Boost Converter Design

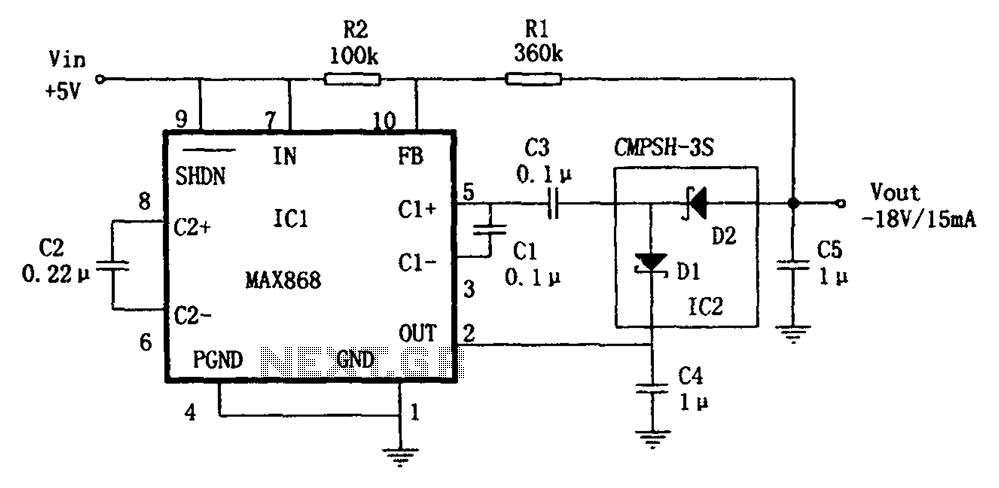

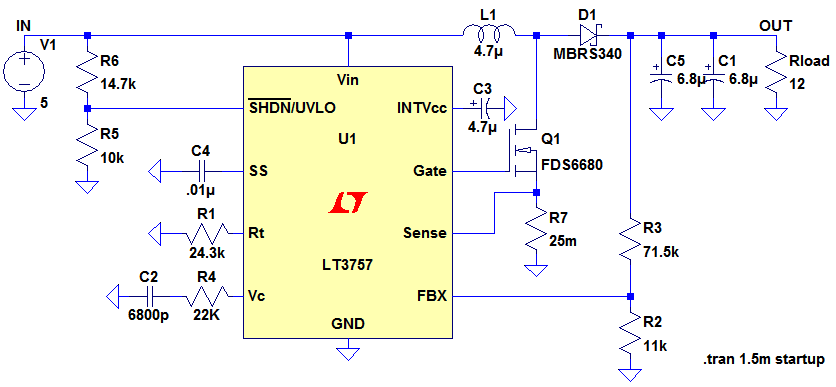

Ignore components C1, C2, R3. The MOSFET, Q1, switches on, creating a short circuit between the right-hand side of the inductor, L1, and ground (0V). A fixed voltage of 3.3V is applied across the inductor, causing its current to ramp up. When the MOSFET turns off, the inductor attempts to maintain its current flow by generating a voltage across its terminals, similar to a battery, where current flows from the negative terminal through the battery to the positive terminal. In the circuit, to maintain current flow, the voltage on the right side of the inductor must increase with respect to the left side. Since the left side is connected to the input voltage and cannot change, the right side's voltage rises above the input voltage until conduction occurs. Theoretically, this voltage can rise to an infinite value, making the inductor effective at generating high voltages from low voltages. The inductor voltage increases until diode D1 conducts, allowing the energy stored in the inductor to flow into the output capacitor, C3, causing its voltage to increase slightly. Before the MOSFET begins switching, there exists a DC path from the input, through L1 and diode D1 into C3, allowing C3 to charge to a voltage equal to Vin minus Vdiode. Once the inductor discharges, the MOSFET turns on again, and the process repeats, generating pulses of energy from the inductor into the output capacitor, thereby increasing the voltage across C3. Resistors R1 and R2 monitor the output voltage; when the voltage at the feedback (FB) pin reaches a predetermined threshold, the controller IC ceases to drive the MOSFET until the output capacitor voltage drops. The blue waveform represents the gate voltage to the MOSFET. When the FET turns on, the inductor current (shown in red) ramps up from 1.09A to 2.18A in 739ns, translating to a rate of 1.474 million Amps per second, which is close to calculated expectations. The difference arises because the FET does not provide a perfect short circuit to ground and has an approximate voltage drop of 50mV when activated, thus reducing the effective voltage across the inductor. Once the output achieves regulation, the voltage across the inductor can be expressed as [(5 + Vd) - 3.3], where Vd is the diode voltage drop (approximately 0.5V). This allows for the calculation of the current ramp to approximately 1 million Amps per second. Over a period of 1.083μs, the current decreases by 1.083A, confirming that the LTspice simulation closely aligns with calculated values. It is noteworthy that the di/dt value is solely determined by the inductance and the voltage across the inductor, independent of the controller IC. The duty cycle is dictated only by the input and output voltages, with the inductor value not influencing this parameter as long as the inductor current remains above zero, indicating Continuous Conduction Mode (CCM). If the inductor current drops to zero, the duty cycle equation becomes invalid, and the controller transitions to Discontinuous Conduction Mode (DCM). In CCM, an increase in load current does not alter the duty cycle in steady state; the circuit compensates by increasing the midpoint of the inductor current while maintaining the switching frequency and amplitude of the inductor ripple current. In the provided figures, the midpoint of the inductor current is approximately 1.65A, with a ripple amplitude of 1.1A. An increase in load results in a higher midpoint of the current, but the inductor ripple current remains constant at 1.1A.

