Capacitive level measuring circuit

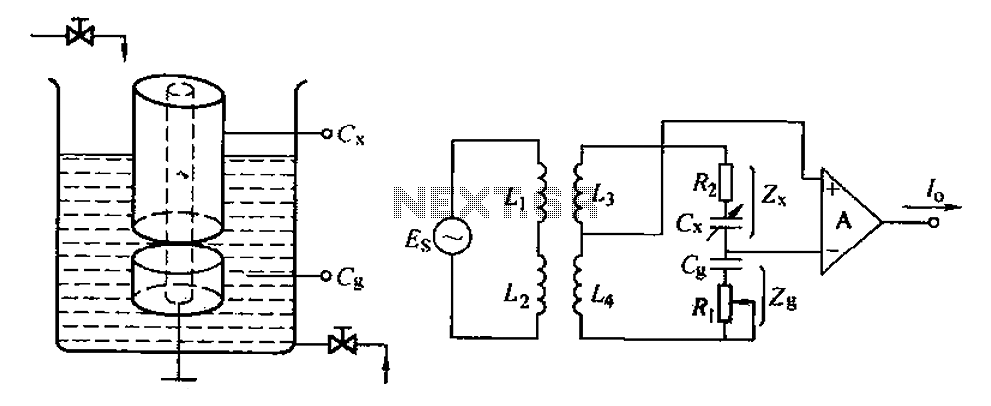

The capacitance change in a capacitive sensor is directly converted into electrical parameters, which are then unified for signal transmission, processing, and display. These electrical parameters can be categorized into resistive, capacitive, and inductive types. This explanation focuses on capacitive sensors. A basic capacitor's capacitance can change based on variations in the distance (d), permittivity (E), or area (A) of the plates, leading to the design of corresponding capacitive sensors. A capacitive level meter comprises capacitive sensors and a measuring circuit. Capacitive sensors operate on the principle of changing the dielectric constant (E). The setup involves a cylindrical capacitor immersed in a test solution, where the plate area (A) and distance (d) remain constant, leading to a capacitance value (C). The dielectric medium between the plates varies in dielectric constant (E). When the liquid level rises, the total dielectric constant increases, resulting in a higher capacitance value (C), and conversely, a decrease in liquid level leads to a reduction in capacitance. Consequently, measuring the change in capacitance allows for determining the liquid level within a container. The measuring circuit includes a reference arm capacitance (G).

The capacitive level meter operates under the principle of capacitance variation due to changes in the dielectric medium between the capacitor plates. The sensor typically consists of two conductive plates separated by a dielectric material, which can be air, liquid, or solid. When the level of a liquid rises, the dielectric constant of the medium between the plates alters, leading to an increase in capacitance. This change can be mathematically represented by the formula:

\[ C = \frac{εA}{d} \]

where \( C \) is the capacitance, \( ε \) is the dielectric constant of the medium, \( A \) is the area of the plates, and \( d \) is the distance between them. As the liquid level increases, the effective dielectric constant increases, resulting in a higher capacitance reading. Conversely, as the liquid level decreases, the dielectric constant reduces, leading to a lower capacitance.

The measuring circuit designed for this capacitive sensor typically includes a capacitor reference arm (G) and associated electronics that can process the changes in capacitance. This circuit can convert the capacitance value into a readable signal, suitable for display or further processing. The output signal can be analog or digital, depending on the design requirements. In practical applications, the capacitive level meter is widely used in various industries for fluid level monitoring, providing a non-invasive and reliable method for measuring liquid levels in tanks, silos, and other containers. Capacitance/C tuck bit IJ volume level change is directly converted into electrical parameters, electrical parameters and then be converted to a unified signal transmission, pr ocessing, display and so on. The electrical parameters can be divided into different: resistive, capacitive and inductive and so on, now capacitive for the introduction. We know that the most simple capacitor capacitance from the above equation by changing the t d, E or A change of approach could be made, respectively, the corresponding capacitive sensor.

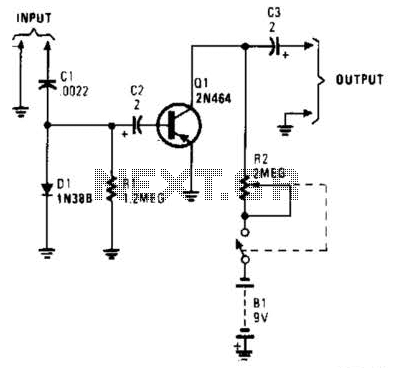

Capacitive level meter consists of capacitive sensors and measuring circuit. Capacitive sensors by changing the dielectric constant E of the general principle made, FIG. 6-38a, b capacitive liquid level sensors and measuring circuits. In setting a cylindrical capacitor test solution at the plate area A and distance d is fixed, the capacitance Velvet C. The dielectric medium between the plates with dielectric constant E change. Let the liquid dielectric permittivity, Tuen constant gas is e2, general E, ez, when the liquid level rises, the total dielectric constant increases.

Thus the capacitance G increases, and vice versa, when the level drops Rang, E decreases. c, decreases. It is possible that by measuring the C rhyme change the level of liquid in the container. Figure 6-38b capacitance measuring circuit, G is the reference arm capacitance.

The capacitive level meter operates under the principle of capacitance variation due to changes in the dielectric medium between the capacitor plates. The sensor typically consists of two conductive plates separated by a dielectric material, which can be air, liquid, or solid. When the level of a liquid rises, the dielectric constant of the medium between the plates alters, leading to an increase in capacitance. This change can be mathematically represented by the formula:

\[ C = \frac{εA}{d} \]

where \( C \) is the capacitance, \( ε \) is the dielectric constant of the medium, \( A \) is the area of the plates, and \( d \) is the distance between them. As the liquid level increases, the effective dielectric constant increases, resulting in a higher capacitance reading. Conversely, as the liquid level decreases, the dielectric constant reduces, leading to a lower capacitance.

The measuring circuit designed for this capacitive sensor typically includes a capacitor reference arm (G) and associated electronics that can process the changes in capacitance. This circuit can convert the capacitance value into a readable signal, suitable for display or further processing. The output signal can be analog or digital, depending on the design requirements. In practical applications, the capacitive level meter is widely used in various industries for fluid level monitoring, providing a non-invasive and reliable method for measuring liquid levels in tanks, silos, and other containers. Capacitance/C tuck bit IJ volume level change is directly converted into electrical parameters, electrical parameters and then be converted to a unified signal transmission, pr ocessing, display and so on. The electrical parameters can be divided into different: resistive, capacitive and inductive and so on, now capacitive for the introduction. We know that the most simple capacitor capacitance from the above equation by changing the t d, E or A change of approach could be made, respectively, the corresponding capacitive sensor.

Capacitive level meter consists of capacitive sensors and measuring circuit. Capacitive sensors by changing the dielectric constant E of the general principle made, FIG. 6-38a, b capacitive liquid level sensors and measuring circuits. In setting a cylindrical capacitor test solution at the plate area A and distance d is fixed, the capacitance Velvet C. The dielectric medium between the plates with dielectric constant E change. Let the liquid dielectric permittivity, Tuen constant gas is e2, general E, ez, when the liquid level rises, the total dielectric constant increases.

Thus the capacitance G increases, and vice versa, when the level drops Rang, E decreases. c, decreases. It is possible that by measuring the C rhyme change the level of liquid in the container. Figure 6-38b capacitance measuring circuit, G is the reference arm capacitance.