Gas Generator Voltage Control Circuit

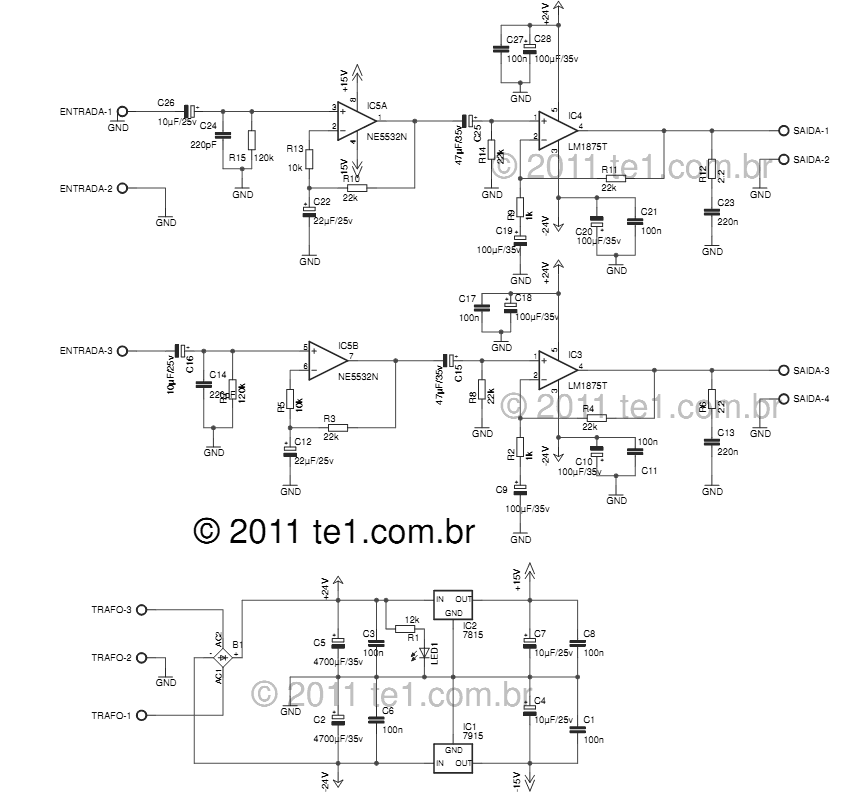

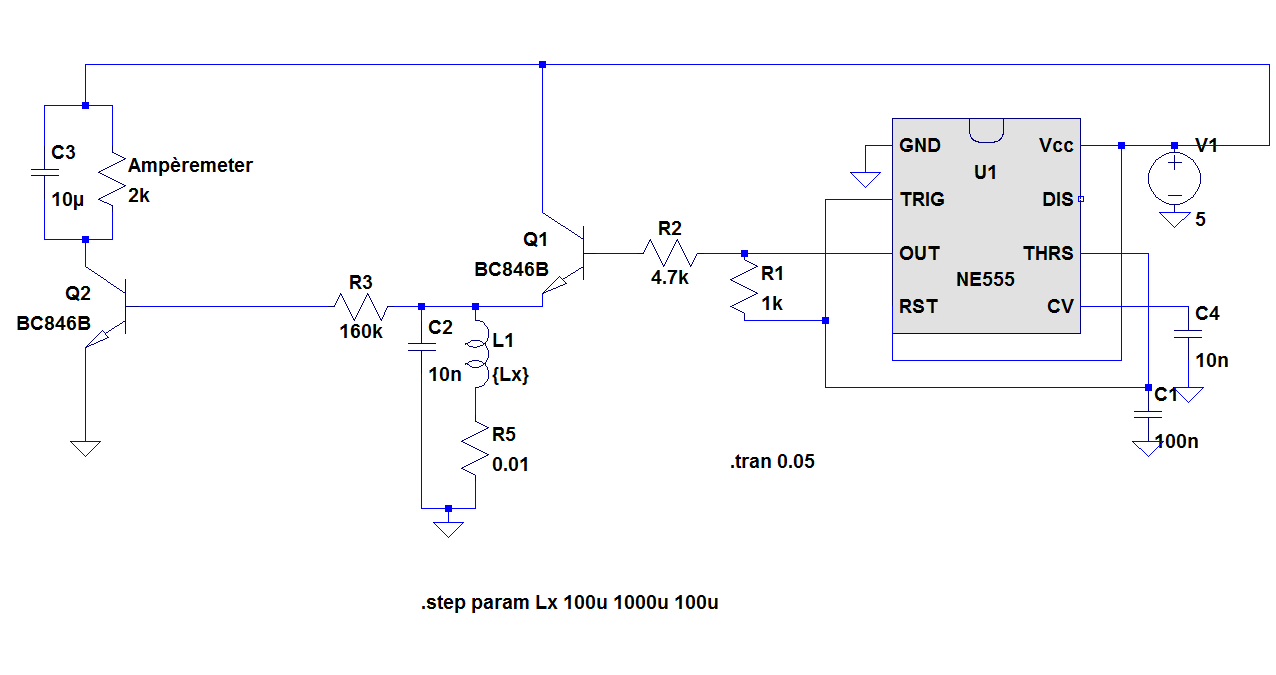

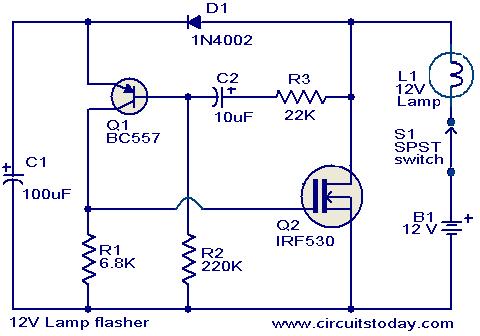

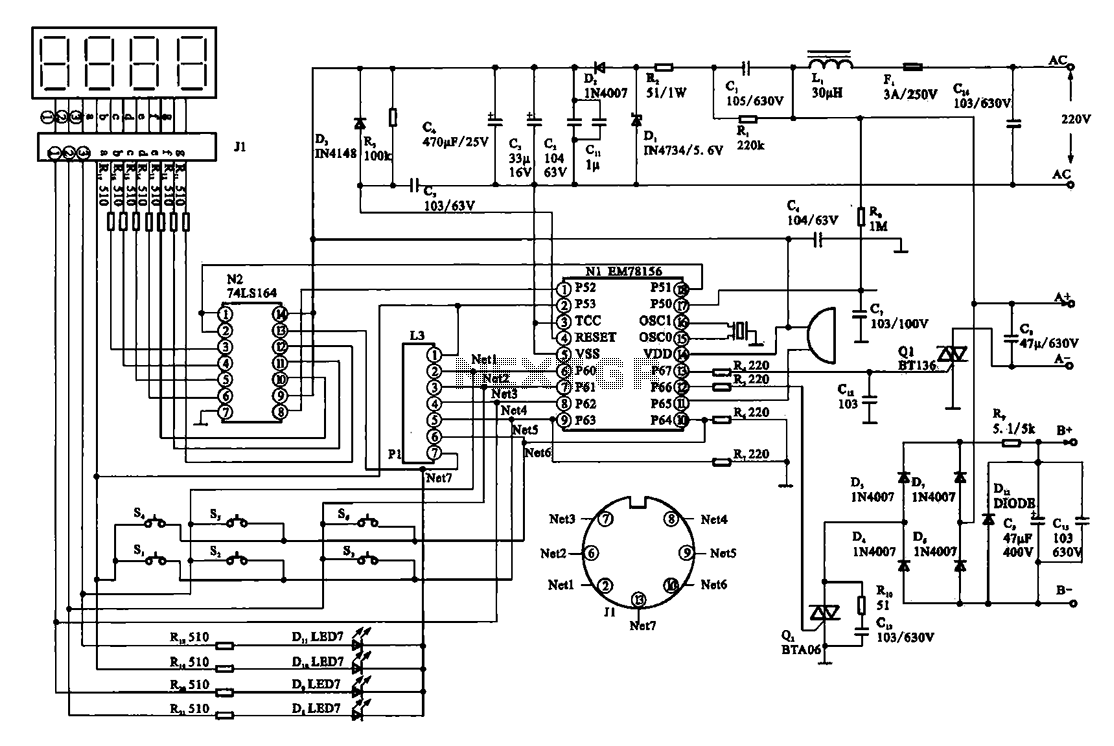

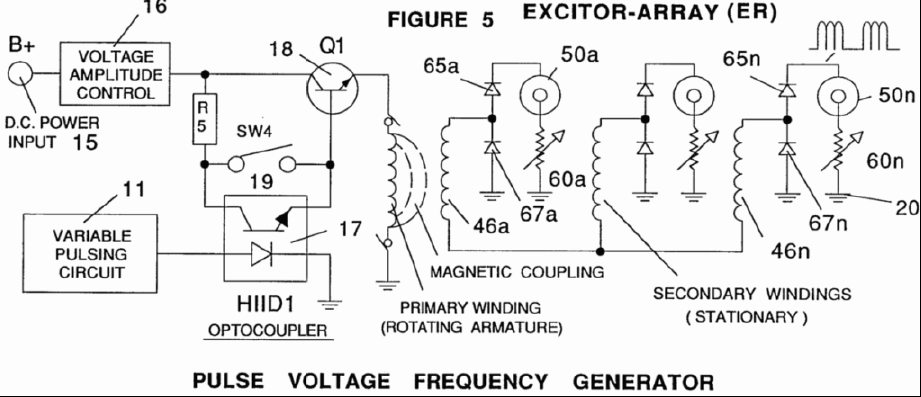

A power supply system utilizes a generator as a source of fuel to separate hydrogen and oxygen gases from natural water. It has the capability to control gas production by varying the amplitude of the voltage and/or the pulse repetition rate of the voltage pulses applied to a pair of plate exciters in a vessel of natural water. This system comprises a sequence of circuitry designed to limit the current of a direct current (d.c.) potential to a minimum value relative to the voltage applied to the plate exciters. Each circuit functions up to a specified voltage magnitude to inhibit and curtail electron flow from the plate exciter with the negative voltage potential. The first circuit, operating at a specific voltage magnitude, converts the voltage potential applied to the plate exciters into unipolar pulse voltage d.c. at a repetitive frequency. The subsequent circuit varies the duty cycle of the unipolar pulse voltage d.c., followed by rearranging the voltage