5-motor walker circuit

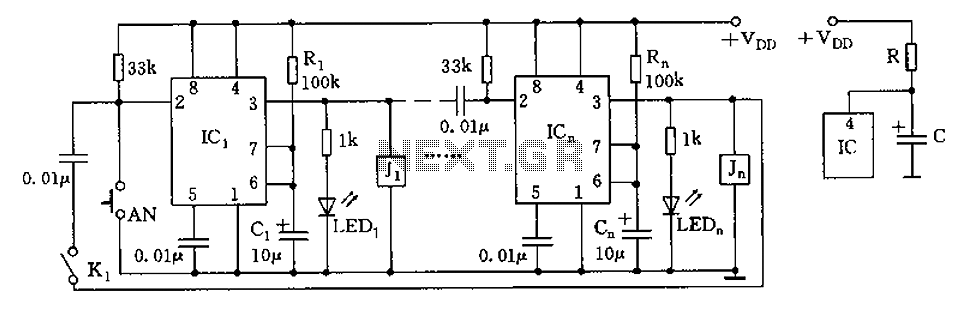

The P5 design utilizes eight 74HC/AC240 chips, which function as octal inverting buffers. Each 74HC/AC240 chip contains two groups of four inverters, each managed by a tri-state enable pin (pins 1 and 19). The 74AC240 chips (U1-U5) serve as H-bridge motor drivers, offering nearly double the drive current compared to the 74HC240 chips. These driver chips are permanently activated by grounding control pins 1 and 19. Each group consists of four inputs connected to a bicore output, with the outputs linked to a single motor winding terminal. The bicore's two complementary outputs create a voltage across the motor winding, enabling the motor to rotate in both directions. The 74HC240 chips U6 and U7 form a master-slave bicore pair with a reverser. The inverters for the bicore are permanently enabled by grounding pin 1, while the reversing inverters are controlled via the tri-state enable pin 19. Only two of the four tri-state inverters are conventionally employed for reversing the phase of the slave bicore, while the other two serve unique functions: one provides positive feedback to the enable pin, and the second activates a RED flashing LED when the reverser is engaged, serving as a diagnostic indicator for the operation of the slave bicore. The 74HC240 chip U8 includes a reverser and a slave bicore for the waist motor, along with a monocore (also known as a High-Low Oscillator) photobridge comparator that regulates the phasing of the front and rear motors. The photobridge comparator employs two inverters from U8 connected in series as a voltage-controlled oscillator, generating three states: if the left photodiode receives more light than the right, the two inverter outputs are steady-state DC, causing the left slave bicore and corresponding rear leg to reverse, resulting in a left turn. Conversely, if the right photodiode receives more light than the left, the outputs are steady-state DC in the opposite configuration, reversing the right slave bicore and causing a right turn. If both photodiodes receive equal light, the outputs pulse, and neither slave bicore reverses, allowing the walker to move straight. Two master suspended bicore circuits in U5 and U6 are coupled at their inputs with a 7.2M phase sync resistor, causing them to oscillate in quadrature with overlapping waveforms by 25%. These waveforms are connected to the 74AC240 motor driver controlling the front legs. Two rear motor slave bicore circuits utilize inverters from U5 and U6, with timing components that delay the slave bicore output by approximately 25%, linking them to the front leg motor drivers (six inverters for each motor). Two inverters in U6 and U7 facilitate signal reversing, connecting the outputs of each master bicore (front legs) to the slave bicore (rear legs) to manage turning based on enable signals from the photo comparator circuit. When light levels are balanced, pin 19 of U6 and U7 are high, disabling both reversers and the tri-state inverters, allowing the walker to proceed straight. The waist reverser employs two inverters in U8, connecting one output from each of the U6 and U7 master bicore circuits to the waist slave bicore circuit inputs. The waist motor phase reversal is triggered when one of two tactile switches activates upon colliding with an obstacle, enabling the U8 tri-state inverters. The power supply comprises a 6V NiCd battery and a charger circuit, featuring a three-position switch for on-off and charging operations. A 78L05 voltage regulator is included for recharging a 900mAHr battery pack at a rate of 0.1C without requiring removal from the walker.

