Vibration Sensor/Detector Circuit

With the help of a simple ceramic piezoelectric detector, it is possible to assemble an interesting and useful impact sensor unit, which can be used to detect...

An impact sensor unit utilizing a ceramic piezoelectric detector operates by converting mechanical stress from an impact into an electrical signal. The ceramic piezoelectric material generates a voltage when subjected to deformation, making it an effective choice for detecting impacts in various applications.

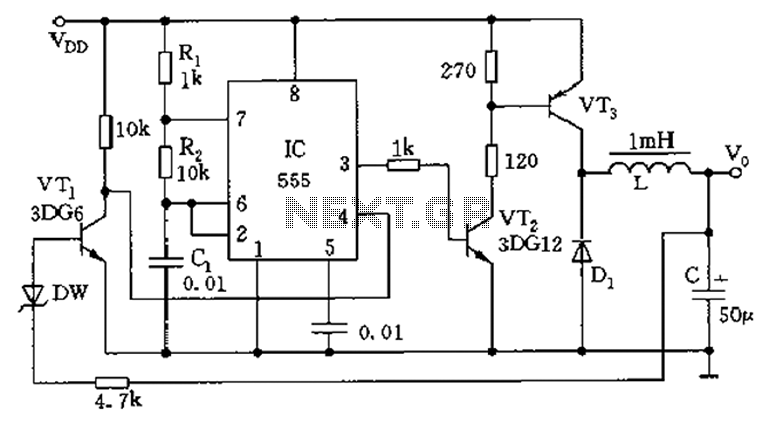

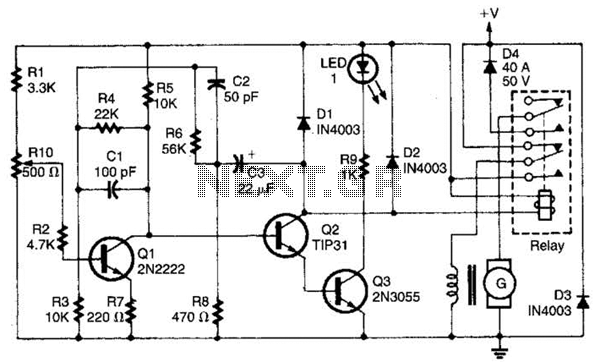

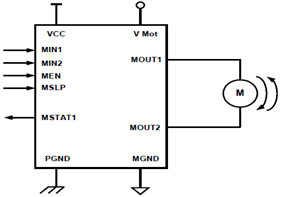

The circuit typically consists of the piezoelectric sensor connected in parallel with a resistor to form a voltage divider. This configuration allows for the monitoring of the voltage generated by the sensor when an impact occurs. The output can be further processed by an operational amplifier (op-amp) to enhance the signal strength, ensuring that even minor impacts can be detected.

For enhanced performance, a capacitor can be added in parallel with the resistor to filter out high-frequency noise, providing a cleaner signal. The output from the op-amp can be fed into a microcontroller or a comparator circuit, which can trigger an alert or perform an action based on the detected impact.

Power supply considerations are important; typically, a low-voltage DC supply is used to power the op-amp and any additional circuitry. The entire unit can be housed in a protective casing to ensure durability in various environments.

Applications for this impact sensor unit include monitoring structural integrity in buildings, detecting falls in elderly care systems, and providing security alerts in sensitive equipment. The simplicity and effectiveness of the piezoelectric impact sensor make it a valuable component in both commercial and industrial settings.With the help of a simple ceramic piezo-electric detector it is possible to assemble an interesting and useful Impact sensor unit,which can be used to dete.. 🔗 External reference

An impact sensor unit utilizing a ceramic piezoelectric detector operates by converting mechanical stress from an impact into an electrical signal. The ceramic piezoelectric material generates a voltage when subjected to deformation, making it an effective choice for detecting impacts in various applications.

The circuit typically consists of the piezoelectric sensor connected in parallel with a resistor to form a voltage divider. This configuration allows for the monitoring of the voltage generated by the sensor when an impact occurs. The output can be further processed by an operational amplifier (op-amp) to enhance the signal strength, ensuring that even minor impacts can be detected.

For enhanced performance, a capacitor can be added in parallel with the resistor to filter out high-frequency noise, providing a cleaner signal. The output from the op-amp can be fed into a microcontroller or a comparator circuit, which can trigger an alert or perform an action based on the detected impact.

Power supply considerations are important; typically, a low-voltage DC supply is used to power the op-amp and any additional circuitry. The entire unit can be housed in a protective casing to ensure durability in various environments.

Applications for this impact sensor unit include monitoring structural integrity in buildings, detecting falls in elderly care systems, and providing security alerts in sensitive equipment. The simplicity and effectiveness of the piezoelectric impact sensor make it a valuable component in both commercial and industrial settings.With the help of a simple ceramic piezo-electric detector it is possible to assemble an interesting and useful Impact sensor unit,which can be used to dete.. 🔗 External reference