A Smart Barn Door Drive for Astrophotography

A tracking mount for the Minolta SRT-101 camera. Untracked photos of the Hyakutake comet did not adequately capture its essence due to insufficient exposure times. When a camera is mounted on a sturdy tripod and the shutter is left open for several minutes, the resulting image will show trails, with objects in the frame creating streaks that vary in length according to the exposure duration and the specific area of the sky being photographed. Earth's rotation causes the positions of stars to shift during long exposures, limiting the practical exposure time for a stationary camera to approximately 30 seconds when using a standard wide-angle lens. While extended exposures can have their own artistic value, a drive system is necessary to counteract Earth's rotation and enable longer exposures. An equatorially-driven telescope can provide tracking when a camera is mounted alongside it. For novice astrophotographers seeking a cost-effective solution, a barn door mount serves as a straightforward method for tracking a camera for wide-angle images. The simplest barn door drive consists of two wooden pieces hinged at one end, with one piece affixed to the tripod and a threaded rod extending through the opposite end. This drive screw can be manually adjusted at intervals or powered by a motor to gradually separate the boards. When the hinge axis aligns with the north celestial pole, near Polaris, a camera mounted on the upper board will compensate for Earth's motion, resulting in clear sky images. This basic setup is often referred to as a tangent arm drive, as the drive screw and boards form a right triangle. If the screw is turned at a constant rate, errors can accumulate quickly. A popular variation is the isosceles or single-arm drive, where the screw is pivoted at both ends, forming an isosceles triangle as the boards open. In many designs, the screw is driven at a constant rate using a stepper motor and an oscillator/divider circuit constructed from standard CMOS logic. Some calculations illustrate the relationship between the mount's angular velocity and the drive screw's motion: the angular velocity of the mount (omega) is not constant when the drive screw is turned at a steady rate, leading to constant (dL/dt). Although the approximation for perfect tracking is superior to that of the tangent-arm drive, notable errors can still accumulate after a few minutes. To mitigate tracking errors, a mechanical design using multiple boards and hinges can be employed. If dimensions are correctly chosen, the sine approximation errors in this configuration will largely cancel out. However, this mechanical approach may be less appealing to electrical engineers, as it presents more complexity than circuits and software. A more efficient solution involves varying the speed of the drive screw to counteract errors in the single-arm drive, achievable with a microcontroller, simplifying the electrical construction to a level comparable to classic circuits utilizing SAA-xxxx chips. This design allows the boards to open at a constant angular rate, achieving the desired tracking. Notably, (dL/dt = 2axcos(at)) indicates that perfect tracking occurs when the drive rate decelerates over time. The smart barn door employs a single-arm (isosceles) design, facilitating ease of construction and enabling extended tracking before the screw length is exhausted.

A tracking mount for astrophotography, particularly for cameras like the Minolta SRT-101, is essential for capturing celestial events without the blurring effects caused by Earth's rotation. The barn door mount is a practical and economical solution for amateur astrophotographers, allowing for longer exposures by compensating for the Earth's movement. The design's simplicity, utilizing basic materials and mechanical principles, makes it accessible for users with limited resources.

The fundamental operation of the barn door mount relies on a hinge mechanism that allows two boards to open in an isosceles triangle formation. The drive screw, when turned, adjusts the angle of the boards to maintain alignment with the celestial objects being photographed. This setup requires precise calibration to ensure that the hinge axis is aligned with the north celestial pole, which is critical for effective tracking.

