One of debug circuitry DC motor armature resistance in series starting

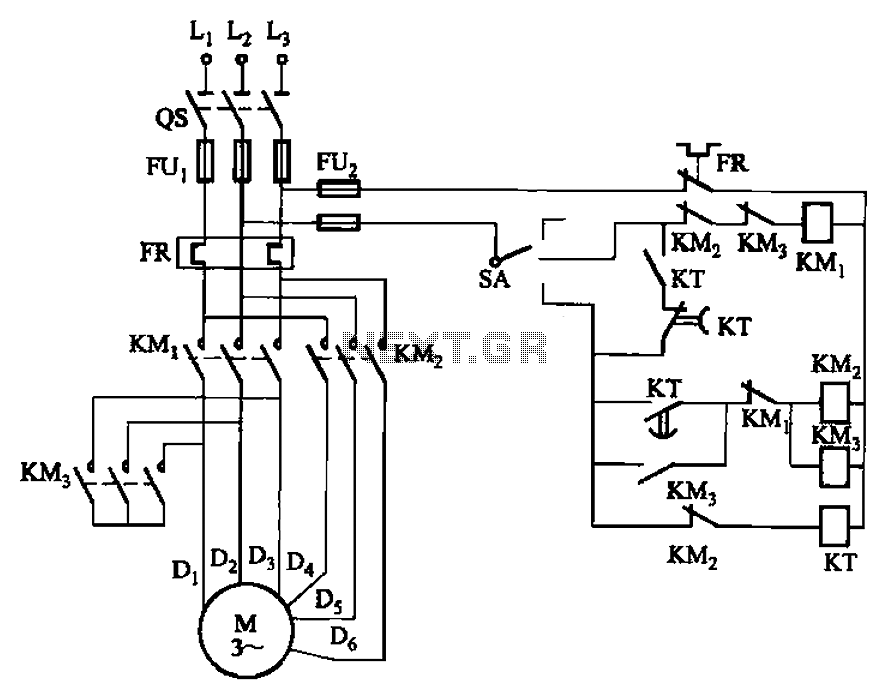

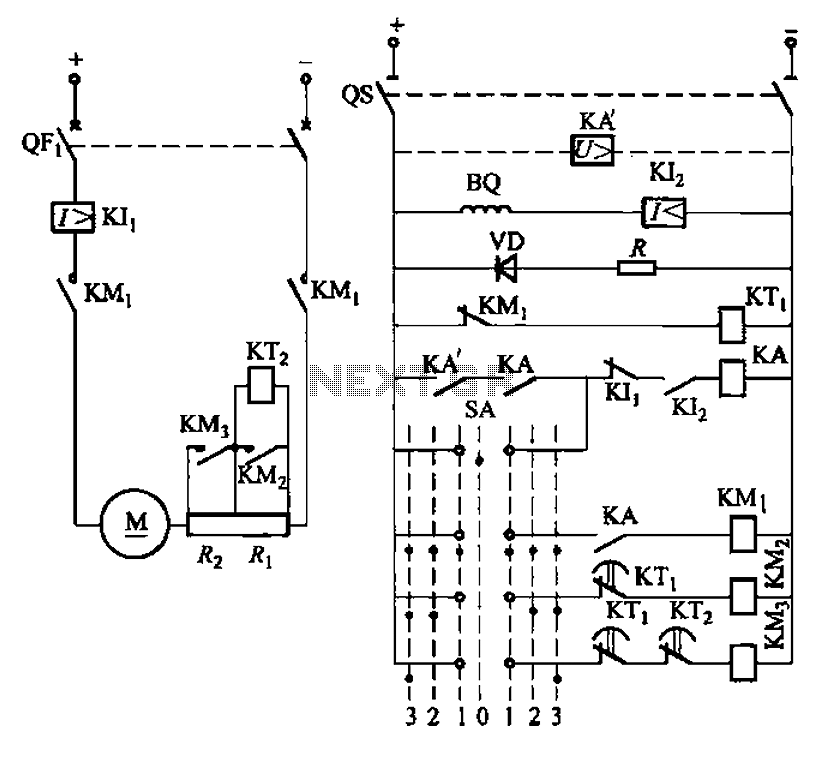

The circuit depicted in Figure 3-190 includes an armature circuit with two startup resistors, Ri and Rz, connected in series through the main switch SA to facilitate starting, stopping, and speed control. During the startup phase, two relays, KTi and KTz, automatically disconnect the startup resistors after a predetermined time. The circuit also incorporates over-current protection (KIl) and weakening protection (KI2). Intermediate relays KA and KA are used for under-voltage protection. At startup, the main switch SA is moved from the 0 position to the 1 position, allowing the startup resistors Ri and Rz to connect to the armature circuit. After a delay determined by KTi, resistor Ri is shorted, followed by a further delay (as determined by KT2) after which resistor Rz is also shorted, allowing full voltage to reach the motor at the end of the startup process. For deceleration, the master switch SA can be set to positions 2 or 3, enabling the motor armature to operate at reduced levels or resistance levels.