The described circuit operates as a boost converter, utilizing a MOSFET to switch the inductor, L1, on and off, thereby transferring energy to the output capacitor, C3. The MOSFET Q1 plays a crucial role in controlling the energy flow from the inductor to the output. During the ON state of Q1, the inductor is energized by the input voltage, allowing current to build up. The inductor's behavior is governed by its inductance value and the applied voltage, which together determine the rate of current change (di/dt).

When Q1 is switched off, the inductor's stored energy is released, and the voltage at its terminals rises to maintain the current flow. This action generates a back EMF that can significantly exceed the input voltage, leading to the conduction of diode D1. The output capacitor, C3, is charged by this energy pulse, resulting in an increase in output voltage. The presence of resistors R1 and R2 allows for feedback control, ensuring that the output voltage is regulated by adjusting the duty cycle of the MOSFET.

The circuit operates effectively in Continuous Conduction Mode (CCM) when the inductor current remains above zero. Under these conditions, the duty cycle remains constant even with variations in load current, as the controller adjusts the inductor current's DC offset rather than the duty cycle itself. In contrast, if the load demand exceeds the capability of the circuit, the inductor current may drop to zero, switching the operation to Discontinuous Conduction Mode (DCM), where the control dynamics change significantly.

The design emphasizes the importance of the inductor's characteristics and the control strategy employed by the IC, highlighting the relationship between input and output voltages in establishing the duty cycle. This method of operation allows the boost converter to efficiently convert lower voltages to higher output levels while maintaining stable performance across varying load conditions.Ignore components C1, C2, R3. The MOSFET, Q1, switches on creating a short circuit between the right hand side of the inductor, L1, and 0V. Thus a fixed voltage of 3. 3V is applied across the inductor, so its current will ramp up according to When the MOSFET switches off, the inductor tries to maintain its current flow.

It does this by generating a voltage across its terminals very similar to a battery, where the current flows from the negative terminal, through the battery, to the positive terminal. In the circuit of FIG 1, we can see that to maintain current flow, the right hand side of the inductor has to increase in voltage with respect to the left hand side.

The left hand side is connected to the input voltage (so cannot change), thus the right hand side voltage increases above the input voltage and continues to do so until something conducts. Theoretically, this voltage will rise to an infinite value, making the inductor very good at generating high voltages from low voltages.

In FIG 1, the inductor voltage increases until diode D1 conducts after which the energy in the inductor flows into the output capacitor C3, causing the voltage across C3 to increase slightly. It is worth noting that even before the MOSFET has started to switch, there is a dc path flowing from the input, through L1 and diode D1 into C3, so at startup C3 will have a voltage across it (equal to Vin Vdiode).

When the inductor has discharged, the MOSFET switches on and the process starts again. Repeating this process produces pulses of energy from the inductor into the output capacitor making the voltage across the output capacitor rise. In FIG1, resistors R1 and R2 monitor the output voltage and when the voltage at the FB pin reaches a certain point, the chip terminates the drive to the MOSFET until the voltage on the output capacitor droops.

The blue waveform is the Gate voltage to the MOSFET. When the FET turns on, the inductor current (in red) ramps up from 1. 09A to 2. 18A in 739ns (this can be measured in LTspice), or at a rate of 1. 474 million Amps per second, close to what we calculated above. The discrepancy is due to the fact that the FET does not provide a true short circuit to ground and actually has a voltage across it of approximately 50mV when switched on, thus reducing the voltage across the inductor. once the output has reached regulation the voltage across the inductor is [(5+Vd) - 3. 3], where Vd is the voltage across the diode (approx. 0. 5V), so we can calculate the current ramp to be or 1 million amps per second. Over a period of 1. 083us, the current ramps down by 1. 083A, so again our LTspice simulation is very close to the calculated value. It is interesting to note that the value of di/dt is determined ONLY by the inductance value and the voltage across the inductor.

The controller IC has nothing to do with setting the inductor ramp current. Again, the duty cycle is set by the input and output voltages only. The inductor value does not feature in setting the duty cycle, nor does the controller IC. The above is true as long as the current in the inductor does not fall to zero. This is called Continuous Conduction Mode (CCM). If the inductor current falls to zero, the duty cycle equation above does not hold and the controller enters Discontinuous Conduction Mode (DCM). In CCM, if the load current increases, the duty cycle remains unchanged (in steady state). The circuit reacts to the increase in load current by keeping the duty cycle constant, but the midpoint of the inductor current (its dc offset) increases.

