), was added by the device's assemblers, while another modification, a blue multi-turn potentiometer, was added to allow for adjustment of the over-current protection limit. This post focuses on the motor controller, which enables gradual adjustment of the motor's power in accordance with the throttle position. Although various methods exist for altering the electrical power applied to the motor, Pulse Width Modulation (PWM) is predominantly utilized in practice. The basic principle of PWM is straightforward: to apply no power to a device (whether it is a DC motor or a light bulb), the device is switched off (i.e., disconnected from the power source). To apply full power, the device is switched on (i.e., connected to the power source). For partial power application, the device is switched on and off continuously, remaining on for a specified percentage of the time and off for the remainder. For example, if the device is activated for 20 seconds and deactivated for 80 seconds, over time, this results in an effective power application of 20%. Two key parameters describe PWM: period/frequency and duty cycle. In this example, the period would be 100 seconds (20 seconds on plus 80 seconds off), resulting in a frequency of 0.01 Hz (since frequency is the inverse of the period). The duty cycle is calculated as 20% (20 seconds on divided by 100 seconds total). The duty cycle is the variable that controls the power delivered to the device, while frequency remains constant. The controller is equipped with additional over-current and under-voltage protection circuits. It is evident that the manufacturer incorporated an additional circuit after the controller's assembly, which limits the rapid increase of voltage from the throttle sensor. This modification prevents sudden power surges, giving the impression of a weaker powertrain. The motor controller can be divided into seven functional blocks (as illustrated in the block diagram): triangle wave generator, throttle, voltage delay circuit, comparator, under-voltage and over-voltage protection, gate driver, and power stage. The triangle wave generator produces a triangle wave.

The motor controller operates through a well-defined architecture, allowing for effective control of the motor's power output. The triangle wave generator serves as the timing reference for the PWM signal, generating a continuous triangle waveform that is essential for modulating the duty cycle. The throttle input, typically a potentiometer or similar device, provides a variable resistance that represents the desired power level. This input is processed through the voltage delay circuit, which smooths the throttle response to prevent abrupt changes in power delivery.

The comparator compares the output of the triangle wave generator with the throttle signal, determining when to switch the gate driver on or off. This action ultimately controls the power stage, which consists of the MOSFETs responsible for driving the motor. The under-voltage and over-voltage protection circuits monitor the supply voltage, ensuring that the system operates within safe limits and preventing damage to the components.

In summary, the motor controller's design exemplifies a practical approach to motor control, integrating essential protective features and allowing for precise power management through PWM techniques. The modifications made during the repair process highlight the adaptability of electronic designs, enabling them to be tailored to specific needs while maintaining functionality.After dismantling chinese copy of segway I wanted to check how the controller is made. After a couple of hours of work with multimeter, pen, a sheet of paper and Kicad I came up with a block diagram and schematic of motor controller. This motor controller is made in a cheap and a very simple way. Reverse engineering and analysing this unit is a ve ry good way to learn the basics of motor control. Here are some pictures of dismantled motor controller: Motor controller consists of three parts - motor controller board, motor direction control board and main power relay. You can see those parts in the first picture (main power relay was removed, thus there is empty space between boards).

Main power relay and motor direction control board were fixed to the botton of the box by double sided duct tape. Motor controller board was fixed properly. PCB was pushed in the grooves of the walls of a box. Power transistors were fixed by a metal plate which was screwed to the wall. Because this controller had burned, I changed power mosfets and had to modify this part a little bit.

Originally there were two mosfets and one freewheeling diode in TO-220 case. I did not have appropriate diodes by hand, so I replaced it with two mosfets. Original metal mounting plate was too short to hold four TO-220 devices. I had to make a longer aluminium plate and drill one extra hole to fix it properly to the wall (picture 2). As it is visible from the third picture, there were some modifications (at the bottom part of the board) done after the board was manufactured.

One modification, voltage delay circuit (transistor, electrolytic capacitor and resistor in picture 4) was made by assemblers of this device, and the other (blue multi-turn potentiometer) was made by me - it allows to change over-current protection limit. The topic of this post is motor controller, so only this part will be discussed further. This controller allows to change motor`s power gradually according to a throttle position. In theory there are many ways to change the applied electrical power to the motor, but in practice mostly PWM (Pulse With Modulation) tecnique is used.

Basic theory of PWM is very simple. If you want to apply zero/no power to a device (wether it is a DC motor or for example, a light bulb), you switch off the device (i. e. disconnect it from the power source). When you want to apply full power, you just switch the device on (i. e. connect it to a powe source). What would you do if you wanted to apply 20% of the power to the device in a specific period of time Very simple - by switching the device on and off continiously, switching it on for 20% of the time and off for the 80% of the time.

