Compass Detector

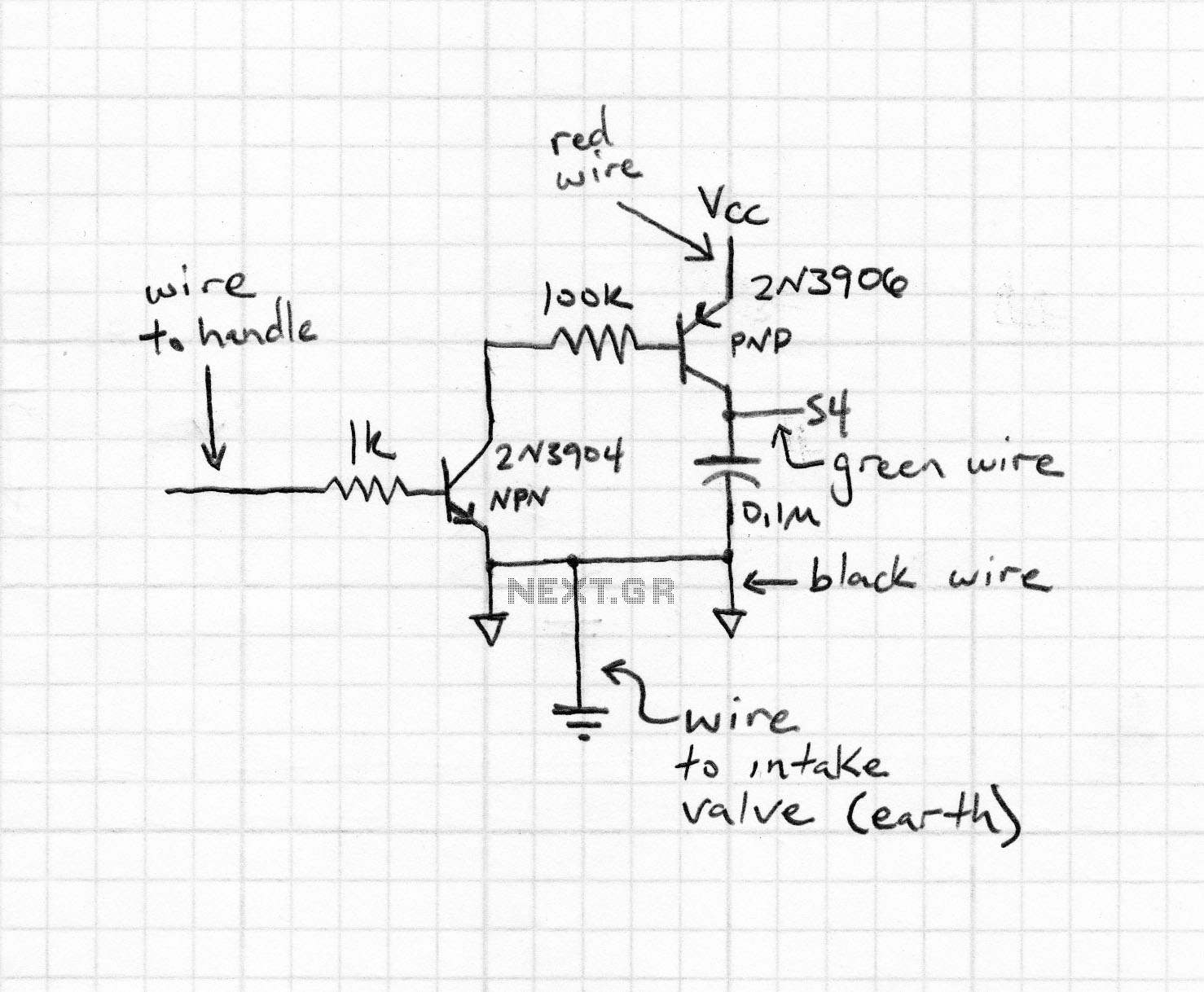

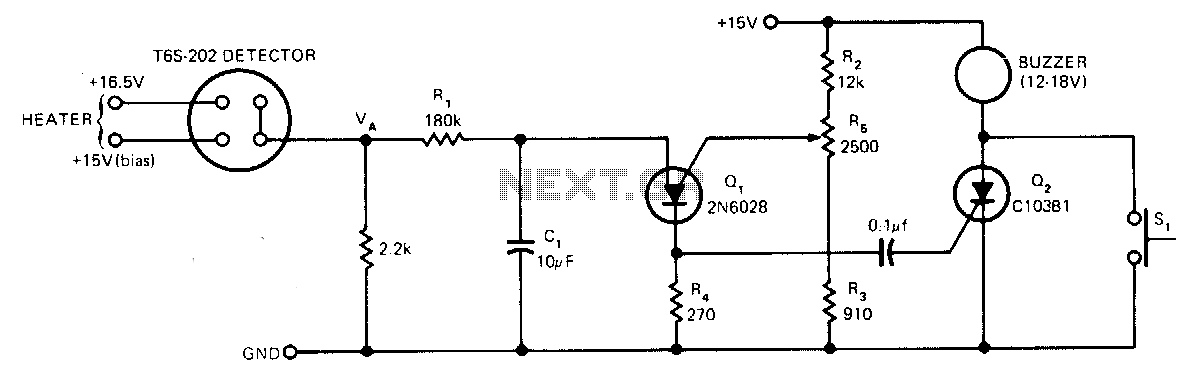

The LED phototransistor light gate should be mounted approximately 1 to 2 cm apart, within a rigid housing. It was mounted on a brass piece attached to the circuit board. The housing must accommodate the compass without obstructing the view of the needle, as it is necessary to observe the compass during setup. The suggested coil configuration consists of two coils arranged in parallel, with the diagonally opposite legs connected together, which is why there are two in the diagram. In the circuit used (as illustrated above), the collector of the phototransistor is connected to the zero rail, while the emitter is connected to pin 2 of the operational amplifier (op-amp). If the circuit does not function, reversing the connections may resolve the issue. Once the circuit is assembled and verified, the output (pin 6) should read approximately ±10 volts or higher when unobstructed, dropping to near zero volts when the light path is blocked. The next step is to align the coil and compass so that the needle blocks the light gate when pointing East-West, starting with the coil positioned about half a centimeter from the needle's end. Upon powering the circuit, the compass should slightly rotate towards the coil. If this does not occur, the coil's magnetic field may be aligned parallel to that of the compass, necessitating a rotation of the coil, switching the coil terminals, or repositioning the entire detector. As the needle begins to rotate, insert the soft iron into the coil slowly. The needle should move further until it aligns within the beam. Rapid insertion may cause the needle to bypass the beam, requiring a restart of the soft iron positioning. Monitoring the output voltage will reveal that as the iron is inserted, the output approaches zero volts, unless the needle exits the beam. Ideally, on a magnetically quiet day, the output voltage should stabilize near the midpoint of the output range, which should be noted for future reference. This setup should occur away from natural light, which can destabilize the detector. Once the needle is secured, it is possible to use a weakly magnetic object (e.g., a screwdriver) to reposition the needle back into the light gate when power is restored, ensuring the same end of the needle is used as during