application to the individual exciters, allowing independent voltage application to each plate exciter in the generator. The next circuit includes an electron inhibitor that prevents electron flow, positioned in the terminal line between the negative plate exciter and ground. In applications where excessively high voltage is applied to the plate exciters for increased gas yield, a second electron inhibitor with a unique structure is connected in series with the first inhibitor. This second inhibitor has a relatively fixed value, while the first inhibitor is variable, allowing fine-tuning of the circuits to eliminate current flow. The generator produces a mixture of hydrogen, oxygen, and other dissolved gases from natural water, utilizing at least a pair of plate exciters within a water-containing vessel. A variable voltage source applies a pulsating predetermined potential difference between the plates, with the gas production rate controlled by varying the amplitude of the voltage and the pulse repetition rate of the applied potential difference. The variable voltage source includes a mechanism to restrict current flow between the plate exciters to a minimum value relative to the applied potential difference. The improvement in the current flow restriction means includes a variable voltage source that converts an input voltage potential to unipolar d.c. voltage pulses applied to the exciter plates, producing a pulsating potential difference with respect to an arbitrary ground. Additionally, there is a means for regulating the voltage pulses at a repetitive frequency to inhibit current flow due to electron leakage between the plate exciters, ensuring that the current flow does not exceed a first minimum level. The input voltage is an alternating current (AC) voltage, and the circuit for converting this AC voltage to unipolar d.c. voltage pulses includes a means for varying the frequency of the AC input to further inhibit electron leakage as the voltage applied to the plate exciters increases to a second level. The variable voltage source is designed to convert AC voltage to unipolar d.c. voltage pulses and includes a transformer with primary and secondary windings, along with a rectifier circuit connected across the secondary windings. The transformer also incorporates variable inductive means to adjust the output frequency of the voltage induced in the secondary winding, further inhibiting electron leakage.

