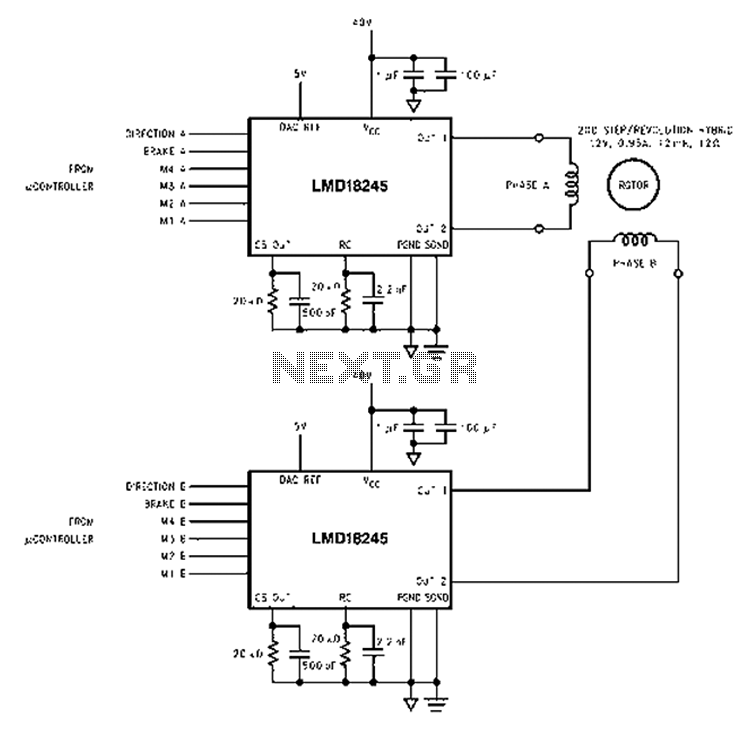

Based LMD18245 bipolar stepper motor control circuit diagram

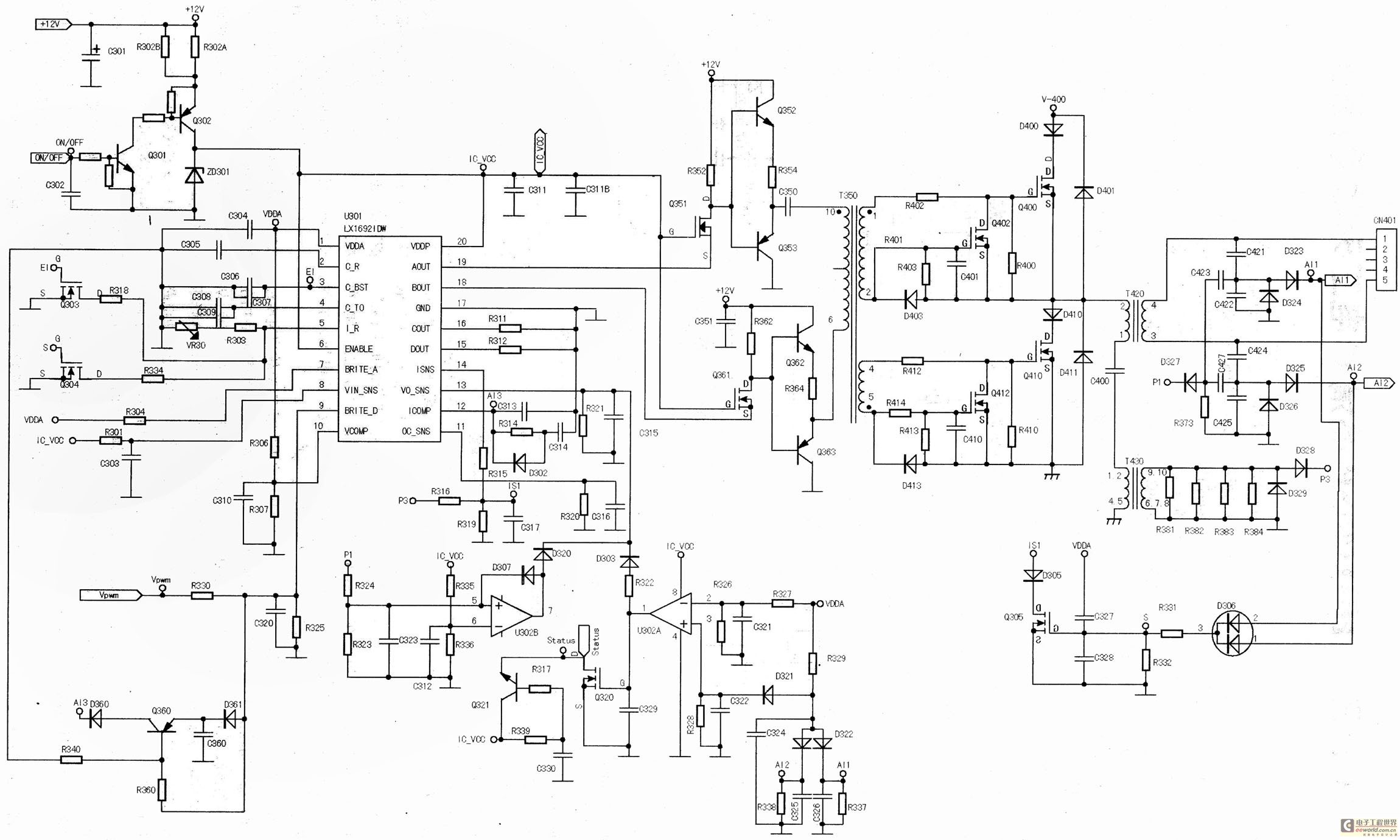

An innovative current detection method eliminates the power loss associated with the sense resistor in series with the motor. A 4-digit analog converter (DAC) facilitates digital control of the motor current path, simplifying the implementation of full, half, and micro-stepping motor drivers. The LMD18245 application circuit serves as a bipolar chopper drive stepper motor power stage. A 20 kΩ resistor and a 2.2 nF capacitor are connected between the RC, setting an off-time of approximately 48 microseconds. The 20 kΩ resistor is also connected to the output and ground, establishing a threshold of about 200 milliamperes per volt gain in the chopper current sense (CS). The LMD18245 can control DC brush motors and bipolar stepper motors, allowing the design of circuits suitable for various motor control applications. The LMD18245 utilizes a fixed off-time chopper technique, with all DMOS H-bridge power stages capable of delivering up to 3 A of continuous output current (6 A peak) at supply voltages up to 55 V. The DMOS power switch features low RDS(ON) resistance, and its internal body diode eliminates the need for a discrete diode clamp in a bipolar power stage. The innovative current detection method further reduces power loss in the system, while the 4-digit DAC enhances the digital control of motor current paths, facilitating various drive types, such as full step and half step, with control signals typically provided by a digital processor controller.

The LMD18245 integrated circuit is designed to efficiently manage motor control applications by utilizing advanced techniques to minimize power loss and optimize performance. The implementation of a fixed off-time chopper strategy allows for precise control of the motor current, ensuring that the motor operates within its specified parameters. The choice of a 20 kΩ resistor in conjunction with a 2.2 nF capacitor is critical for establishing the timing characteristics of the chopper operation, directly influencing the off-time duration and, consequently, the motor's performance.

