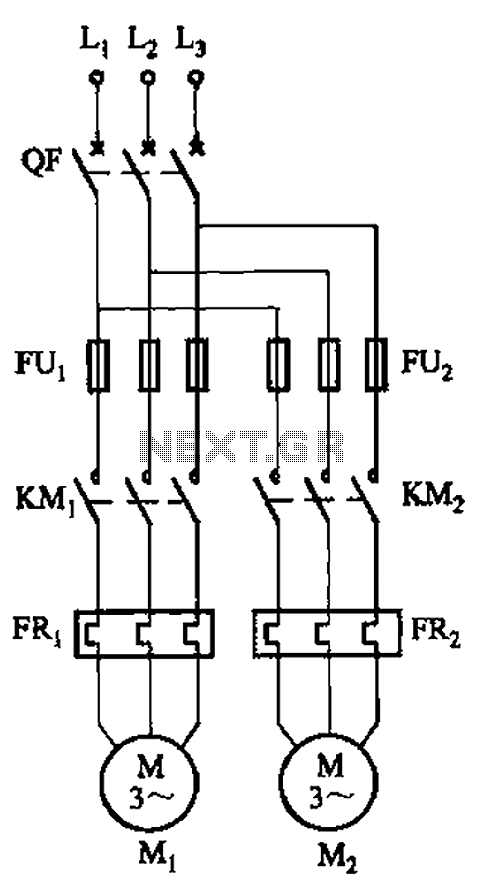

The use of a motor control switch automatic circuit a mutual investment

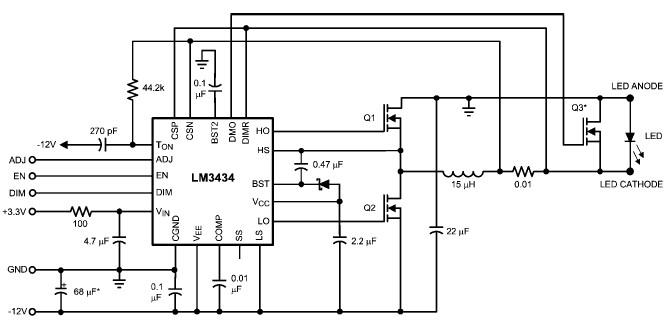

The circuit illustrated in Figure 3-64 operates with switch SA1 in the work position and switch SA2 in the standby position, allowing motor Mi to run while motor Mz remains on standby. In the event of downtime for motor Mi, motor Mz is automatically activated. Conversely, when switch SA2 is in the work position and switch SA1 is in standby, motor M2 operates while motor Mi remains on standby. If motor M2 experiences downtime, motor Mi is automatically activated. Additionally, when both switches SA1 and SA2 are set to the manual position, motors Mi and M2 can be controlled independently. The switches SA1 and SA2 are of the type LW5-15D0404/2 transfer switch.

The circuit described operates through a series of interlocked switches that facilitate automatic and manual control of two motors, Mi and M2. In the automatic mode, the system ensures that when one motor is running, the other is on standby, thus providing redundancy and reliability. The configuration allows for seamless operation; if the primary motor fails or requires maintenance, the secondary motor can take over without manual intervention, minimizing downtime.

The specific switches utilized, LW5-15D0404/2, are designed for durability and reliability in industrial applications, ensuring that the circuit can handle the operational demands placed upon it. The manual control feature adds flexibility, allowing operators to start or stop each motor independently based on operational requirements. This capability is particularly useful in scenarios where one motor may need to be serviced while the other continues to operate.

The design of the circuit emphasizes safety and efficiency. By incorporating automatic transfer capabilities, it reduces the risk of system failure due to motor downtime. The interlock mechanism prevents both motors from running simultaneously, which could lead to overload conditions. Overall, this circuit design is well-suited for applications requiring high availability and operational flexibility in motor control. Circuit shown in Figure 3-64. When the switch SAi placed in the work position, SA2 placed in the standby position, the motor is running Mi, Mz spare. When downtime occurs when Mi, Mz automatically put into operation; similarly, SAz into work position, SAi placed in the standby position, the M2 run, Mi spare, when downtime occurs when M2, Mi automatically put into operation. When SAi and SA2 are placed in the manual position, you can separately Mi, M2 motor manual control. SAi and SA2 can type LW5-15D0404/2 transfer switch.

The circuit described operates through a series of interlocked switches that facilitate automatic and manual control of two motors, Mi and M2. In the automatic mode, the system ensures that when one motor is running, the other is on standby, thus providing redundancy and reliability. The configuration allows for seamless operation; if the primary motor fails or requires maintenance, the secondary motor can take over without manual intervention, minimizing downtime.

The specific switches utilized, LW5-15D0404/2, are designed for durability and reliability in industrial applications, ensuring that the circuit can handle the operational demands placed upon it. The manual control feature adds flexibility, allowing operators to start or stop each motor independently based on operational requirements. This capability is particularly useful in scenarios where one motor may need to be serviced while the other continues to operate.

The design of the circuit emphasizes safety and efficiency. By incorporating automatic transfer capabilities, it reduces the risk of system failure due to motor downtime. The interlock mechanism prevents both motors from running simultaneously, which could lead to overload conditions. Overall, this circuit design is well-suited for applications requiring high availability and operational flexibility in motor control. Circuit shown in Figure 3-64. When the switch SAi placed in the work position, SA2 placed in the standby position, the motor is running Mi, Mz spare. When downtime occurs when Mi, Mz automatically put into operation; similarly, SAz into work position, SAi placed in the standby position, the M2 run, Mi spare, when downtime occurs when M2, Mi automatically put into operation. When SAi and SA2 are placed in the manual position, you can separately Mi, M2 motor manual control. SAi and SA2 can type LW5-15D0404/2 transfer switch.