For example, if you switch the device on for 20 seconds, then switch it off for 80 seconds, then switch it on again for 20 seconds. In long term, this will be equal to applying 20% of the maximum power to the device. There are two parameters, that describe PWM: period/frequency and duty cycle. Period/frequency in given example would be 100 seconds(i. e. 20s+80s) or 0. 01Hz (frequency is measured in Hertz and equals 1/period), and duty cycle 20% (20/(20*80). Duty cycle is the parameter that changes controls the power applied to the device. Frequency does not make any difference in power. Controller has additional over-current and under-voltage protection circuits. It was clearly seen that for some reasons after the controller was build, manufacturer added additional circuit.

This circuit prevents voltage from throttle sensor to rise quickly. This does not allow to increase power rapidly, which makes it feel that the vehicles powertrain is weak. Motor controller could be divided into 7 functional blocks (refer to block diagram Image 1): triangle wave generator, throttle, voltage delay circuit, comparator, under-voltage and over-voltage protection, gate driver and power stage.

Triangle wave generator generates a triangle wave 🔗 External reference

The motor controller operates through a well-defined architecture, allowing for effective control of the motor's power output. The triangle wave generator serves as the timing reference for the PWM signal, generating a continuous triangle waveform that is essential for modulating the duty cycle. The throttle input, typically a potentiometer or similar device, provides a variable resistance that represents the desired power level. This input is processed through the voltage delay circuit, which smooths the throttle response to prevent abrupt changes in power delivery.

The comparator compares the output of the triangle wave generator with the throttle signal, determining when to switch the gate driver on or off. This action ultimately controls the power stage, which consists of the MOSFETs responsible for driving the motor. The under-voltage and over-voltage protection circuits monitor the supply voltage, ensuring that the system operates within safe limits and preventing damage to the components.

In summary, the motor controller's design exemplifies a practical approach to motor control, integrating essential protective features and allowing for precise power management through PWM techniques. The modifications made during the repair process highlight the adaptability of electronic designs, enabling them to be tailored to specific needs while maintaining functionality.After dismantling chinese copy of segway I wanted to check how the controller is made. After a couple of hours of work with multimeter, pen, a sheet of paper and Kicad I came up with a block diagram and schematic of motor controller. This motor controller is made in a cheap and a very simple way. Reverse engineering and analysing this unit is a ve ry good way to learn the basics of motor control. Here are some pictures of dismantled motor controller: Motor controller consists of three parts - motor controller board, motor direction control board and main power relay. You can see those parts in the first picture (main power relay was removed, thus there is empty space between boards).

Main power relay and motor direction control board were fixed to the botton of the box by double sided duct tape. Motor controller board was fixed properly. PCB was pushed in the grooves of the walls of a box. Power transistors were fixed by a metal plate which was screwed to the wall. Because this controller had burned, I changed power mosfets and had to modify this part a little bit.

Originally there were two mosfets and one freewheeling diode in TO-220 case. I did not have appropriate diodes by hand, so I replaced it with two mosfets. Original metal mounting plate was too short to hold four TO-220 devices. I had to make a longer aluminium plate and drill one extra hole to fix it properly to the wall (picture 2). As it is visible from the third picture, there were some modifications (at the bottom part of the board) done after the board was manufactured.

One modification, voltage delay circuit (transistor, electrolytic capacitor and resistor in picture 4) was made by assemblers of this device, and the other (blue multi-turn potentiometer) was made by me - it allows to change over-current protection limit. The topic of this post is motor controller, so only this part will be discussed further. This controller allows to change motor`s power gradually according to a throttle position. In theory there are many ways to change the applied electrical power to the motor, but in practice mostly PWM (Pulse With Modulation) tecnique is used.

Basic theory of PWM is very simple. If you want to apply zero/no power to a device (wether it is a DC motor or for example, a light bulb), you switch off the device (i. e. disconnect it from the power source). When you want to apply full power, you just switch the device on (i. e. connect it to a powe source). What would you do if you wanted to apply 20% of the power to the device in a specific period of time Very simple - by switching the device on and off continiously, switching it on for 20% of the time and off for the 80% of the time.

For example, if you switch the device on for 20 seconds, then switch it off for 80 seconds, then switch it on again for 20 seconds. In long term, this will be equal to applying 20% of the maximum power to the device. There are two parameters, that describe PWM: period/frequency and duty cycle. Period/frequency in given example would be 100 seconds(i. e. 20s+80s) or 0. 01Hz (frequency is measured in Hertz and equals 1/period), and duty cycle 20% (20/(20*80). Duty cycle is the parameter that changes controls the power applied to the device. Frequency does not make any difference in power. Controller has additional over-current and under-voltage protection circuits. It was clearly seen that for some reasons after the controller was build, manufacturer added additional circuit.

This circuit prevents voltage from throttle sensor to rise quickly. This does not allow to increase power rapidly, which makes it feel that the vehicles powertrain is weak. Motor controller could be divided into 7 functional blocks (refer to block diagram Image 1): triangle wave generator, throttle, voltage delay circuit, comparator, under-voltage and over-voltage protection, gate driver and power stage.

Triangle wave generator generates a triangle wave 🔗 External reference