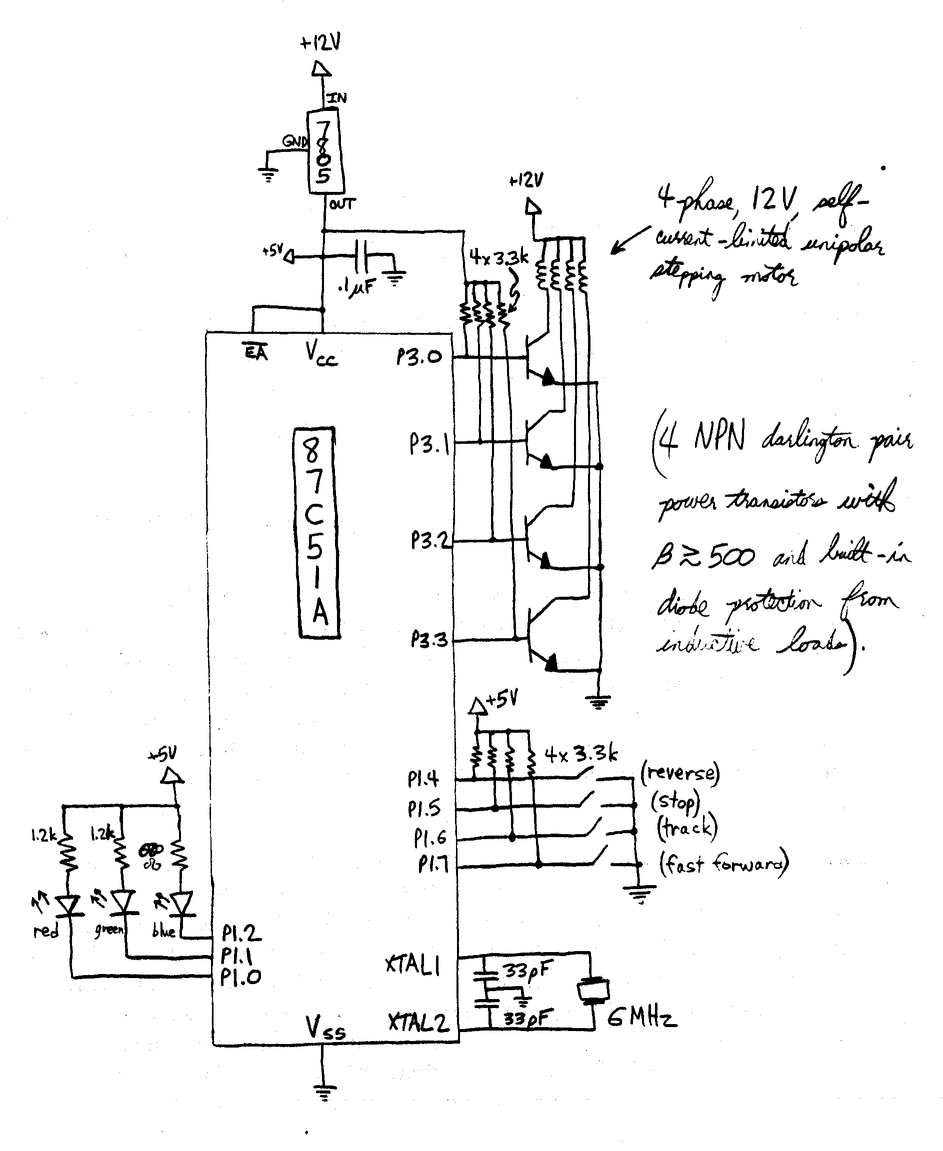

In more advanced configurations, the use of a microcontroller can automate the drive screw's motion, allowing it to adjust the speed dynamically based on the exposure time. This adaptation minimizes tracking errors and enhances the quality of the images captured. The integration of stepper motors and CMOS logic circuits enables precise control over the drive mechanism, facilitating a smoother operation than manual adjustments.

Overall, the barn door mount exemplifies a blend of mechanical ingenuity and electrical engineering, providing a versatile tool for capturing the beauty of the night sky. By addressing the challenges posed by Earth's rotation and optimizing the tracking mechanism, this design significantly enhances the potential for successful astrophotography.A tracking mount for trusty Minolta SRT-101. My untracked photos of Hyakutake had not done the comet justice; the exposures were too short. If one mounts a camera to a sturdy tripod and opens the shutter for several minutes, the developed picture will be trailed, with every object in the frame creating a short or long streak depending on the length of the exposure and the part of the sky being imaged. Because of the Earth`s motion, the positions of the stars shift during any long exposure, thereby limiting the practical exposure time for a fixed camera. This limit works out to around 30 seconds for a normal wide-angle lens. Of course, very long exposures exploiting this effect have their own artistic appeal, but To counteract the Earth`s rotation and allow longer exposures, some kind of drive system is needed.

If an equatorially-driven telescope is available, it can provide the tracking with the camera mounted piggy-back on the side. For beginning astrophotographers seeking a more economical approach, a barn door mount is a simple way to track a camera for wide-angle pictures.

The simplest barn-door drive consists of two pieces of wood, hinged at one end. One piece is mounted to the tripod and has a threaded rod going up through the end opposite the hinge. This drive screw is turned by hand at regular intervals, or driven by a motor, to gradually push the boards apart.

If the hinge axis is aligned with the north celestial pole, very near the star Polaris, a camera riding on the top board will have the Earth`s motion canceled out, resulting in sharp images of the sky. This basic configuration is sometimes called a tangent arm drive, because the drive screw and the boards form a right triangle.

If the screw is turned at a constant rate, errors accumulate rapidly. A popular variation is the isosceles or single-arm drive. Here the screw screw is pivoted at both ends, forming an isosceles triangle as the boards open. In published designs, the screw is almost always driven at a constant rate using a stepper motor and an oscillator/divider circuit built from standard CMOS logic. Some simple math shows how the angular velocity of the mount is related to the motion of the drive screw: In other words, the angular velocity of the mount, omega, will not be constant when the drive screw is turned at a constant rate yielding constant (dL/dt).

The approximation to perfect tracking is much better than the tangent-arm drive, but significant errors will accumulate after a few minutes. To further reduce tracking errors, a mechanical scheme involving multiple boards and hinges has been used[1].

