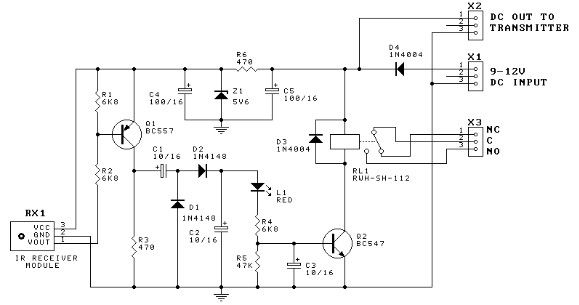

The main circuit in order to start the control circuit

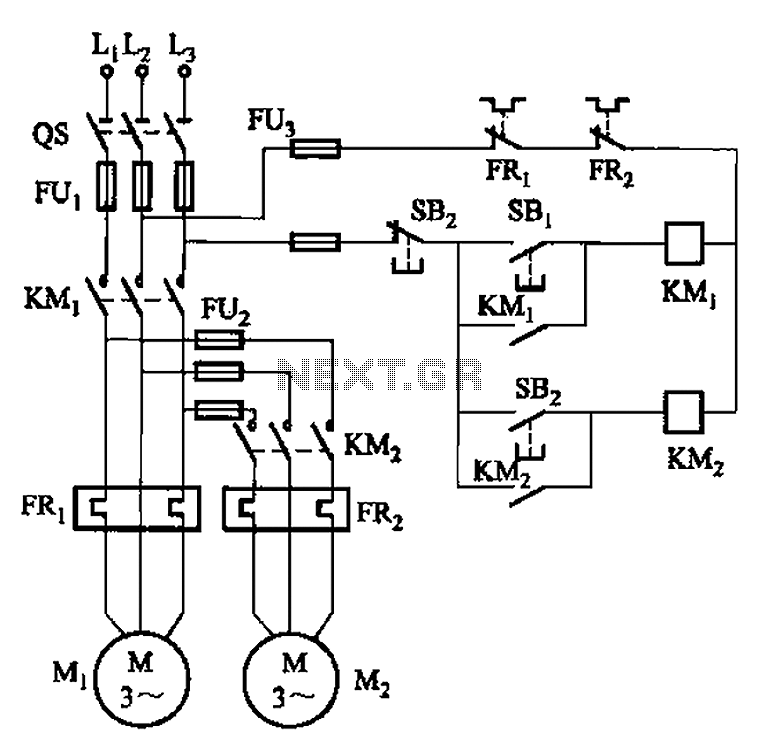

The circuit illustrated in Figure 3-83 demonstrates that the contactor KMi is activated only after it is pulled, which indicates that the motor Mi has started for the first time. Following this, the contactor KM2 is then activated, indicating that the motor Mz has started.

The circuit operates as a sequential motor control system where the activation of the first motor (Mi) is crucial for the subsequent activation of the second motor (Mz). The contactor KMi serves as a primary control switch that engages the first motor. Upon successful activation of motor Mi, the contactor KM2 is engaged, allowing the second motor (Mz) to start.

The configuration typically includes control relays and overload protection devices to ensure safe operation. For instance, overload relays may be integrated to prevent damage to the motors due to excessive current draw. Additionally, interlocking mechanisms can be utilized to ensure that both motors do not operate simultaneously unless specified, enhancing the safety and reliability of the circuit.

The schematic may also depict auxiliary contacts associated with the contactors, which provide feedback to the control circuit, indicating the operational status of each motor. This feedback is essential for monitoring and controlling the system effectively, enabling the implementation of further automation or control strategies as needed.

In summary, the circuit design emphasizes a controlled startup sequence for multiple motors, minimizing the risk of electrical faults and ensuring efficient operation. Circuit shown in Figure 3-83. The figure shows that only when the contactor KMi after pull (ie, after the motor Mi first start), KM2 to pull (ie Mz after start)

The circuit operates as a sequential motor control system where the activation of the first motor (Mi) is crucial for the subsequent activation of the second motor (Mz). The contactor KMi serves as a primary control switch that engages the first motor. Upon successful activation of motor Mi, the contactor KM2 is engaged, allowing the second motor (Mz) to start.

The configuration typically includes control relays and overload protection devices to ensure safe operation. For instance, overload relays may be integrated to prevent damage to the motors due to excessive current draw. Additionally, interlocking mechanisms can be utilized to ensure that both motors do not operate simultaneously unless specified, enhancing the safety and reliability of the circuit.

The schematic may also depict auxiliary contacts associated with the contactors, which provide feedback to the control circuit, indicating the operational status of each motor. This feedback is essential for monitoring and controlling the system effectively, enabling the implementation of further automation or control strategies as needed.

In summary, the circuit design emphasizes a controlled startup sequence for multiple motors, minimizing the risk of electrical faults and ensuring efficient operation. Circuit shown in Figure 3-83. The figure shows that only when the contactor KMi after pull (ie, after the motor Mi first start), KM2 to pull (ie Mz after start)