3-6V Xenon Strobe Light

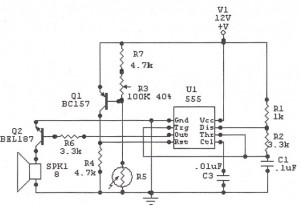

This circuit was originally available as a kit from a surplus supplier, but it is likely no longer obtainable. It incorporates several innovative concepts, such as utilizing a 555 timer as a pulse width modulator (PWM) and employing series/parallel configurations of camera flash transformers. Caution is advised, as the circuit operates at voltages and currents that can be lethal if not handled properly. Charged capacitors can retain a dangerous charge for hours. Individuals with limited experience working with high voltages or those who are not comfortable with such risks should refrain from attempting to construct this circuit. The 555 timer is configured as a PWM, with the off time adjusted by a trimmer. The output from pin 3 is connected to the gate of a P-channel MOSFET (IRF9Z20) through a 100-ohm resistor to prevent parasitic oscillations. A low signal at pin 3 activates the MOSFET, allowing the potentiometer to regulate the output power and influence the flash frequency by varying the duty cycle of the 555 timer and the MOSFET. The drain of the MOSFET connects to the primaries of four camera flash transformers (T1-T4), which are wired in series and designed for 3V operation, enabling a 12V input. In this series/parallel setup, the secondaries of T1-T4 are connected in parallel, providing approximately 330V at four times the current due to the four transformers. This voltage is rectified by a 1N4005 diode and stored in a 150µF capacitor. Additionally, the 6.9nF and 12nF capacitors are charged. When the 6.8nF capacitor reaches the strike voltage of the neon lamp (approximately 60V), it discharges into the gate of a silicon-controlled rectifier (SCR), activating it. This triggers the discharge of the 12nF capacitor into the primary of the trigger transformer (T5), which steps up the voltage to around 3kV, applied to the glass envelope of the Xenon flash tube. This high voltage ionizes the gas inside the tube, creating a conductive path for discharging the 150µF capacitor. The 2.8µH inductor extends the discharge duration, resulting in a longer flash. The circuit illustrates the 555 timer's capability as a PWM. The schematic shows two diodes connected between pins 2/6 and pin 7. A 3k potentiometer is configured to set the 555's on time (the off time of the MOSFET), and an additional potentiometer can be connected between pin 7 and the other diode to adjust the off time. In the current schematic arrangement, the off time is effectively fixed. The MOSFET remains on during the 555's off state, as pin 3 connects to ground, resulting in a low signal. When the 555 timer returns to high voltage, the internal capacitance of the MOSFET discharges, turning it off. Unlike bipolar junction transistors, which turn off when base current is removed, field-effect transistors (FETs) maintain a charge between the gate and channel. Thus, simply disconnecting the voltage source does not deactivate the FET due to this capacitance. If the gate input does not discharge this capacitor, a pull-up (for P-channel) or pull-down (for N-channel) resistor may be necessary. In this circuit, the 555 timer manages the gate voltage, eliminating the need for additional resistors. The transformers (T1-T4) are four identical Kodak Ektralite camera flash transformers, which utilize ferrite cores typical of camera flash transformers.

This circuit design effectively demonstrates the functionality of the 555 timer in PWM applications while employing high-voltage components safely and efficiently. The careful arrangement of components, including the MOSFET, transformers, capacitors, and diodes, ensures the desired operation of the flash circuit while highlighting the importance of safety measures when dealing with high voltages. Proper understanding of the circuit operation and component behavior is essential for anyone considering replicating or modifying this design.This circuit used to come as a kit from a surplus supplier, but probably isn`t available anymore. It shows a few novel concepts such as using a 555 as a pulse width modulator (PWM), and series/parallel camera flash transformers. WARNING: This circuit is contains voltages and currents which can KILL if you are not careful. Charged capacitors will S URPRISE YOU! They can hold a lethal charge for hours! If you don`t know much about working with high voltages or if you aren`t crazy (like me) then DO NOT attempt to construct this circuit. I CANNOT BE RESPONSIBLE if you electrocute yourself to death! That said, let`s have some fun! The 555 is set up as a pulse width modulator (the off (low) time being set by the trimmer). The output at pin 3 is connected to the gate of the P-channel MOSFET (IRF9Z20) through the 100R resistor to prevent parasitic oscillation of the transistor.

A low signal at pin 3 causes the MOSFET to turn on, thus the potentiometer controls the output power, and somewhat the flash frequency, by varying the duty cycle of the 555 and in turn the MOSFET. The drain of the MOSFET transistor is connected to the primaries of T1-T4 - the camera flash transformers.

These primary windings are connected in series, and being originally intended to operate at 3V, this allows an input voltage of 12V. In this particular series/parallel configuration, the secondaries of T1-T4 are connected in parallel, supplying approximately their rated 330V, but at 4 times the current since there are 4 of them.

This is rectified by the 1N4005 diode and passed along to the 150u storage capacitor. Also, the 6n9 and 12n capacitors are charged. Once the 6n8 cap reaches the strike voltage of the neon lamp, which is approximately 60V, it is dumped into the gate of the SCR, turning it on. This in turn dumps the 12n capacitor into the primary of the trigger transformer, T5. This is stepped up to around 3kV and applied to the glass envelope of the Xenon flash tube. Through the capacitance of the glass, this voltage is passed through to the Xenon gas inside, ionizing it and creating a conductive channel for the discharge of the 150u capacitor.