initial setup. No further adjustment of the soft iron should be necessary. Since overall light levels can influence circuit output, housing the circuit in a non-metallic box is recommended. It is also important to avoid placing the power supply or leads too close to the compass, and the measuring device should be positioned at least one meter away. If the op-amp output does not drop to zero when the light is blocked and instead fluctuates between positive and negative, the needle may not stabilize, which is likely due to the phototransistor being incorrectly oriented or another simple issue. The method of taking readings is flexible, as the measurement is simply a voltage. Systems capable of detecting small changes over large ranges are advantageous; however, for those without such capability, providing a reference voltage closer to the output measured during detector setup is advisable. This allows for easier measurement of small voltage changes. A 4.7 MΩ potentiometer (variable resistor) across the 15V power supply should suffice. The second two coils can operate independently for extended periods, while the first must be monitored similarly to the pop-bottle detector, with hourly checks until larger movements necessitate more frequent readings. For absolute comparisons (not generally recommended), consistency in reference voltage for the measuring device, the position of the soft iron, and the locations of nearby large metal objects is crucial. However, as long as the device is set up similarly for each measurement interval, comparing relative results (e.g., voltage changes rather than absolute voltages) is acceptable. The suggested values are functional, but actual outputs may vary due to component tolerances. When taking readings, it is essential to keep the detector as far from moving metal objects as possible, as they may disrupt measurements. This includes avoiding proximity to busy roads, railways, and elevators. The results page will provide insights into expected outcomes from the detector.The LED phototransistor light gate should be mounted about 1 to 2cm apart, in some kind of rigid housing. We mounted it on a piece of brass attached to the circuit board. The housing also needs to be able to fit the compass inside, and also not obscure the view of the needle, as you will need to be able to watch the compass while you are setting i