The P5 design effectively integrates a series of 74HC/AC240 chips to create a versatile control system for motor operations. The use of H-bridge configurations allows for efficient control of motor direction and speed, facilitating the movement of the robotic walker. The incorporation of photodiodes for light detection enhances the walker’s ability to navigate its environment, enabling it to respond dynamically to changes in light intensity. The design's master-slave configuration ensures synchronized operation of the motors, while the unique application of tri-state inverters for feedback and LED indication provides additional functionality. The power management system is designed for convenience and efficiency, ensuring that the walker remains operational without the need for frequent battery removal. Overall, the P5 design exemplifies a well-thought-out approach to robotic motor control, combining various electronic components to achieve a cohesive and functional system.The P5 design uses only eight 74HC/AC240 chips which are all octal inverting buffers. Each 74HC/AC240 chip has two groups of four inverters each controlled by a tri-state enable pin (pin 1 and 19). The 74AC240 chips (U1-U5) are used as H-bridge style motor drivers since they have almost double the drive current compared to 74HC240 chips.

These mot or driver chips are permanently enabled by grounding control pins 1 and 19. The two groups each have four inputs connected in common to a bicore output and the four outputs are connected in common to one motor winding terminal. Since each bicore has two complementary outputs the voltage across the motor winding causes the motor to rotate back and forth.

The 74HC240 chips U6 and U7 are each used to form a master - slave bicore pair with reverser. The inverters used for the bicore s are permanently enabled by grounding pin 1. The inverters used for reversing are turned on or off with the tri-state enable pin 19. Only 2 of the 4 tristate inverters are used conventionally for reversing the phase of the slave bicore s while the other two are put to a novel use: one inverter is used to provide positive feedback to the enable pin and the second spare inverter is used to turn on a RED flashing LED when the reverser is active. The flashing LED also provides diagnostic visual indication of the operation of the slave bicore. The 74HC240 chip used for U8 provides a reverser and a slave bicore for the waist motor as well as a monocore (a.

k. a High Low Oscillator) photobridge comparator which controls the phasing of the front and rear motors. I) The photobridge comparator uses 2 inverter s from U8 connected in series as an voltage controlled oscillator with complementary outputs to generate three states : If the left photodiode gets more light than the right photodiode, the two inverter complementary outputs are steady state DC.

The inverter with the low output reverses the left slave bicore and corresponding rear leg causing the walker to turn left. If the right photodiode gets more light than the left photodiode, the two inverter complementary outputs are steady state DC (opposite to a.

) The inverter with the low output "reverses" the right slave bicore causing the walker to turn right. If both photodiode s get equal light, the two inverter complementary outputs are pulsing and neither of the slave bicore s is reversed causing the walker to go straight.

II) Two master suspended bicore s in U5 and 6 are coupled at their inputs with a 7. 2M phase sync resistor so that they will oscillate in quadrature with their waveforms overlapping by 25%. These waveforms are connected to the 74AC240 motor driver which control the front legs. III) Two rear motor slave bicore s use inverter s from U5 an U6 with timing components that delay the slave bicore output by about 25%.

These are connected to the front leg motor drivers (6 inverters for each motor). IV) Two inverters in U6 and U7 are used for signal reversing and are connected between the outputs of each of the master bicore s (front legs) and the slave bicore s (rear legs) to control turning with enable signals from the photo comparator circuit. When the light is balanced pin 19 of U6 and U7 are both high, both reversers are turned off, the tristate inverter s are disabled and the walker moves straight.

VI) The waist reverser uses two inverter s in U8 and is connected between one output of each of the U6 and U7 master bicore s and the waist slave bicore circuit inputs described in V). The waist motor phase reversal occurs when one of two tactile switches is triggered by collision with an obstacle.