The capability of the LMD18245 to support both DC brush motors and bipolar stepper motors broadens its application range, making it suitable for various automation and robotics projects. The integration of a DMOS H-bridge power stage not only enhances the output current capacity but also improves thermal management, as the low RDS(ON) reduces power dissipation during operation.

Furthermore, the internal body diode of the DMOS structure simplifies the design by removing the need for additional discrete components, which can complicate the circuit layout and increase the overall size of the motor driver. The digital control aspect, facilitated by the 4-digit DAC, allows for seamless integration with microcontrollers or digital signal processors, enabling sophisticated control algorithms that can adapt to different operational modes such as full step, half step, and micro-stepping.

In conclusion, the LMD18245 bipolar chopper drive stepper motor power stage represents a significant advancement in motor control technology, combining efficiency, flexibility, and ease of use in a compact solution suitable for a broad range of applications.An innovative current detection method, eliminating the power loss of the sense resistor in series with the motor, a 4-digit - analog converter (DAC), provides a digital contro l motor current path, and, by extension, to simplify the implementation of full, half and micro step motor driver, which LMD18245 the application circuit is a bipolar chopper drive stepper motor power stage. 20k resistor and 2.2 nF capacitor connected between the RC and set off time of about 48 microseconds, 20k resistor connected to the output and ground about 200 milliamperes per volt threshold is set to gain in the chopper CS.