The described power supply system is a sophisticated arrangement designed to optimize the electrolysis process by precisely controlling the electrical parameters applied to the plate exciters. The implementation of variable voltage sources and electronic control mechanisms allows for enhanced efficiency in gas production. The use of unipolar pulse voltage d.c. not only aids in reducing electron flow but also contributes to the stability of the electrolysis process by minimizing unwanted reactions that could occur from excessive current flow.

The inclusion of an electron inhibitor circuit plays a critical role in maintaining the integrity of the system by preventing short circuits and ensuring that the current remains within safe operational limits. The ability to fine-tune the parameters of the first and second electron inhibitors allows for adaptability in various operational scenarios, accommodating different water qualities and desired gas output rates.

Furthermore, the transformer design, with its variable inductive capabilities, is essential for achieving the desired frequency adjustments that directly influence the electrolysis efficiency. By controlling the frequency of the input AC voltage, the system can dynamically respond to changing conditions, optimizing the electrolysis process in real-time.

Overall, this power supply system represents a significant advancement in the field of electrolysis, specifically for hydrogen and oxygen generation from water, combining innovative circuit designs with practical applications for energy generation and storage.A power supply in a system utilizing as a source of fuel a generator for separating hydrogen and oxygen gasses from natural water and having the capabilities to control the production of gasses by varying the amplitude of the voltage and/or the pulse repetition rate of the voltage pulses applied to a pair of plate exciters in a vessel of natural w ater, comprising a sequence of circuitry operative to limit the current of a d. c. potential to a minimum value relative to the magnitude of the voltage applied to the plate exciters. The circuits each function up to a given magnitude of voltage to inhibit and curtail the flow of electrons from the plate exciter having the negative voltage potential applied thereto. The first circuit operative from a first magnitude of voltage comprises converting the voltage potential applied to the plate exciters to a unipolar pulse voltage d.

c. of a repetitive frequency. The next circuit varies the duty cycle of the unipolar pulse voltage d. c. ; followed by rearranging the application of the voltage to the exciters to individual exciters each having the voltage applied thereto independently of the other plate exciters in the generator. The next circuit comprises an electron inhibitor that prevents the flow of electrons; the circuit being in the terminal line between the negative plate exciter and ground.

In those applications of the generator wherein excessively high voltage is to be applied to the plate exciters for a very high yield of gasses, a second electron inhibitor of a unique structure is serially connected with the first electron inhibiter. The second named inhibiter having a relatively fixed value and the first inhibiter connected in series is variable to fine tune the circuits to eliminate current flow.

In a generator for producing a mixture of hydrogen and oxygen and other dissolved gas from natural water which generator includes at least a pair of plate exciters within a water containing vessel, a variable voltage source for applying a pulsating predetermined potential difference between the plates and wherein the rate of production of the mixture of gasses is controlled by varying at least one of the amplitude of the voltage and the pulse repetition rate of the pulsating potential difference applied to the plate exciters. The variable voltage source includes a means for restricting the current flow between the plate exciters to a minimum value relative to a predetermined potential difference applied to the plates, the improvement in the means for restricting said current flow comprising: variable voltage source means for converting an input voltage potential to unipolar d.

c. voltage pulses that are applied to the exciter plates and have a pulsating potential difference when measured from an arbitrary ground. There is also a means for regulating the voltage pulses in a repetitive frequency to inhibit the current flow caused by electron leakage between the plate exciters resulting from the amplitude of the applied voltage potential whereby said current flow is inhibited from exceeding a first minimum level.

The input voltage is an alternating current voltage and said circuit for converting said alternating current voltage to unipolar d. c. voltage pulses further comprises, means for varying the frequency of said alternating current voltage input to further inhibit electron leakage upon increasing the amplitude of the voltage applied to the plate exciters to a second level.

The variable voltage source is an alternating current voltage for converting alternating current voltage to unipolar d. c. voltage pulses also comprises a transformer having primary and secondary windings, and a rectifier circuit connected across said secondary windings.

