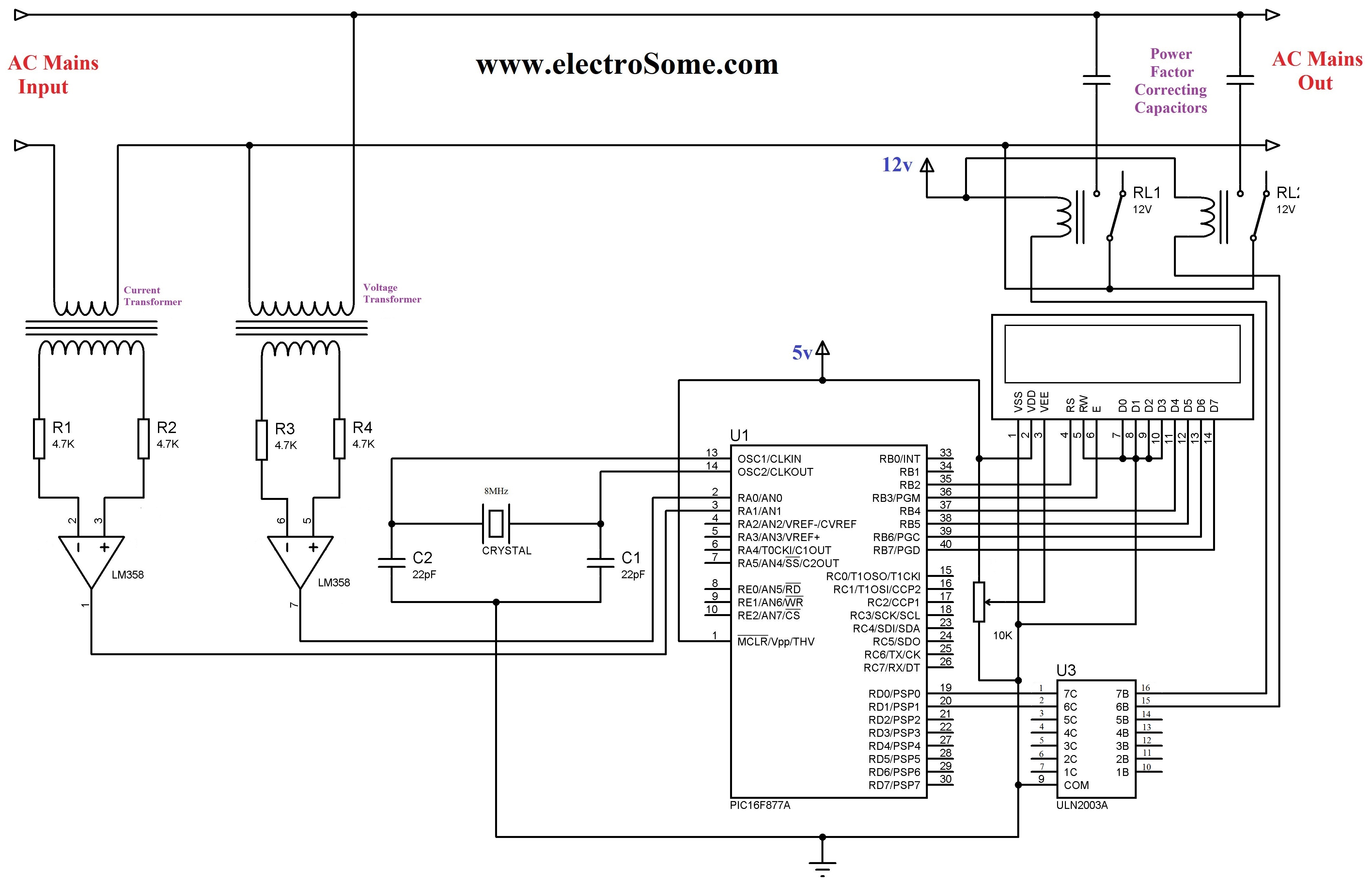

automatic power factor controller using microcontroller

The 230 V, 50 Hz supply is stepped down using a voltage transformer, while a current transformer is utilized to extract the current waveforms. The output of the voltage transformer corresponds to the voltage across the load, and the output of the current transformer is proportional to the current flowing through the load. These waveforms are fed to voltage comparators constructed using the LM358 op-amp. As a zero-crossing detector, its output changes during the zero crossing of the current and voltage waveforms. These outputs are then sent to the PIC microcontroller, which performs further power factor calculations. The PIC 16F877A microcontroller serves as the core of this Automatic Power Factor Controller, determining, displaying, and controlling the power factor. To correct the power factor, the current power factor is first calculated by taking the tangent of the ratio of the time between the zero crossings of the current and voltage waveforms and the time between two successive zero crossings of the voltage waveform. The calculated power factor is displayed on a 16x2 LCD display, and capacitors are switched on if needed. When a load is connected, the power factor is calculated by the PIC microcontroller. If the calculated power factor is less than 0.9, the relay activates the capacitor. The relays are driven by the ULN2003, a driver IC that consists of seven Darlington pairs. The leading current in the capacitor compensates for the lagging current typically present in inductive loads, thereby reducing the phase difference between the current and voltage. The power factor correcting capacitor is connected in parallel with the load through a relay. If the relay is energized by the microcontroller, the capacitor is connected in parallel with the load; if the relay is de-energized, the capacitor is removed from the load. When a resistive load is present, the power factor approaches unity, and the microcontroller does not energize the relay coil. Conversely, when an inductive load is present, the power factor decreases, prompting the microcontroller to energize the relay coil to compensate for the excessive reactive power. This ensures that the power factor is corrected according to the load conditions.

The LCD module connections are established as follows: the RS pin is connected to RB4, the EN pin to RB5, and data pins D4 to D7 are connected to RB0 to RB3 respectively. The direction of these pins is defined in the code, ensuring proper communication between the microcontroller and the LCD.