The 2u8 inductor widens out this discharge, creating a slightly longer flash. This circuit demonstrates how the 555 can be used as a PWM. You can see in the schematic how the two diodes are connected between pins 2/6 and pin 7. The 3k potentiometer connected as shown sets the on time of the 555 (Off time of the MOSFET), but if another potentiometer is connected between pin 7 and the other diode, the off time can also be adjusted. The way the circuit is drawn in the schematic above, the off time is basically fixed. The MOSFET is on during the off time of the 555 because when it`s off, pin 3 is connected to ground, so another way of saying it is that it goes low.

Then when the 555 goes high again, or back to positive rail voltage, the internal capacitance of the MOSFET is shorted out which shuts it off. Everyone seems to assume people know this. It`s different from regular bipolar junction transistors because in a bipolar, if you disconnect base current, it conveniently just shuts off as long as there is no current flowing.

Now, because of the way a FET works, there is a sort of capacitor formed between the gate and channel. Just removing the voltage source does not shut the FET down. This is because of the capacitor, the electric field is still present and it just keeps going. So if your gate input doesn`t discharge this capacitor, you will need to use what is called a or pull up (P-channel) or pull down (N-channel) resistor beteween the gate and source.

In this case though, we don`t need it because the 555 automatically pulls itself up and down for us. Gotta love that 555! T1-T4 are 4 identical Kodak Ektralite camera flash transformers. The brand name isn`t important, just that they`re itentical. They have ferrite cores like most camera flash transformer 🔗 External reference

This circuit design effectively demonstrates the functionality of the 555 timer in PWM applications while employing high-voltage components safely and efficiently. The careful arrangement of components, including the MOSFET, transformers, capacitors, and diodes, ensures the desired operation of the flash circuit while highlighting the importance of safety measures when dealing with high voltages. Proper understanding of the circuit operation and component behavior is essential for anyone considering replicating or modifying this design.This circuit used to come as a kit from a surplus supplier, but probably isn`t available anymore. It shows a few novel concepts such as using a 555 as a pulse width modulator (PWM), and series/parallel camera flash transformers. WARNING: This circuit is contains voltages and currents which can KILL if you are not careful. Charged capacitors will S URPRISE YOU! They can hold a lethal charge for hours! If you don`t know much about working with high voltages or if you aren`t crazy (like me) then DO NOT attempt to construct this circuit. I CANNOT BE RESPONSIBLE if you electrocute yourself to death! That said, let`s have some fun! The 555 is set up as a pulse width modulator (the off (low) time being set by the trimmer). The output at pin 3 is connected to the gate of the P-channel MOSFET (IRF9Z20) through the 100R resistor to prevent parasitic oscillation of the transistor.

A low signal at pin 3 causes the MOSFET to turn on, thus the potentiometer controls the output power, and somewhat the flash frequency, by varying the duty cycle of the 555 and in turn the MOSFET. The drain of the MOSFET transistor is connected to the primaries of T1-T4 - the camera flash transformers.

These primary windings are connected in series, and being originally intended to operate at 3V, this allows an input voltage of 12V. In this particular series/parallel configuration, the secondaries of T1-T4 are connected in parallel, supplying approximately their rated 330V, but at 4 times the current since there are 4 of them.

This is rectified by the 1N4005 diode and passed along to the 150u storage capacitor. Also, the 6n9 and 12n capacitors are charged. Once the 6n8 cap reaches the strike voltage of the neon lamp, which is approximately 60V, it is dumped into the gate of the SCR, turning it on. This in turn dumps the 12n capacitor into the primary of the trigger transformer, T5. This is stepped up to around 3kV and applied to the glass envelope of the Xenon flash tube. Through the capacitance of the glass, this voltage is passed through to the Xenon gas inside, ionizing it and creating a conductive channel for the discharge of the 150u capacitor.

The 2u8 inductor widens out this discharge, creating a slightly longer flash. This circuit demonstrates how the 555 can be used as a PWM. You can see in the schematic how the two diodes are connected between pins 2/6 and pin 7. The 3k potentiometer connected as shown sets the on time of the 555 (Off time of the MOSFET), but if another potentiometer is connected between pin 7 and the other diode, the off time can also be adjusted. The way the circuit is drawn in the schematic above, the off time is basically fixed. The MOSFET is on during the off time of the 555 because when it`s off, pin 3 is connected to ground, so another way of saying it is that it goes low.

Then when the 555 goes high again, or back to positive rail voltage, the internal capacitance of the MOSFET is shorted out which shuts it off. Everyone seems to assume people know this. It`s different from regular bipolar junction transistors because in a bipolar, if you disconnect base current, it conveniently just shuts off as long as there is no current flowing.

Now, because of the way a FET works, there is a sort of capacitor formed between the gate and channel. Just removing the voltage source does not shut the FET down. This is because of the capacitor, the electric field is still present and it just keeps going. So if your gate input doesn`t discharge this capacitor, you will need to use what is called a or pull up (P-channel) or pull down (N-channel) resistor beteween the gate and source.

In this case though, we don`t need it because the 555 automatically pulls itself up and down for us. Gotta love that 555! T1-T4 are 4 identical Kodak Ektralite camera flash transformers. The brand name isn`t important, just that they`re itentical. They have ferrite cores like most camera flash transformer 🔗 External reference