The transformer further includes variable inductive means for varying the output frequency of the voltage induced in said secondary winding to further inhibit electron leakage upon in 🔗 External reference

The described power supply system is a sophisticated arrangement designed to optimize the electrolysis process by precisely controlling the electrical parameters applied to the plate exciters. The implementation of variable voltage sources and electronic control mechanisms allows for enhanced efficiency in gas production. The use of unipolar pulse voltage d.c. not only aids in reducing electron flow but also contributes to the stability of the electrolysis process by minimizing unwanted reactions that could occur from excessive current flow.

The inclusion of an electron inhibitor circuit plays a critical role in maintaining the integrity of the system by preventing short circuits and ensuring that the current remains within safe operational limits. The ability to fine-tune the parameters of the first and second electron inhibitors allows for adaptability in various operational scenarios, accommodating different water qualities and desired gas output rates.

Furthermore, the transformer design, with its variable inductive capabilities, is essential for achieving the desired frequency adjustments that directly influence the electrolysis efficiency. By controlling the frequency of the input AC voltage, the system can dynamically respond to changing conditions, optimizing the electrolysis process in real-time.

Overall, this power supply system represents a significant advancement in the field of electrolysis, specifically for hydrogen and oxygen generation from water, combining innovative circuit designs with practical applications for energy generation and storage.A power supply in a system utilizing as a source of fuel a generator for separating hydrogen and oxygen gasses from natural water and having the capabilities to control the production of gasses by varying the amplitude of the voltage and/or the pulse repetition rate of the voltage pulses applied to a pair of plate exciters in a vessel of natural w ater, comprising a sequence of circuitry operative to limit the current of a d. c. potential to a minimum value relative to the magnitude of the voltage applied to the plate exciters. The circuits each function up to a given magnitude of voltage to inhibit and curtail the flow of electrons from the plate exciter having the negative voltage potential applied thereto. The first circuit operative from a first magnitude of voltage comprises converting the voltage potential applied to the plate exciters to a unipolar pulse voltage d.

c. of a repetitive frequency. The next circuit varies the duty cycle of the unipolar pulse voltage d. c. ; followed by rearranging the application of the voltage to the exciters to individual exciters each having the voltage applied thereto independently of the other plate exciters in the generator. The next circuit comprises an electron inhibitor that prevents the flow of electrons; the circuit being in the terminal line between the negative plate exciter and ground.

In those applications of the generator wherein excessively high voltage is to be applied to the plate exciters for a very high yield of gasses, a second electron inhibitor of a unique structure is serially connected with the first electron inhibiter. The second named inhibiter having a relatively fixed value and the first inhibiter connected in series is variable to fine tune the circuits to eliminate current flow.

In a generator for producing a mixture of hydrogen and oxygen and other dissolved gas from natural water which generator includes at least a pair of plate exciters within a water containing vessel, a variable voltage source for applying a pulsating predetermined potential difference between the plates and wherein the rate of production of the mixture of gasses is controlled by varying at least one of the amplitude of the voltage and the pulse repetition rate of the pulsating potential difference applied to the plate exciters. The variable voltage source includes a means for restricting the current flow between the plate exciters to a minimum value relative to a predetermined potential difference applied to the plates, the improvement in the means for restricting said current flow comprising: variable voltage source means for converting an input voltage potential to unipolar d.

c. voltage pulses that are applied to the exciter plates and have a pulsating potential difference when measured from an arbitrary ground. There is also a means for regulating the voltage pulses in a repetitive frequency to inhibit the current flow caused by electron leakage between the plate exciters resulting from the amplitude of the applied voltage potential whereby said current flow is inhibited from exceeding a first minimum level.

The input voltage is an alternating current voltage and said circuit for converting said alternating current voltage to unipolar d. c. voltage pulses further comprises, means for varying the frequency of said alternating current voltage input to further inhibit electron leakage upon increasing the amplitude of the voltage applied to the plate exciters to a second level.

The variable voltage source is an alternating current voltage for converting alternating current voltage to unipolar d. c. voltage pulses also comprises a transformer having primary and secondary windings, and a rectifier circuit connected across said secondary windings.

The transformer further includes variable inductive means for varying the output frequency of the voltage induced in said secondary winding to further inhibit electron leakage upon in 🔗 External reference