battery isolator

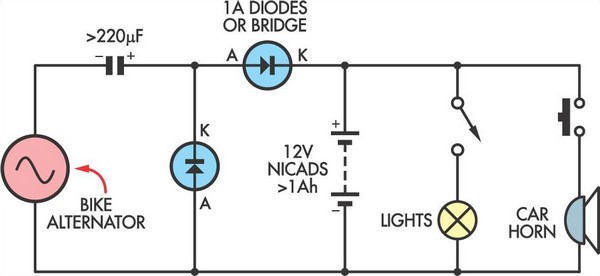

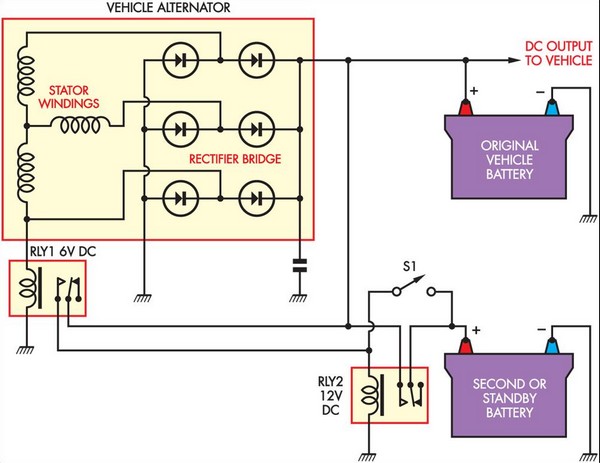

This circuit is straightforward and utilizes a 6V supply from one of the stator connections of the vehicle's alternator. This supply is connected to a 6V automotive relay (RLY1), which controls a Continuous Duty Solenoid (RLY2). The solenoid serves to electrically connect or isolate the batteries. When the engine starts and the alternator stator voltage increases, the 6V relay activates. This, in turn, energizes the Continuous Duty Solenoid, allowing the two batteries to be connected in parallel. While the engine is running, the vehicle's alternator maintains the charge in both batteries. Upon shutting down the engine, the alternator stator voltage decreases, causing the Continuous Duty Solenoid to deactivate, thereby isolating the second battery from the vehicle's electrical system. If camping accessories are solely linked to the second battery, the main battery will remain charged. The system operates automatically based on the alternator's stator output voltage, eliminating the need for manual operation.

The circuit design employs a 6V automotive relay (RLY1) that acts as a switch to control the operation of a Continuous Duty Solenoid (RLY2). The solenoid is crucial for managing the connection between the primary battery and the auxiliary battery, ensuring that both batteries can be charged while the engine is running. The relay is activated by the voltage generated from the vehicle's alternator stator, which typically provides a consistent voltage output when the engine is operational.

The Continuous Duty Solenoid is rated for continuous operation, allowing it to handle the load necessary for maintaining the parallel connection of the batteries without overheating or failing. This design is particularly beneficial for applications where auxiliary power is required, such as powering camping accessories or other electrical devices without draining the primary battery.

The automatic operation of the system is a significant advantage, as it eliminates the risk of forgetting to engage or disengage the battery connection. When the engine is turned off, the drop in voltage from the alternator stator results in the relay deactivating, which in turn cuts off the power to the solenoid. This ensures that the secondary battery is isolated, preserving its charge for future use.

Overall, this circuit provides a reliable and efficient solution for managing battery connections in vehicles, particularly for those used in recreational applications where auxiliary power is essential. The integration of the relay and solenoid into the system simplifies the operation and enhances the reliability of the vehicle's electrical management.This circuit is even simpler and employs a 6V feed from one of the stator connections on the vehicle`s alternator. This is connected to a 6V automotive relay (RLY1) which controls a Continuous Duty Solenoid (RLY2). This solenoid electrically connects or isolates the batteries. When the engine is started and the alternator stator voltage rises, the 6V relay turns on. This turns on the Continuous Duty Solenoid to connect the two batteries in parallel. As long as the engine is running, the vehicle`s alternator will maintain charge in both batteries. When the engine is shut down, the alternator stator voltage drops and the Continuous Duty Solenoid switches off, thus isolating the second battery from the vehicle`s electrical system. Provided that camping accessories are only connected to the second battery, the main battery should never discharge.

Because the concept is entirely dependent upon the alternator`s stator output voltage, you cannot forget to turn the system on or off as it happens automatically. 🔗 External reference

The circuit design employs a 6V automotive relay (RLY1) that acts as a switch to control the operation of a Continuous Duty Solenoid (RLY2). The solenoid is crucial for managing the connection between the primary battery and the auxiliary battery, ensuring that both batteries can be charged while the engine is running. The relay is activated by the voltage generated from the vehicle's alternator stator, which typically provides a consistent voltage output when the engine is operational.

The Continuous Duty Solenoid is rated for continuous operation, allowing it to handle the load necessary for maintaining the parallel connection of the batteries without overheating or failing. This design is particularly beneficial for applications where auxiliary power is required, such as powering camping accessories or other electrical devices without draining the primary battery.

The automatic operation of the system is a significant advantage, as it eliminates the risk of forgetting to engage or disengage the battery connection. When the engine is turned off, the drop in voltage from the alternator stator results in the relay deactivating, which in turn cuts off the power to the solenoid. This ensures that the secondary battery is isolated, preserving its charge for future use.

Overall, this circuit provides a reliable and efficient solution for managing battery connections in vehicles, particularly for those used in recreational applications where auxiliary power is essential. The integration of the relay and solenoid into the system simplifies the operation and enhances the reliability of the vehicle's electrical management.This circuit is even simpler and employs a 6V feed from one of the stator connections on the vehicle`s alternator. This is connected to a 6V automotive relay (RLY1) which controls a Continuous Duty Solenoid (RLY2). This solenoid electrically connects or isolates the batteries. When the engine is started and the alternator stator voltage rises, the 6V relay turns on. This turns on the Continuous Duty Solenoid to connect the two batteries in parallel. As long as the engine is running, the vehicle`s alternator will maintain charge in both batteries. When the engine is shut down, the alternator stator voltage drops and the Continuous Duty Solenoid switches off, thus isolating the second battery from the vehicle`s electrical system. Provided that camping accessories are only connected to the second battery, the main battery should never discharge.

Because the concept is entirely dependent upon the alternator`s stator output voltage, you cannot forget to turn the system on or off as it happens automatically. 🔗 External reference