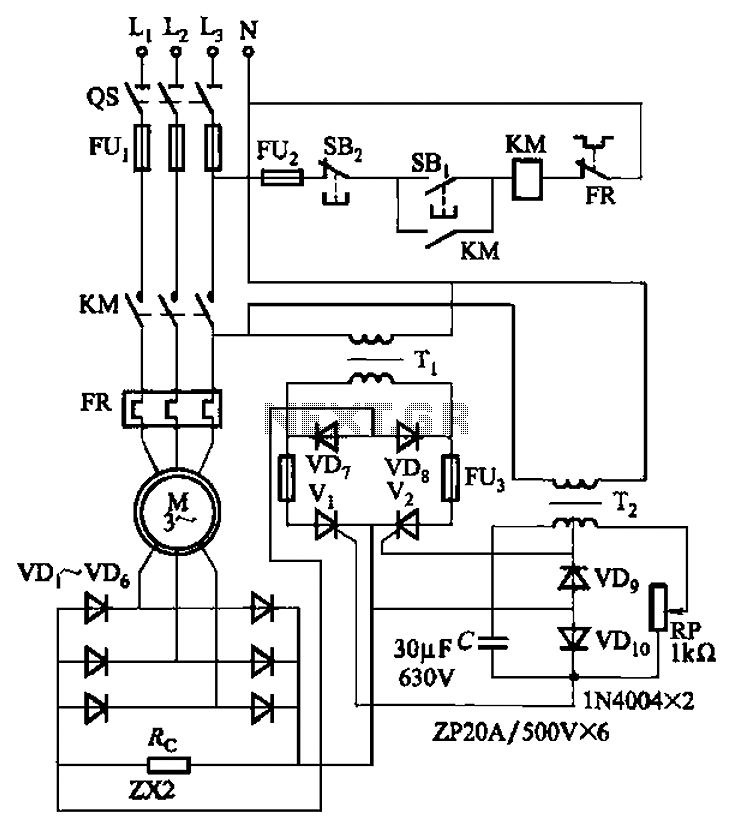

Auxiliary power supply circuit using variable speed

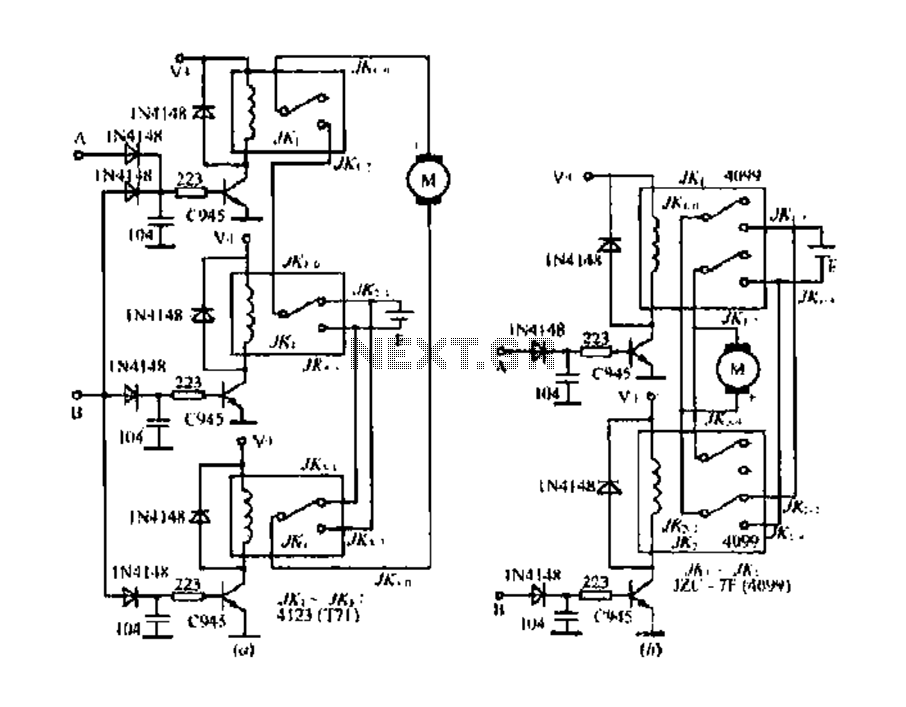

The circuit depicted in Figure 3-171 includes an auxiliary power supply that operates on single-phase AC power. It features a single-phase half-wave controlled bridge composed of diodes VD7, VD8, and thyristors V1, V2. The output current is managed by a balancing resistor R. The thyristor trigger circuit employs a full-wave bridge configuration with resistive and capacitive phase shifting. An adjustment potentiometer RP is included to modify the conduction angle of the thyristor, allowing for continuous adjustment of the motor speed within a range of 300 to 900 RPM.

The circuit operates using a single-phase AC power source, which is rectified by the half-wave controlled bridge. The controlled bridge consists of two diodes (VD7 and VD8) and two thyristors (V1 and V2). In this configuration, the diodes conduct during one half of the AC cycle, while the thyristors are triggered to conduct during the other half, allowing for control over the output voltage and current supplied to the load, which in this case is a motor.

The balancing resistor R is essential for ensuring that the output current is evenly distributed between the components of the bridge. This helps maintain stability in the circuit and prevents excessive current from flowing through any single component, thereby enhancing reliability and performance.

The thyristor trigger circuit is designed to provide precise control over the conduction angle of the thyristors. By utilizing a full-wave bridge configuration along with resistive and capacitive phase shifting, the trigger circuit can adjust the timing of the thyristor firing. The adjustment potentiometer RP allows the user to set the desired conduction angle, which directly influences the average output voltage and, consequently, the speed of the motor.

This circuit is particularly useful in applications requiring variable speed control, as it enables the motor to operate smoothly across a broad range of speeds from 300 RPM to 900 RPM. The ability to finely tune the speed through the adjustment of the conduction angle makes this circuit suitable for various industrial and automation applications where precise motor control is necessary. Circuit shown in Figure 3-171. The figure, the auxiliary power supply is single-phase AC power, the single-phase half-wave controlled bridge (diode VD7, VD8 and thyristor vl, V 2 composition) output current supply balancing resistor R. Thyristor trigger circuit is a full -wave bridge resistive and capacitive phase shift. Adjustment potentiometer RP, can change the trigger thyristor conduction angle, thereby enabling the motor can be 300 ~ 900r/min continuously adjustable within range.