The function `powerFactor()` calculates the current power factor using the Timer 1 module of the PIC 16F877A. The algorithm captures the time intervals between zero crossings of the current and voltage waveforms, calculating the power factor based on these measurements. The main program continuously reads the power factor, averaging multiple readings to mitigate fluctuations. It displays the power factor on the LCD and controls the relay based on the calculated value, ensuring the power factor remains within acceptable limits for efficient operation.

The implementation utilizes various configurations of the microcontroller's ports to manage input and output effectively, ensuring a robust design for automatic power factor correction in real-time applications.The 230 V, 50 Hz is step downed using voltage transformer and current transformer is used to extract the waveforms of current. The output of the voltage transformer is proportional to the voltage across the load and output of current transformer is proportional to the currentG‚throughG‚the load.

These waveforms are fed to Voltage Comparators const ructedG‚usingG‚LM358G‚op-amp. Since it is a zero crossing detector, its outputG‚changesG‚during zero crossing of the current and voltage waveforms. These outputs are fed to the PIC which does the further power factor calculations. PIC 16F877A microcontroller is the heart of this Automatic Power Factor Controller, it find, displays andG‚controlsG‚the Power Factor.

To correct power factor, first we need to find the current power factor. It can be find by taking tangent of ratio of time between zero crossing of current and voltageG‚waveformsG‚and two successive zero crossing of voltage waveform. Then it displays the calculated power factor in the 16G—2 LCD Display andG‚switchesG‚ON the capacitors if required.

When load is connected the power factor is calculated by the PIC microcontroller. If the calculated power factor is less than 0. 9 then the relay switches on the capacitor. The relays are switched using ULN2003 which is basically a driver IC. ULN2003 consists of seven DARLINGTON PAIRS. The current lead in capacitor compensates the corresponding current lag which is usually present in loads. Hence the phase difference between the current and voltage will be reduced. Power Factor Correcting capacitor connected parallel to load through relay, if the relay is energized by microcontroller it will connect G‚the capacitor parallel with load, if relay deenergized it will remove the capacitor from the load.

When the resistive load is on the power factor will be near to unity so the microcontrollerG‚doesn`tG‚energize the relay coil. When the inductive load is on the power factor decrease now the microcontroller energize the relay coil in order to compensate the excessive reactive power.

