Automatic Water Tank Filler Circuit

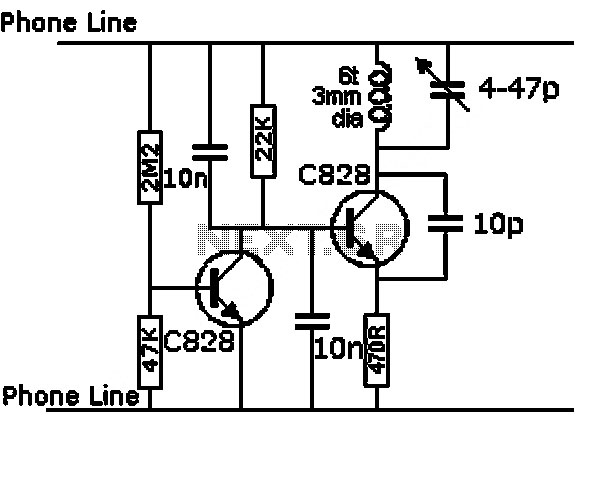

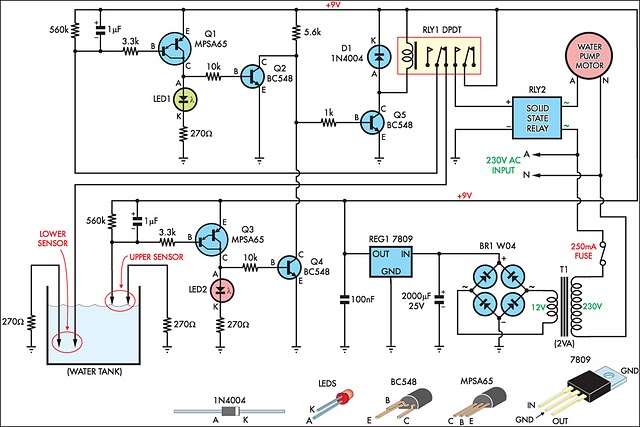

This circuit is designed to effectively fill a header tank for a reticulated water supply on a farm. It supports eight troughs located in various paddocks, where inadequate water supply can have serious repercussions for livestock. Previously, a timer-based system was employed to fill the tank daily, but it proved ineffective. During hot weather, the livestock would deplete the tank regularly, leaving them without water for several hours. Conversely, during wet weather, the tank would overflow if the cattle did not consume much water. The circuit maintains the water level in the header tank within specified limits. It controls a 3HP submersible bore pump, which requires a solid-state relay capable of handling the high starting current. Two Darlington transistors, Q1 and Q3, along with Q2 and Q4, are connected to the upper and lower water sensors in the tank. Q2 and Q4 share a common 5.6 kΩ load resistor and function as a NOR gate. The output from the NOR gate drives Q5, which activates relay RLY1. When the water level is low, both sensors are open-circuit, resulting in a high output from the NOR gate that turns on the relay. This action opens the normally closed (NC) contacts of the relay, disconnecting the lower sensor. However, since the upper sensor remains open-circuit, the NOR gate output stays high, keeping the relay engaged. The normally open (NO) contact of the relay closes to activate the solid-state relay RLY2, which runs the pump. This condition persists until the water level reaches the upper sensor, causing the NOR gate output to drop to 0V, disabling relay RLY1 and stopping the pump. The upper level sensor is positioned just below the tank's overflow, while the lower sensor is located about halfway up the tank. The sensor contacts consist of two stainless steel screws spaced approximately 25mm apart, which are mounted through the poly tank walls. The wiring junctions on the tank's side are sealed with neutral-cure silicone sealant for protection.

The circuit's design is crucial for ensuring a reliable water supply to livestock, particularly in environments where water levels fluctuate due to varying consumption patterns. The use of Darlington transistors allows for efficient switching, providing the necessary amplification to control the relay and pump system. The NOR gate configuration simplifies the logic required to manage the two sensors, ensuring that the pump operates only when needed. The choice of a solid-state relay for the pump control enhances durability and responsiveness, particularly under high inrush current conditions.

The sensors, constructed from stainless steel, are resistant to corrosion and can withstand the harsh environment typically found in agricultural settings. The careful placement of the sensors ensures that the system responds promptly to changes in water levels, preventing both overfilling and dry conditions that could jeopardize livestock health. The protective sealant used at the wiring junctions further enhances the reliability of the installation, safeguarding against moisture ingress that could lead to short circuits or failures.