The circuit operates using a single-phase AC power source, which is rectified by the half-wave controlled bridge. The controlled bridge consists of two diodes (VD7 and VD8) and two thyristors (V1 and V2). In this configuration, the diodes conduct during one half of the AC cycle, while the thyristors are triggered to conduct during the other half, allowing for control over the output voltage and current supplied to the load, which in this case is a motor.

The balancing resistor R is essential for ensuring that the output current is evenly distributed between the components of the bridge. This helps maintain stability in the circuit and prevents excessive current from flowing through any single component, thereby enhancing reliability and performance.

The thyristor trigger circuit is designed to provide precise control over the conduction angle of the thyristors. By utilizing a full-wave bridge configuration along with resistive and capacitive phase shifting, the trigger circuit can adjust the timing of the thyristor firing. The adjustment potentiometer RP allows the user to set the desired conduction angle, which directly influences the average output voltage and, consequently, the speed of the motor.

This circuit is particularly useful in applications requiring variable speed control, as it enables the motor to operate smoothly across a broad range of speeds from 300 RPM to 900 RPM. The ability to finely tune the speed through the adjustment of the conduction angle makes this circuit suitable for various industrial and automation applications where precise motor control is necessary. Circuit shown in Figure 3-171. The figure, the auxiliary power supply is single-phase AC power, the single-phase half-wave controlled bridge (diode VD7, VD8 and thyristor vl, V 2 composition) output current supply balancing resistor R. Thyristor trigger circuit is a full -wave bridge resistive and capacitive phase shift. Adjustment potentiometer RP, can change the trigger thyristor conduction angle, thereby enabling the motor can be 300 ~ 900r/min continuously adjustable within range.