The circuit design illustrated in Figure 3-190 is a robust solution for controlling the operation of a motor through an armature circuit. The configuration of two startup resistors, Ri and Rz, serves to limit the inrush current during the initial startup phase, which is critical for protecting the motor and associated components from damage due to excessive current draw. The relays KTi and KTz play a pivotal role in the automatic disconnection of these resistors, ensuring that the motor transitions smoothly to full operational voltage after the startup phase.

The integration of over-current protection (KIl) and weakening protection (KI2) enhances the reliability of the system by providing safeguards against conditions that could lead to motor failure. The intermediate relays KA and KA are essential for monitoring under-voltage conditions, which can prevent potential damage caused by insufficient voltage levels during operation.

The functionality of the main switch SA is crucial in this circuit. By shifting the switch from the 0 position to the 1 position, the operator initiates the startup sequence. The timing of the relays is carefully calibrated to ensure that the resistors are shorted at the correct intervals, allowing the motor to reach its full operational capacity without undue stress. The option to adjust the master switch SA to positions 2 or 3 provides flexibility in controlling the motor's speed and torque by varying the resistance in the armature circuit, thereby allowing for tailored performance based on specific operational requirements.

Overall, this circuit design exemplifies a well-thought-out approach to motor control, incorporating essential protective measures and providing adjustable operational parameters to meet diverse application needs. Circuit shown in Figure 3-190. The line in the armature circuit in series two startup resistor Ri, Rz, through the main switch SA to achieve start, stop and speed control. Duri ng startup time by two relays KTi, KTz automatically cut two segments startup resistor. With over-current protection circuit (KIl) and weakening protection (KI2). Intermediate relay KA, KA for the under voltage relay. At startup, the SA from 0 position hit the 1 position, the startup resistor Ri, Rz have access armature circuit via a delay after paragraph (determined by KTi) short of Ri, and then after a delay ( KT2 decision) by the short and the Rz, electric full voltage running into the motive, the end of the boot process. If desired deceleration can be master switch SA is set to 2 or 3 position, the motor armature in series level or resistance levels run under.

The circuit design illustrated in Figure 3-190 is a robust solution for controlling the operation of a motor through an armature circuit. The configuration of two startup resistors, Ri and Rz, serves to limit the inrush current during the initial startup phase, which is critical for protecting the motor and associated components from damage due to excessive current draw. The relays KTi and KTz play a pivotal role in the automatic disconnection of these resistors, ensuring that the motor transitions smoothly to full operational voltage after the startup phase.

The integration of over-current protection (KIl) and weakening protection (KI2) enhances the reliability of the system by providing safeguards against conditions that could lead to motor failure. The intermediate relays KA and KA are essential for monitoring under-voltage conditions, which can prevent potential damage caused by insufficient voltage levels during operation.

The functionality of the main switch SA is crucial in this circuit. By shifting the switch from the 0 position to the 1 position, the operator initiates the startup sequence. The timing of the relays is carefully calibrated to ensure that the resistors are shorted at the correct intervals, allowing the motor to reach its full operational capacity without undue stress. The option to adjust the master switch SA to positions 2 or 3 provides flexibility in controlling the motor's speed and torque by varying the resistance in the armature circuit, thereby allowing for tailored performance based on specific operational requirements.

Overall, this circuit design exemplifies a well-thought-out approach to motor control, incorporating essential protective measures and providing adjustable operational parameters to meet diverse application needs. Circuit shown in Figure 3-190. The line in the armature circuit in series two startup resistor Ri, Rz, through the main switch SA to achieve start, stop and speed control. Duri ng startup time by two relays KTi, KTz automatically cut two segments startup resistor. With over-current protection circuit (KIl) and weakening protection (KI2). Intermediate relay KA, KA for the under voltage relay. At startup, the SA from 0 position hit the 1 position, the startup resistor Ri, Rz have access armature circuit via a delay after paragraph (determined by KTi) short of Ri, and then after a delay ( KT2 decision) by the short and the Rz, electric full voltage running into the motive, the end of the boot process. If desired deceleration can be master switch SA is set to 2 or 3 position, the motor armature in series level or resistance levels run under.