AC arc welding machine transistor load power path from 2

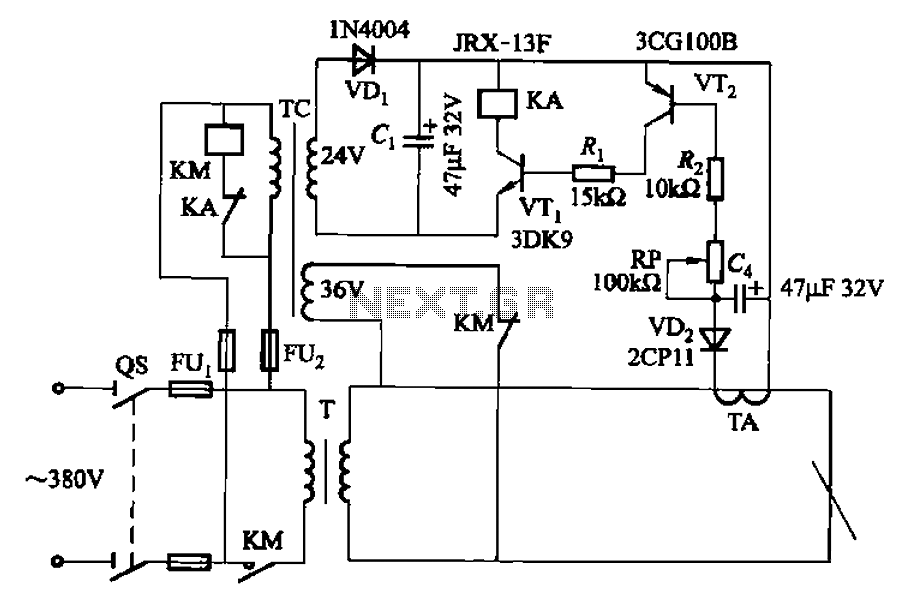

The AC arc welding machine's transistor load path for the power from the second circuit is illustrated. The figure shows a current transformer with a core cross-section of 25 mm². The transformer has a primary winding with a certain number of turns and a secondary winding with 1000 turns. The contactor selected for this application is a CJ20-40A rated for 380V.

The AC arc welding machine operates by converting electrical energy into an arc that melts the workpiece material for welding. In this circuitry, the power path is crucial for efficient operation and reliability. The current transformer (TA) plays a significant role in monitoring and controlling the current flowing through the welding circuit. The specified core cross-section of 25 mm² indicates the size of the core, which is essential for minimizing losses and ensuring adequate magnetic coupling between the primary and secondary windings.

The primary winding is designed to have a specific number of turns, which are not detailed in the provided data but are necessary for establishing the correct turns ratio with the secondary winding. The secondary winding consists of 1000 turns, which allows for the appropriate voltage transformation needed for the welding process. This high turns ratio is indicative of the transformer’s role in stepping down the voltage while increasing the current, which is essential for generating the intense heat required for arc welding.

The contactor (KA) selected for this system is a CJ20-40A model rated for 380V. This component is crucial for switching the power to the welding machine on and off, ensuring safe operation. The contactor must be capable of handling the high inrush currents typically associated with welding applications. The choice of a 40A rating provides a safety margin to accommodate potential surges in current during operation.

Overall, the described circuit components—current transformer and contactor—are integral to the performance and safety of the AC arc welding machine, ensuring effective operation while managing the electrical load efficiently.AC arc welding machine transistor load path of the power from the second circuit is shown. The figure, the current transformer TA core cross-section 25rrirr12, as l primary tur ns to secondary turns 1000. Contactor KA selection CJ20-40A, 380V.

The AC arc welding machine operates by converting electrical energy into an arc that melts the workpiece material for welding. In this circuitry, the power path is crucial for efficient operation and reliability. The current transformer (TA) plays a significant role in monitoring and controlling the current flowing through the welding circuit. The specified core cross-section of 25 mm² indicates the size of the core, which is essential for minimizing losses and ensuring adequate magnetic coupling between the primary and secondary windings.

The primary winding is designed to have a specific number of turns, which are not detailed in the provided data but are necessary for establishing the correct turns ratio with the secondary winding. The secondary winding consists of 1000 turns, which allows for the appropriate voltage transformation needed for the welding process. This high turns ratio is indicative of the transformer’s role in stepping down the voltage while increasing the current, which is essential for generating the intense heat required for arc welding.

The contactor (KA) selected for this system is a CJ20-40A model rated for 380V. This component is crucial for switching the power to the welding machine on and off, ensuring safe operation. The contactor must be capable of handling the high inrush currents typically associated with welding applications. The choice of a 40A rating provides a safety margin to accommodate potential surges in current during operation.

Overall, the described circuit components—current transformer and contactor—are integral to the performance and safety of the AC arc welding machine, ensuring effective operation while managing the electrical load efficiently.AC arc welding machine transistor load path of the power from the second circuit is shown. The figure, the current transformer TA core cross-section 25rrirr12, as l primary tur ns to secondary turns 1000. Contactor KA selection CJ20-40A, 380V.