Boba Fett project movement

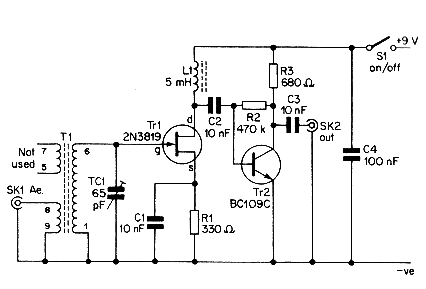

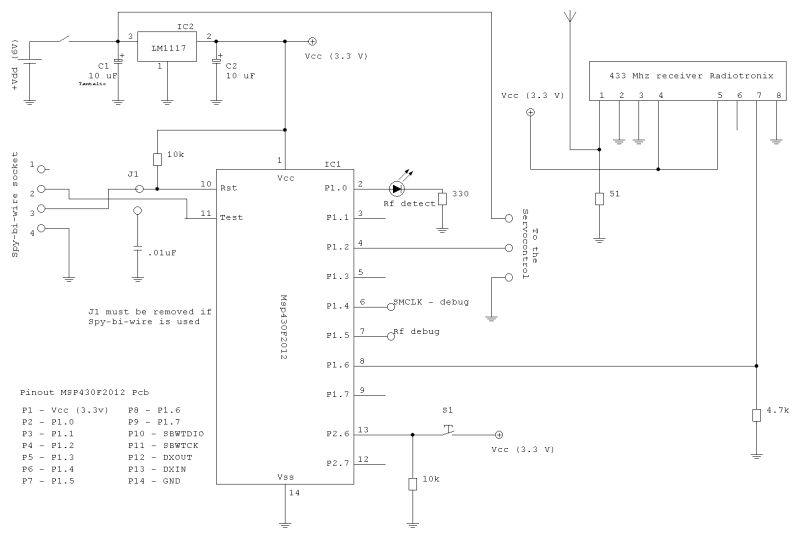

The timer generates a basic period (for instance, 20 ms), and with certain associated variables, it is possible to activate an I/O pin to produce a signal. By utilizing an 8-bit variable, the generated frequency can be divided into "chunks" of 256 (since 8 bits equal 256), allowing for 256 "steps," each measuring 0.078125 ms (20 ms / 256 = 0.078125). The start and end positions are immediately loaded into the duty cycle variable, enabling the servomotor to reach these positions at full speed whenever the S2 pushbutton is pressed. The frequency of the command pulse determines how quickly the servo executes the movement and the strength to maintain its position. The default frequency used is 50 Hz, as it provides the appropriate speed and feedback. The module is designed to accept a frequency rather than a simple on/off signal, meaning a precise frequency must indicate the triggering of the arm or ON condition, while the absence of this frequency signifies the OFF condition. After detecting the wave front, each timer interrupt (illustrated by the timer wave) triggers a reading of the input line, expecting a specific number of high readings and a specific number of low readings. In the absence of signals, the receiver may still capture some noise, which can occasionally match the frequency of the valid signal but only for a short duration.

The described timer circuit is integral for controlling a servomotor's movement with precision. The timer's ability to generate a consistent 20 ms period allows for fine control over the output signal frequency, which is essential for servomotor applications. The division of this period into 256 steps through an 8-bit variable provides a high resolution for position control, enabling the servomotor to respond accurately to user inputs.

The duty cycle variable plays a crucial role in determining the servomotor's position. By preloading the start and end positions, the system can ensure that the motor reaches its target position at maximum speed, enhancing responsiveness. The S2 pushbutton serves as a trigger, initiating the movement sequence, which is critical for applications requiring immediate action.

The choice of a 50 Hz frequency is significant; it strikes a balance between speed and feedback, allowing the servomotor to execute movements smoothly while maintaining stability in its position. The system's design to interpret frequency rather than simple on/off signals adds robustness, as it can differentiate between valid commands and noise. This capability is vital in noisy environments where interference could otherwise lead to erratic behavior.