Hence according to the load the power factor is corrected. //LCD Module Connections sbit LCD_RS at RB4_bit; sbit LCD_EN at RB5_bit; sbit LCD_D4 at RB0_bit; sbit LCD_D5 at RB1_bit; sbit LCD_D6 at RB2_bit; sbit LCD_D7 at RB3_bit; sbit LCD_RS_Direction at TRISB4_bit; sbit LCD_EN_Direction at TRISB5_bit; sbit LCD_D4_Direction at TRISB0_bit; sbit LCD_D5_Direction at TRISB1_bit; sbit LCD_D6_Direction at TRISB2_bit; sbit LCD_D7_Direction at TRISB3_bit; //End LCD Module Connections int powerFactor() { int a=0, b=0, t=0, x=0; float tm, pf; TMR1L=0; TMR1H=0; do { if(PORTA. F0 = 1) T1CON. F0 = 1; else if(PORTA. F0 = 0 && T1CON. F0 = 1) { T1CON. F0 = 0; break; } }while(1); a = (TMR1L | (TMR1H<<8) * 2; TMR1L=0; TMR1H=0; do { if(PORTA. F0 = 1) { T1CON. F0=1; if(PORTA. F1=1) { T1CON. F0=0; break; } } }while(1); b = TMR1L | (TMR1H<<8); tm = (float)b/a; pf = cos(tm*2*3. 14); x=abs(ceil(pf*100); return x; } void main() { char c[]="0. 00"; int a, b, d, x, f, e; float tm, pf; Lcd_Init(); Lcd_Cmd(_LCD_CURSOR_OFF); // Cursor off ADCON1 = 0x08; // To configure PORTA pins as digital TRISA.

F0 = 1; // Makes First pin of PORTA as input TRISA. F1 = 1; //Makes Second pin of PORTA as input TRISD. F0 = 0; //Makes Fist pin of PORTD as output TRISD. F1 = 0; //Makes Second pin of PORTD as output while(1) { a = powerFactor(); Delay_us(50); b = powerFactor(); Delay_us(50); d = powerFactor(); Delay_us(50); e = powerFactor(); Delay_us(50); f = powerFactor(); x = (a+b+d+f+e)/5; c[3]=x%10 + 0x30; x=x/10; c[2]=x%10 + 0x30; x=x/10; c[0]=x%10 + 0x30; Lcd_Out(1, 1, "Power Factor"); Lcd_Out(2, 1, c); if(x<90) { PORTD. F0 = 1; PORTD. F0 = 1; Delay_ms(2000); } else { PORTD. F0 = 0; PORTD. F0 = 0; } Delay_ms(250); } } The function powerFactor() will find the current power factor by using the Timer 1 module of PIC 16F877a.

Power Factor may be fluctuating, so to avoid it we will find power facto 🔗 External reference

The LCD module connections are established as follows: the RS pin is connected to RB4, the EN pin to RB5, and data pins D4 to D7 are connected to RB0 to RB3 respectively. The direction of these pins is defined in the code, ensuring proper communication between the microcontroller and the LCD.

The function `powerFactor()` calculates the current power factor using the Timer 1 module of the PIC 16F877A. The algorithm captures the time intervals between zero crossings of the current and voltage waveforms, calculating the power factor based on these measurements. The main program continuously reads the power factor, averaging multiple readings to mitigate fluctuations. It displays the power factor on the LCD and controls the relay based on the calculated value, ensuring the power factor remains within acceptable limits for efficient operation.

The implementation utilizes various configurations of the microcontroller's ports to manage input and output effectively, ensuring a robust design for automatic power factor correction in real-time applications.The 230 V, 50 Hz is step downed using voltage transformer and current transformer is used to extract the waveforms of current. The output of the voltage transformer is proportional to the voltage across the load and output of current transformer is proportional to the currentG‚throughG‚the load.

These waveforms are fed to Voltage Comparators const ructedG‚usingG‚LM358G‚op-amp. Since it is a zero crossing detector, its outputG‚changesG‚during zero crossing of the current and voltage waveforms. These outputs are fed to the PIC which does the further power factor calculations. PIC 16F877A microcontroller is the heart of this Automatic Power Factor Controller, it find, displays andG‚controlsG‚the Power Factor.