Overall, this circuit exemplifies an effective solution for automated water management in agricultural applications, combining robust components and a straightforward control logic to maintain optimal water levels in the header tank.This circuit has been very useful in filling a header tank for a reticulated water supply on a farm. Eight troughs are supplied in different paddocks where a lack of water would have serious consequences for the stock. In the past, the tank had been filled daily by a time clock which was not successful. During hot weather, the stock would empty th e tank on a regular basis and then be without water for several hours or the tank would overflow and flood the area if the weather was wet and the cattle did not drink much. The circuit described has been used to maintain the level of water in the header tank within prescribed limits.

It controls a 3HP submersible bore pump which has a high starting current, necessitating a solid-state relay sufficient to take the starting load. Two Darlington transistors, Q1 & Q3, in conjunction with Q2 & Q4, are connected to the upper and lower water sensors in the tank.

Q2 & Q4 have a common 5. 6kO load resistor and function as a NOR gate. The output of the NOR gate drives Q5 which activates relay RLY1. Initially, when the water level is low, both sensors will be open-circuit, the NOR gate output will be high and the relay will be turned on. This causes the normally closed (NC) contacts of the relay to open and disconnect the lower sensor. However, the upper sensor will still be open circuit and the NOR gate output will be high, keeping the relay closed.

The normally open (NO) contact of the relay will be closed to operate the solid-state relay RLY2 to run the pump. This state continues until the water reaches the top sensor which will then drop the output from the NOR gate to 0V.

The disables relay RLY1 and the pump is stopped. In practice the upper level sensor is just below the overflow from the tank and the lower sensor about half way up the tank. The sensor contacts are simply two stainless steel screws about 25mm apart and screwed through the poly tank walls.

The wiring junctions on the side of the tank are protected by neutral-cure silicone sealant. 🔗 External reference

The circuit's design is crucial for ensuring a reliable water supply to livestock, particularly in environments where water levels fluctuate due to varying consumption patterns. The use of Darlington transistors allows for efficient switching, providing the necessary amplification to control the relay and pump system. The NOR gate configuration simplifies the logic required to manage the two sensors, ensuring that the pump operates only when needed. The choice of a solid-state relay for the pump control enhances durability and responsiveness, particularly under high inrush current conditions.

The sensors, constructed from stainless steel, are resistant to corrosion and can withstand the harsh environment typically found in agricultural settings. The careful placement of the sensors ensures that the system responds promptly to changes in water levels, preventing both overfilling and dry conditions that could jeopardize livestock health. The protective sealant used at the wiring junctions further enhances the reliability of the installation, safeguarding against moisture ingress that could lead to short circuits or failures.

Overall, this circuit exemplifies an effective solution for automated water management in agricultural applications, combining robust components and a straightforward control logic to maintain optimal water levels in the header tank.This circuit has been very useful in filling a header tank for a reticulated water supply on a farm. Eight troughs are supplied in different paddocks where a lack of water would have serious consequences for the stock. In the past, the tank had been filled daily by a time clock which was not successful. During hot weather, the stock would empty th e tank on a regular basis and then be without water for several hours or the tank would overflow and flood the area if the weather was wet and the cattle did not drink much. The circuit described has been used to maintain the level of water in the header tank within prescribed limits.

It controls a 3HP submersible bore pump which has a high starting current, necessitating a solid-state relay sufficient to take the starting load. Two Darlington transistors, Q1 & Q3, in conjunction with Q2 & Q4, are connected to the upper and lower water sensors in the tank.

Q2 & Q4 have a common 5. 6kO load resistor and function as a NOR gate. The output of the NOR gate drives Q5 which activates relay RLY1. Initially, when the water level is low, both sensors will be open-circuit, the NOR gate output will be high and the relay will be turned on. This causes the normally closed (NC) contacts of the relay to open and disconnect the lower sensor. However, the upper sensor will still be open circuit and the NOR gate output will be high, keeping the relay closed.

The normally open (NO) contact of the relay will be closed to operate the solid-state relay RLY2 to run the pump. This state continues until the water reaches the top sensor which will then drop the output from the NOR gate to 0V.

The disables relay RLY1 and the pump is stopped. In practice the upper level sensor is just below the overflow from the tank and the lower sensor about half way up the tank. The sensor contacts are simply two stainless steel screws about 25mm apart and screwed through the poly tank walls.

The wiring junctions on the side of the tank are protected by neutral-cure silicone sealant. 🔗 External reference