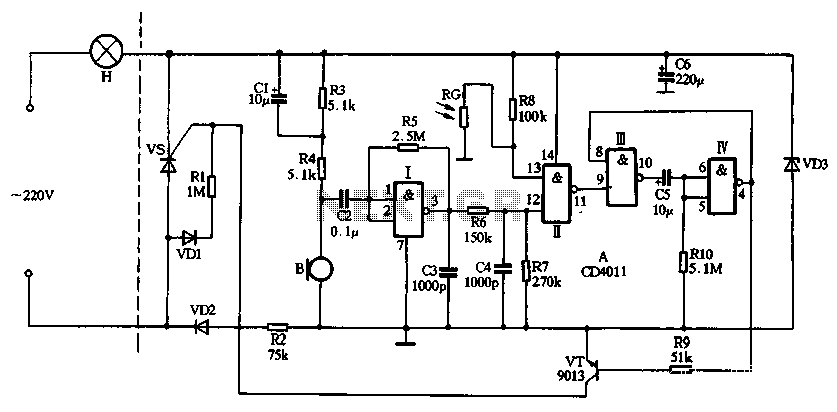

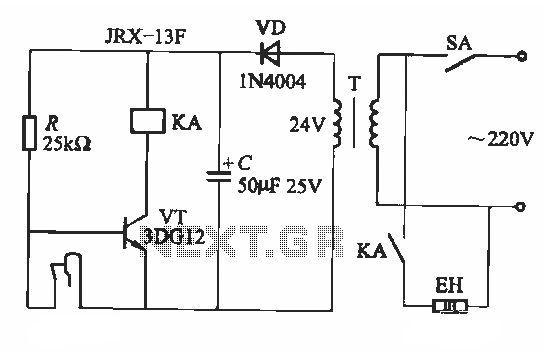

Bimetal thermostat control one circuit

A fluorescent starter bimetal can be utilized as a temperature sensing element for thermostatic control. This component consists of a double metal sheet designed for temperature sensing, resulting in a simple circuit that is easy to manufacture, although it exhibits poor control accuracy. The temperature sensor, made from bimetal, is housed within a neon bulb glass shell, which contains a solid set of U-shaped bimetal and a metal bar. To enhance temperature control accuracy, the upper end of the metal bar should be filed to a point and bent, allowing for precise adjustment of the bimetal's tip distance. This adjustment ensures that the U-shaped bimetal aligns with the tip of the metal rod for contact. It is recommended to observe the incubator temperature and perform the adjustment multiple times for optimal performance.

The fluorescent starter bimetal serves as a practical solution for temperature sensing in various applications, particularly in thermostatic controls. The design incorporates a bimetallic strip that bends in response to temperature changes, allowing for the opening and closing of contacts within the circuit. This mechanism is fundamental in controlling devices such as incubators, where maintaining a specific temperature is crucial.

The construction involves a U-shaped bimetal strip positioned within a glass shell, typically made of neon bulb material. The bimetal strip consists of two different metals bonded together, each with distinct thermal expansion properties. As the temperature rises, the bimetal strip bends, causing the metal bar to make or break contact with the electrical circuit.

For improved accuracy, the tip of the metal bar must be carefully shaped and positioned. This requires precise filing and bending to ensure that the bimetal's movement is effectively translated into the desired electrical response. The adjustment process may involve iterative testing, where the temperature within the incubator is monitored closely to determine the optimal alignment of the bimetal strip with the metal rod.

The overall simplicity of the circuit design allows for easy manufacturing and integration into existing systems, although it is important to note the limitations in control accuracy. Additional calibration may be necessary to achieve the desired performance, particularly in sensitive applications where temperature fluctuations can significantly impact outcomes. Proper installation and maintenance of the bimetal temperature sensor can enhance its reliability and longevity in operation.Use fluorescent starter bimetal can be prepared as a temperature sensing element, as the thermostatic control. Double metal sheet for temperature sensing element, the circuit is simple, easy to manufacture, but poor control accuracy. Circuit shown in Figure 11-39. Temperature sensor (bimetal) the production, lifted starter in neon bulb glass shell, leaving a solid set on the U-shaped glass beads bimetal and a metal bar. In order to more accurately control the temperature, the upper end of the metal bar should file tip, bent, and carefully adjusting the tip of the bimetal of the distance, so that the set temperature, U-shaped bimetal coincides with the tip of the metal rod with contact.

Adjustment should be observed with the incubator temperature within general be repeated several times to adjust the job.

The fluorescent starter bimetal serves as a practical solution for temperature sensing in various applications, particularly in thermostatic controls. The design incorporates a bimetallic strip that bends in response to temperature changes, allowing for the opening and closing of contacts within the circuit. This mechanism is fundamental in controlling devices such as incubators, where maintaining a specific temperature is crucial.

The construction involves a U-shaped bimetal strip positioned within a glass shell, typically made of neon bulb material. The bimetal strip consists of two different metals bonded together, each with distinct thermal expansion properties. As the temperature rises, the bimetal strip bends, causing the metal bar to make or break contact with the electrical circuit.

For improved accuracy, the tip of the metal bar must be carefully shaped and positioned. This requires precise filing and bending to ensure that the bimetal's movement is effectively translated into the desired electrical response. The adjustment process may involve iterative testing, where the temperature within the incubator is monitored closely to determine the optimal alignment of the bimetal strip with the metal rod.

The overall simplicity of the circuit design allows for easy manufacturing and integration into existing systems, although it is important to note the limitations in control accuracy. Additional calibration may be necessary to achieve the desired performance, particularly in sensitive applications where temperature fluctuations can significantly impact outcomes. Proper installation and maintenance of the bimetal temperature sensor can enhance its reliability and longevity in operation.Use fluorescent starter bimetal can be prepared as a temperature sensing element, as the thermostatic control. Double metal sheet for temperature sensing element, the circuit is simple, easy to manufacture, but poor control accuracy. Circuit shown in Figure 11-39. Temperature sensor (bimetal) the production, lifted starter in neon bulb glass shell, leaving a solid set on the U-shaped glass beads bimetal and a metal bar. In order to more accurately control the temperature, the upper end of the metal bar should file tip, bent, and carefully adjusting the tip of the bimetal of the distance, so that the set temperature, U-shaped bimetal coincides with the tip of the metal rod with contact.

Adjustment should be observed with the incubator temperature within general be repeated several times to adjust the job.