To correct power factor, first we need to find the current power factor. It can be find by taking tangent of ratio of time between zero crossing of current and voltageG‚waveformsG‚and two successive zero crossing of voltage waveform. Then it displays the calculated power factor in the 16G—2 LCD Display andG‚switchesG‚ON the capacitors if required.

When load is connected the power factor is calculated by the PIC microcontroller. If the calculated power factor is less than 0. 9 then the relay switches on the capacitor. The relays are switched using ULN2003 which is basically a driver IC. ULN2003 consists of seven DARLINGTON PAIRS. The current lead in capacitor compensates the corresponding current lag which is usually present in loads. Hence the phase difference between the current and voltage will be reduced. Power Factor Correcting capacitor connected parallel to load through relay, if the relay is energized by microcontroller it will connect G‚the capacitor parallel with load, if relay deenergized it will remove the capacitor from the load.

When the resistive load is on the power factor will be near to unity so the microcontrollerG‚doesn`tG‚energize the relay coil. When the inductive load is on the power factor decrease now the microcontroller energize the relay coil in order to compensate the excessive reactive power.

Hence according to the load the power factor is corrected. //LCD Module Connections sbit LCD_RS at RB4_bit; sbit LCD_EN at RB5_bit; sbit LCD_D4 at RB0_bit; sbit LCD_D5 at RB1_bit; sbit LCD_D6 at RB2_bit; sbit LCD_D7 at RB3_bit; sbit LCD_RS_Direction at TRISB4_bit; sbit LCD_EN_Direction at TRISB5_bit; sbit LCD_D4_Direction at TRISB0_bit; sbit LCD_D5_Direction at TRISB1_bit; sbit LCD_D6_Direction at TRISB2_bit; sbit LCD_D7_Direction at TRISB3_bit; //End LCD Module Connections int powerFactor() { int a=0, b=0, t=0, x=0; float tm, pf; TMR1L=0; TMR1H=0; do { if(PORTA. F0 = 1) T1CON. F0 = 1; else if(PORTA. F0 = 0 && T1CON. F0 = 1) { T1CON. F0 = 0; break; } }while(1); a = (TMR1L | (TMR1H<<8) * 2; TMR1L=0; TMR1H=0; do { if(PORTA. F0 = 1) { T1CON. F0=1; if(PORTA. F1=1) { T1CON. F0=0; break; } } }while(1); b = TMR1L | (TMR1H<<8); tm = (float)b/a; pf = cos(tm*2*3. 14); x=abs(ceil(pf*100); return x; } void main() { char c[]="0. 00"; int a, b, d, x, f, e; float tm, pf; Lcd_Init(); Lcd_Cmd(_LCD_CURSOR_OFF); // Cursor off ADCON1 = 0x08; // To configure PORTA pins as digital TRISA.

F0 = 1; // Makes First pin of PORTA as input TRISA. F1 = 1; //Makes Second pin of PORTA as input TRISD. F0 = 0; //Makes Fist pin of PORTD as output TRISD. F1 = 0; //Makes Second pin of PORTD as output while(1) { a = powerFactor(); Delay_us(50); b = powerFactor(); Delay_us(50); d = powerFactor(); Delay_us(50); e = powerFactor(); Delay_us(50); f = powerFactor(); x = (a+b+d+f+e)/5; c[3]=x%10 + 0x30; x=x/10; c[2]=x%10 + 0x30; x=x/10; c[0]=x%10 + 0x30; Lcd_Out(1, 1, "Power Factor"); Lcd_Out(2, 1, c); if(x<90) { PORTD. F0 = 1; PORTD. F0 = 1; Delay_ms(2000); } else { PORTD. F0 = 0; PORTD. F0 = 0; } Delay_ms(250); } } The function powerFactor() will find the current power factor by using the Timer 1 module of PIC 16F877a.

Power Factor may be fluctuating, so to avoid it we will find power facto 🔗 External reference