t up. The coil we have suggested is actually two coils and we used them set up in parallel to work with each other (the diagonally opposite legs should be connected together), which is why there are two in the diagram. In the circuit we used (and the diagram above) the collector of the phototransistor was connected to the zero rail, and the emitter was connected to pin 2 of the op-amp.

If your circuit does not work, try switching the legs over. When the circuit is built and double checked, then test the output of it (pin 6), it should be around (plus or minus) 10 volts or higher when there is nothing blocking the light, but drop to near zero volts when the path is blocked. Now you are ready for a test. Align the coil and the compass, so that the needle will block the light gate when it pointing East-West.

The coil should be about half a centimetre from the end of the needle to start with. Now switch on the circuit, and the compass should swing round towards the coil a little. If this does not happen the chances are that the coil`s magnetic field is parallel to that of the compass, to rectify this you can turn the coil around, or switch the terminals of the coil, or turn the whole detector around. Once the coil is making the needle rotate a little way you need to insert the soft iron into the coil, very slowly.

The needle should come further round until it is in the beam, where it should sit. If you do this too fast the needle will be able to come through the beam, and you will probably have to start the moving of the soft iron all over again. If you are monitoring the voltage of the output you will notice that the further in the coil the iron goes the nearer to zero the output gets (unless the needle leaves the beam all together).

Assuming that you are setting the detector up on a magnetically quiet day then you will want the output voltage to be somewhere near the middle of the output range. You might want to note this voltage for later. This should be performed away from natural light as this upsets the detector, and makes it too unstable to set up.

Once the needle has been caught and you switch off you should be able to use a weakly magnetic object (e. g. , a screwdriver) to place the needle back in the light gate when you turn it back on (remember to have the same end of the needle in the gate as when you set it up).

No further adjustment of the soft iron should be needed. As the overall light levels can affect the output of the circuit it is better to have the circuit in a box (not a metal box). Other things to watch out for are to not have the power supply or leads passing to close the the compass, and to have you measuring device a reasonable distance from the compass (1 metre or so should be fine).

Please note that if for some reason the output of the op-amp does not go to zero when the light is blocked, but instead changes from positive to negative (or vice versa), then the needle will not come to rest, and you should try and make sure that this does not happen, but it will probably only be down to having the phototransistor in the wrong way around, or something reasonably simple. How you take readings is up to you, as what you are measuring is just a voltage. Some systems can measure very small changes over large ranges, and these are great, but for those who don`t have this advantage you will want to provide a reference voltage much closer to the output that you measured when you set up the detector.

This means that instead of having to measure changes of hundredths of volts on a meter range of ten volts, you can measure them on a range of one for instance. A 4. 7MOhm potentiometer (variable resistor) across the 15V of the power supply should do the trick. The second two will run happily by themselves for long periods of time. The first will have to be monitored in much the same way as the pop-bottle detector, once an hour until the movements become larger when more frequent reading should be taken.