If the dimensions are chosen correctly, the sine approximation errors in this system will mostly cancel out. While interesting, this is not appealing to an electrical engineer. Anything mechanical is hard, or at least harder than circuits and software, so why not take the easy way out and vary the speed of the drive screw, counteracting the errors in the single-arm drive This may be accomplished with a single-chip design (a microcontroller), making the electrical construction no more difficult than the classic circuits designed around SAA-xxxx chips.

and the boards are opening at the hinge at a constant angular rate ” just what we need. Notice that (dL/dt = 2axcos(at)), indicating that perfect tracking is achieved when the drive rate slows down over time. Mechanically, the smart barn door uses a single-arm (isosceles) design, as this is easy to build and can track longer before running out of screw length.

For 🔗 External reference

A tracking mount for astrophotography, particularly for cameras like the Minolta SRT-101, is essential for capturing celestial events without the blurring effects caused by Earth's rotation. The barn door mount is a practical and economical solution for amateur astrophotographers, allowing for longer exposures by compensating for the Earth's movement. The design's simplicity, utilizing basic materials and mechanical principles, makes it accessible for users with limited resources.

The fundamental operation of the barn door mount relies on a hinge mechanism that allows two boards to open in an isosceles triangle formation. The drive screw, when turned, adjusts the angle of the boards to maintain alignment with the celestial objects being photographed. This setup requires precise calibration to ensure that the hinge axis is aligned with the north celestial pole, which is critical for effective tracking.

In more advanced configurations, the use of a microcontroller can automate the drive screw's motion, allowing it to adjust the speed dynamically based on the exposure time. This adaptation minimizes tracking errors and enhances the quality of the images captured. The integration of stepper motors and CMOS logic circuits enables precise control over the drive mechanism, facilitating a smoother operation than manual adjustments.

Overall, the barn door mount exemplifies a blend of mechanical ingenuity and electrical engineering, providing a versatile tool for capturing the beauty of the night sky. By addressing the challenges posed by Earth's rotation and optimizing the tracking mechanism, this design significantly enhances the potential for successful astrophotography.A tracking mount for trusty Minolta SRT-101. My untracked photos of Hyakutake had not done the comet justice; the exposures were too short. If one mounts a camera to a sturdy tripod and opens the shutter for several minutes, the developed picture will be trailed, with every object in the frame creating a short or long streak depending on the length of the exposure and the part of the sky being imaged. Because of the Earth`s motion, the positions of the stars shift during any long exposure, thereby limiting the practical exposure time for a fixed camera. This limit works out to around 30 seconds for a normal wide-angle lens. Of course, very long exposures exploiting this effect have their own artistic appeal, but To counteract the Earth`s rotation and allow longer exposures, some kind of drive system is needed.

If an equatorially-driven telescope is available, it can provide the tracking with the camera mounted piggy-back on the side. For beginning astrophotographers seeking a more economical approach, a barn door mount is a simple way to track a camera for wide-angle pictures.

The simplest barn-door drive consists of two pieces of wood, hinged at one end. One piece is mounted to the tripod and has a threaded rod going up through the end opposite the hinge. This drive screw is turned by hand at regular intervals, or driven by a motor, to gradually push the boards apart.

If the hinge axis is aligned with the north celestial pole, very near the star Polaris, a camera riding on the top board will have the Earth`s motion canceled out, resulting in sharp images of the sky. This basic configuration is sometimes called a tangent arm drive, because the drive screw and the boards form a right triangle.

If the screw is turned at a constant rate, errors accumulate rapidly. A popular variation is the isosceles or single-arm drive. Here the screw screw is pivoted at both ends, forming an isosceles triangle as the boards open. In published designs, the screw is almost always driven at a constant rate using a stepper motor and an oscillator/divider circuit built from standard CMOS logic. Some simple math shows how the angular velocity of the mount is related to the motion of the drive screw: In other words, the angular velocity of the mount, omega, will not be constant when the drive screw is turned at a constant rate yielding constant (dL/dt).

The approximation to perfect tracking is much better than the tangent-arm drive, but significant errors will accumulate after a few minutes. To further reduce tracking errors, a mechanical scheme involving multiple boards and hinges has been used[1].

If the dimensions are chosen correctly, the sine approximation errors in this system will mostly cancel out. While interesting, this is not appealing to an electrical engineer. Anything mechanical is hard, or at least harder than circuits and software, so why not take the easy way out and vary the speed of the drive screw, counteracting the errors in the single-arm drive This may be accomplished with a single-chip design (a microcontroller), making the electrical construction no more difficult than the classic circuits designed around SAA-xxxx chips.

and the boards are opening at the hinge at a constant angular rate ” just what we need. Notice that (dL/dt = 2axcos(at)), indicating that perfect tracking is achieved when the drive rate slows down over time. Mechanically, the smart barn door uses a single-arm (isosceles) design, as this is easy to build and can track longer before running out of screw length.

For 🔗 External reference