Use LMD18245 full-bridge power amplifier integrated DC brush motor bipolar stepper motor or a stage, all of the circuit can be designed to block the application of a variety of motor control and current drive needed. LMD18245 motor control current through a fixed off-time chopper technique, all DMOS H-bridge power stage delivers up to 3A of continuous output current (6A peak) at supply voltages up to 55V DMOS power switch is an efficient low RDS ( ON), and a diode internal DMOS body structure, eliminating the typically required discrete diode clamp bipolar power stage.

An innovative current detection method, eliminating the power loss of the sense resistor in series with the motor, a 4-digit - analog converter (DAC), provides a digital control motor current path, and, by extension, to simplify the implementation of full, half and micro step motor driver application circuit LMD18245 this is a bipolar chopper drive stepper motor power stage. 20k resistor and 2.2 nF capacitor connected between the RC and set off time of about 48 microseconds, 20k resistor connected to the output and ground about 200 milliamperes per volt threshold is set to gain in the chopper CS.

Direction for digital signal control chopped threshold, winding current, by extension, drive type (full step, half step, and so on). Or a digital processor controller usually provide control signals.

The LMD18245 integrated circuit is designed to efficiently manage motor control applications by utilizing advanced techniques to minimize power loss and optimize performance. The implementation of a fixed off-time chopper strategy allows for precise control of the motor current, ensuring that the motor operates within its specified parameters. The choice of a 20 kΩ resistor in conjunction with a 2.2 nF capacitor is critical for establishing the timing characteristics of the chopper operation, directly influencing the off-time duration and, consequently, the motor's performance.

The capability of the LMD18245 to support both DC brush motors and bipolar stepper motors broadens its application range, making it suitable for various automation and robotics projects. The integration of a DMOS H-bridge power stage not only enhances the output current capacity but also improves thermal management, as the low RDS(ON) reduces power dissipation during operation.

Furthermore, the internal body diode of the DMOS structure simplifies the design by removing the need for additional discrete components, which can complicate the circuit layout and increase the overall size of the motor driver. The digital control aspect, facilitated by the 4-digit DAC, allows for seamless integration with microcontrollers or digital signal processors, enabling sophisticated control algorithms that can adapt to different operational modes such as full step, half step, and micro-stepping.

In conclusion, the LMD18245 bipolar chopper drive stepper motor power stage represents a significant advancement in motor control technology, combining efficiency, flexibility, and ease of use in a compact solution suitable for a broad range of applications.An innovative current detection method, eliminating the power loss of the sense resistor in series with the motor, a 4-digit - analog converter (DAC), provides a digital contro l motor current path, and, by extension, to simplify the implementation of full, half and micro step motor driver, which LMD18245 the application circuit is a bipolar chopper drive stepper motor power stage. 20k resistor and 2.2 nF capacitor connected between the RC and set off time of about 48 microseconds, 20k resistor connected to the output and ground about 200 milliamperes per volt threshold is set to gain in the chopper CS.

Use LMD18245 full-bridge power amplifier integrated DC brush motor bipolar stepper motor or a stage, all of the circuit can be designed to block the application of a variety of motor control and current drive needed. LMD18245 motor control current through a fixed off-time chopper technique, all DMOS H-bridge power stage delivers up to 3A of continuous output current (6A peak) at supply voltages up to 55V DMOS power switch is an efficient low RDS ( ON), and a diode internal DMOS body structure, eliminating the typically required discrete diode clamp bipolar power stage.

An innovative current detection method, eliminating the power loss of the sense resistor in series with the motor, a 4-digit - analog converter (DAC), provides a digital control motor current path, and, by extension, to simplify the implementation of full, half and micro step motor driver application circuit LMD18245 this is a bipolar chopper drive stepper motor power stage. 20k resistor and 2.2 nF capacitor connected between the RC and set off time of about 48 microseconds, 20k resistor connected to the output and ground about 200 milliamperes per volt threshold is set to gain in the chopper CS.

Direction for digital signal control chopped threshold, winding current, by extension, drive type (full step, half step, and so on). Or a digital processor controller usually provide control signals.