If absolute results are to be compared (not very advisable) then you must ensure that all things stay the same, reference voltage for the measuring device, position of soft iron piece, and positions of nearby large metal objects. However as long as the device is set up in a similar way for each period of measurement it is acceptable to compare relative results (i.

e. , not actual voltages, but voltage changes). The values suggested will work, but actual outputs may vary due to component tolerances. When taking readings it is important that the detector is as far from moving metal objects as possible as they will disturb it. This includes busy roads, railways, and lifts (elevators). The results page will give some idea of what might be expected from your detector. 🔗 External reference

t up. The coil we have suggested is actually two coils and we used them set up in parallel to work with each other (the diagonally opposite legs should be connected together), which is why there are two in the diagram. In the circuit we used (and the diagram above) the collector of the phototransistor was connected to the zero rail, and the emitter was connected to pin 2 of the op-amp.

If your circuit does not work, try switching the legs over. When the circuit is built and double checked, then test the output of it (pin 6), it should be around (plus or minus) 10 volts or higher when there is nothing blocking the light, but drop to near zero volts when the path is blocked. Now you are ready for a test. Align the coil and the compass, so that the needle will block the light gate when it pointing East-West.

The coil should be about half a centimetre from the end of the needle to start with. Now switch on the circuit, and the compass should swing round towards the coil a little. If this does not happen the chances are that the coil`s magnetic field is parallel to that of the compass, to rectify this you can turn the coil around, or switch the terminals of the coil, or turn the whole detector around. Once the coil is making the needle rotate a little way you need to insert the soft iron into the coil, very slowly.

The needle should come further round until it is in the beam, where it should sit. If you do this too fast the needle will be able to come through the beam, and you will probably have to start the moving of the soft iron all over again. If you are monitoring the voltage of the output you will notice that the further in the coil the iron goes the nearer to zero the output gets (unless the needle leaves the beam all together).

Assuming that you are setting the detector up on a magnetically quiet day then you will want the output voltage to be somewhere near the middle of the output range. You might want to note this voltage for later. This should be performed away from natural light as this upsets the detector, and makes it too unstable to set up.

Once the needle has been caught and you switch off you should be able to use a weakly magnetic object (e. g. , a screwdriver) to place the needle back in the light gate when you turn it back on (remember to have the same end of the needle in the gate as when you set it up).

No further adjustment of the soft iron should be needed. As the overall light levels can affect the output of the circuit it is better to have the circuit in a box (not a metal box). Other things to watch out for are to not have the power supply or leads passing to close the the compass, and to have you measuring device a reasonable distance from the compass (1 metre or so should be fine).

Please note that if for some reason the output of the op-amp does not go to zero when the light is blocked, but instead changes from positive to negative (or vice versa), then the needle will not come to rest, and you should try and make sure that this does not happen, but it will probably only be down to having the phototransistor in the wrong way around, or something reasonably simple. How you take readings is up to you, as what you are measuring is just a voltage. Some systems can measure very small changes over large ranges, and these are great, but for those who don`t have this advantage you will want to provide a reference voltage much closer to the output that you measured when you set up the detector.

This means that instead of having to measure changes of hundredths of volts on a meter range of ten volts, you can measure them on a range of one for instance. A 4. 7MOhm potentiometer (variable resistor) across the 15V of the power supply should do the trick. The second two will run happily by themselves for long periods of time. The first will have to be monitored in much the same way as the pop-bottle detector, once an hour until the movements become larger when more frequent reading should be taken.

If absolute results are to be compared (not very advisable) then you must ensure that all things stay the same, reference voltage for the measuring device, position of soft iron piece, and positions of nearby large metal objects. However as long as the device is set up in a similar way for each period of measurement it is acceptable to compare relative results (i.

e. , not actual voltages, but voltage changes). The values suggested will work, but actual outputs may vary due to component tolerances. When taking readings it is important that the detector is as far from moving metal objects as possible as they will disturb it. This includes busy roads, railways, and lifts (elevators). The results page will give some idea of what might be expected from your detector. 🔗 External reference