The implementation of timer interrupts to monitor the input line further enhances the reliability of the system. By expecting a defined number of high and low readings, the circuit can effectively filter out noise, ensuring that only valid signals are acted upon. This approach mitigates the risk of false triggering due to transient disturbances.

Overall, this timer-based control mechanism for servomotors exemplifies a sophisticated approach to electronic design, leveraging precise timing and signal processing to achieve reliable and responsive control in various applications.the timer will generate the basic period (for example 20ms) and with some associated variables will be possible to "fire" an I/O pin to generate the signal. For example, using a 8 bit variable, we can divide the generated frequency in "chunks" of 256 (8 bit = 256), so basically we can have 256 "steps" each one of 0.

078125 ms (20 ms / 256 = 0. 078125). The start and end positions are loaded immediately in the duty cycle variable, so the servomotor can reach the positions at full speed every time the S2 pushbutton is pressed. The frequency of the command pulse determine how fast the servo "execute" the movement and the "strenght" to retain the position.

The default frequency used is 50 Hz because has the right speed and feedback speed. The module is designed to receive a frequency, not a simple on/off signal, so we have to assume a precise frequency as indication of triggering the arm, or ON condition, and the absence of this frequency as OFF condition. After that, knowing the front of the wave was detected, every timer interrupt (the wave below represent the timer) we read the input line and we expect a determined amount of readings high and a determined amount of readings low.

In absence of signals, the receiver picks up anyway some "noise", and this noise can sometime have the same frequency of the valid signal, but for short time. 🔗 External reference

The described timer circuit is integral for controlling a servomotor's movement with precision. The timer's ability to generate a consistent 20 ms period allows for fine control over the output signal frequency, which is essential for servomotor applications. The division of this period into 256 steps through an 8-bit variable provides a high resolution for position control, enabling the servomotor to respond accurately to user inputs.

The duty cycle variable plays a crucial role in determining the servomotor's position. By preloading the start and end positions, the system can ensure that the motor reaches its target position at maximum speed, enhancing responsiveness. The S2 pushbutton serves as a trigger, initiating the movement sequence, which is critical for applications requiring immediate action.

The choice of a 50 Hz frequency is significant; it strikes a balance between speed and feedback, allowing the servomotor to execute movements smoothly while maintaining stability in its position. The system's design to interpret frequency rather than simple on/off signals adds robustness, as it can differentiate between valid commands and noise. This capability is vital in noisy environments where interference could otherwise lead to erratic behavior.

The implementation of timer interrupts to monitor the input line further enhances the reliability of the system. By expecting a defined number of high and low readings, the circuit can effectively filter out noise, ensuring that only valid signals are acted upon. This approach mitigates the risk of false triggering due to transient disturbances.

Overall, this timer-based control mechanism for servomotors exemplifies a sophisticated approach to electronic design, leveraging precise timing and signal processing to achieve reliable and responsive control in various applications.the timer will generate the basic period (for example 20ms) and with some associated variables will be possible to "fire" an I/O pin to generate the signal. For example, using a 8 bit variable, we can divide the generated frequency in "chunks" of 256 (8 bit = 256), so basically we can have 256 "steps" each one of 0.

078125 ms (20 ms / 256 = 0. 078125). The start and end positions are loaded immediately in the duty cycle variable, so the servomotor can reach the positions at full speed every time the S2 pushbutton is pressed. The frequency of the command pulse determine how fast the servo "execute" the movement and the "strenght" to retain the position.

The default frequency used is 50 Hz because has the right speed and feedback speed. The module is designed to receive a frequency, not a simple on/off signal, so we have to assume a precise frequency as indication of triggering the arm, or ON condition, and the absence of this frequency as OFF condition. After that, knowing the front of the wave was detected, every timer interrupt (the wave below represent the timer) we read the input line and we expect a determined amount of readings high and a determined amount of readings low.

In absence of signals, the receiver picks up anyway some "noise", and this noise can sometime have the same frequency of the valid signal, but for short time. 🔗 External reference