The switching frequency and the amplitude of the inductor ripple current remain unchanged. In FIG 2, the midpoint of the inductor current is approximately 1. 65A and the ripple amplitude is 1. 1A. If the load increases the midpoint of the current will increase, but the inductor ripple current will still be 1. 1A. In a boost converter, the average input current 🔗 External reference

The described circuit operates as a boost converter, utilizing a MOSFET to switch the inductor, L1, on and off, thereby transferring energy to the output capacitor, C3. The MOSFET Q1 plays a crucial role in controlling the energy flow from the inductor to the output. During the ON state of Q1, the inductor is energized by the input voltage, allowing current to build up. The inductor's behavior is governed by its inductance value and the applied voltage, which together determine the rate of current change (di/dt).

When Q1 is switched off, the inductor's stored energy is released, and the voltage at its terminals rises to maintain the current flow. This action generates a back EMF that can significantly exceed the input voltage, leading to the conduction of diode D1. The output capacitor, C3, is charged by this energy pulse, resulting in an increase in output voltage. The presence of resistors R1 and R2 allows for feedback control, ensuring that the output voltage is regulated by adjusting the duty cycle of the MOSFET.

The circuit operates effectively in Continuous Conduction Mode (CCM) when the inductor current remains above zero. Under these conditions, the duty cycle remains constant even with variations in load current, as the controller adjusts the inductor current's DC offset rather than the duty cycle itself. In contrast, if the load demand exceeds the capability of the circuit, the inductor current may drop to zero, switching the operation to Discontinuous Conduction Mode (DCM), where the control dynamics change significantly.

The design emphasizes the importance of the inductor's characteristics and the control strategy employed by the IC, highlighting the relationship between input and output voltages in establishing the duty cycle. This method of operation allows the boost converter to efficiently convert lower voltages to higher output levels while maintaining stable performance across varying load conditions.Ignore components C1, C2, R3. The MOSFET, Q1, switches on creating a short circuit between the right hand side of the inductor, L1, and 0V. Thus a fixed voltage of 3. 3V is applied across the inductor, so its current will ramp up according to When the MOSFET switches off, the inductor tries to maintain its current flow.

It does this by generating a voltage across its terminals very similar to a battery, where the current flows from the negative terminal, through the battery, to the positive terminal. In the circuit of FIG 1, we can see that to maintain current flow, the right hand side of the inductor has to increase in voltage with respect to the left hand side.

The left hand side is connected to the input voltage (so cannot change), thus the right hand side voltage increases above the input voltage and continues to do so until something conducts. Theoretically, this voltage will rise to an infinite value, making the inductor very good at generating high voltages from low voltages.

In FIG 1, the inductor voltage increases until diode D1 conducts after which the energy in the inductor flows into the output capacitor C3, causing the voltage across C3 to increase slightly. It is worth noting that even before the MOSFET has started to switch, there is a dc path flowing from the input, through L1 and diode D1 into C3, so at startup C3 will have a voltage across it (equal to Vin Vdiode).

When the inductor has discharged, the MOSFET switches on and the process starts again. Repeating this process produces pulses of energy from the inductor into the output capacitor making the voltage across the output capacitor rise. In FIG1, resistors R1 and R2 monitor the output voltage and when the voltage at the FB pin reaches a certain point, the chip terminates the drive to the MOSFET until the voltage on the output capacitor droops.

The blue waveform is the Gate voltage to the MOSFET. When the FET turns on, the inductor current (in red) ramps up from 1. 09A to 2. 18A in 739ns (this can be measured in LTspice), or at a rate of 1. 474 million Amps per second, close to what we calculated above. The discrepancy is due to the fact that the FET does not provide a true short circuit to ground and actually has a voltage across it of approximately 50mV when switched on, thus reducing the voltage across the inductor. once the output has reached regulation the voltage across the inductor is [(5+Vd) - 3. 3], where Vd is the voltage across the diode (approx. 0. 5V), so we can calculate the current ramp to be or 1 million amps per second. Over a period of 1. 083us, the current ramps down by 1. 083A, so again our LTspice simulation is very close to the calculated value. It is interesting to note that the value of di/dt is determined ONLY by the inductance value and the voltage across the inductor.

The controller IC has nothing to do with setting the inductor ramp current. Again, the duty cycle is set by the input and output voltages only. The inductor value does not feature in setting the duty cycle, nor does the controller IC. The above is true as long as the current in the inductor does not fall to zero. This is called Continuous Conduction Mode (CCM). If the inductor current falls to zero, the duty cycle equation above does not hold and the controller enters Discontinuous Conduction Mode (DCM). In CCM, if the load current increases, the duty cycle remains unchanged (in steady state). The circuit reacts to the increase in load current by keeping the duty cycle constant, but the midpoint of the inductor current (its dc offset) increases.

The switching frequency and the amplitude of the inductor ripple current remain unchanged. In FIG 2, the midpoint of the inductor current is approximately 1. 65A and the ripple amplitude is 1. 1A. If the load increases the midpoint of the current will increase, but the inductor ripple current will still be 1. 1A. In a boost converter, the average input current 🔗 External reference