At that time the U8 tristate inverter s are enabled. VII) The power supply consists of a 6V NiCd battery and charger circuit with a three position switch for on-off and charging. A 78L05 is included for recharging a 900mAHr battery pack at 0. 1C without removing it from the walker. The photo compar 🔗 External reference

The P5 design effectively integrates a series of 74HC/AC240 chips to create a versatile control system for motor operations. The use of H-bridge configurations allows for efficient control of motor direction and speed, facilitating the movement of the robotic walker. The incorporation of photodiodes for light detection enhances the walker’s ability to navigate its environment, enabling it to respond dynamically to changes in light intensity. The design's master-slave configuration ensures synchronized operation of the motors, while the unique application of tri-state inverters for feedback and LED indication provides additional functionality. The power management system is designed for convenience and efficiency, ensuring that the walker remains operational without the need for frequent battery removal. Overall, the P5 design exemplifies a well-thought-out approach to robotic motor control, combining various electronic components to achieve a cohesive and functional system.The P5 design uses only eight 74HC/AC240 chips which are all octal inverting buffers. Each 74HC/AC240 chip has two groups of four inverters each controlled by a tri-state enable pin (pin 1 and 19). The 74AC240 chips (U1-U5) are used as H-bridge style motor drivers since they have almost double the drive current compared to 74HC240 chips.

These mot or driver chips are permanently enabled by grounding control pins 1 and 19. The two groups each have four inputs connected in common to a bicore output and the four outputs are connected in common to one motor winding terminal. Since each bicore has two complementary outputs the voltage across the motor winding causes the motor to rotate back and forth.

The 74HC240 chips U6 and U7 are each used to form a master - slave bicore pair with reverser. The inverters used for the bicore s are permanently enabled by grounding pin 1. The inverters used for reversing are turned on or off with the tri-state enable pin 19. Only 2 of the 4 tristate inverters are used conventionally for reversing the phase of the slave bicore s while the other two are put to a novel use: one inverter is used to provide positive feedback to the enable pin and the second spare inverter is used to turn on a RED flashing LED when the reverser is active. The flashing LED also provides diagnostic visual indication of the operation of the slave bicore. The 74HC240 chip used for U8 provides a reverser and a slave bicore for the waist motor as well as a monocore (a.

k. a High Low Oscillator) photobridge comparator which controls the phasing of the front and rear motors. I) The photobridge comparator uses 2 inverter s from U8 connected in series as an voltage controlled oscillator with complementary outputs to generate three states : If the left photodiode gets more light than the right photodiode, the two inverter complementary outputs are steady state DC.

The inverter with the low output reverses the left slave bicore and corresponding rear leg causing the walker to turn left. If the right photodiode gets more light than the left photodiode, the two inverter complementary outputs are steady state DC (opposite to a.

) The inverter with the low output "reverses" the right slave bicore causing the walker to turn right. If both photodiode s get equal light, the two inverter complementary outputs are pulsing and neither of the slave bicore s is reversed causing the walker to go straight.

II) Two master suspended bicore s in U5 and 6 are coupled at their inputs with a 7. 2M phase sync resistor so that they will oscillate in quadrature with their waveforms overlapping by 25%. These waveforms are connected to the 74AC240 motor driver which control the front legs. III) Two rear motor slave bicore s use inverter s from U5 an U6 with timing components that delay the slave bicore output by about 25%.

These are connected to the front leg motor drivers (6 inverters for each motor). IV) Two inverters in U6 and U7 are used for signal reversing and are connected between the outputs of each of the master bicore s (front legs) and the slave bicore s (rear legs) to control turning with enable signals from the photo comparator circuit. When the light is balanced pin 19 of U6 and U7 are both high, both reversers are turned off, the tristate inverter s are disabled and the walker moves straight.

VI) The waist reverser uses two inverter s in U8 and is connected between one output of each of the U6 and U7 master bicore s and the waist slave bicore circuit inputs described in V). The waist motor phase reversal occurs when one of two tactile switches is triggered by collision with an obstacle.

At that time the U8 tristate inverter s are enabled. VII) The power supply consists of a 6V NiCd battery and charger circuit with a three position switch for on-off and charging. A 78L05 is included for recharging a 900mAHr battery pack at 0. 1C without removing it from the walker. The photo compar 🔗 External reference