Control car horns in PWM

Past experiences were quite challenging due to the inductive nature of car horns, which require 12A of current, with peak demands reaching 20 to 30A. The current electronic system lacks reliability, given the high intensity. There is a need to dissipate 240W, which results in a temperature rise of 72°C (0.3 x 240), remaining below the maximum temperature threshold of 150°C, indicating potential operational viability. Additionally, consideration must be given to other thermal resistances, Rtheta HA and Rtheta CH. An electronic engineer advised that the voltage factor must be taken into account. If the voltage is halved to 6V, the MOSFET must dissipate: (12-6) * 20A = 120W. The worst-case scenario involves the MOSFET allowing only 0.0001V, leading to a dissipation of 240W. Utilizing PWM can manipulate the sound characteristics, including artifacts from material friction and sound distortion. The car horn's sound is characterized by saturation, and PWM can be used to modulate this sound akin to an ADSR envelope in music synthesis. Different envelopes yield various sounds. The electronic engineer also noted the importance of the voltage factor, reiterating that if the voltage is reduced to 6V, the MOSFET must handle a dissipation of 120W. The worst-case scenario, with the MOSFET allowing a minuscule voltage drop, results in 240W dissipation. There is uncertainty regarding the concepts of "linear" (Ohmic) and saturation (active) modes. According to sources, below a certain threshold, the MOSFET behaves like a resistor, and once active, its resistance is defined by Rdson. If the MOSFET is toggled on/off (5V / 0V) at a frequency of 500 times per second (PWM frequency), it operates below the threshold every 250 Hz, briefly acting as a resistor under a 12V current. It is unclear what occurs if only a 0 logic signal is sent via PWM. The MOSFET may never enter linear mode, leading to ambiguous conclusions. The relationship between PWM frequency and pitch remains uncertain. When similar techniques are applied to a speaker connected to a PWM output, pitch variations occur; however, control over the car horns is currently limited to volume adjustment.

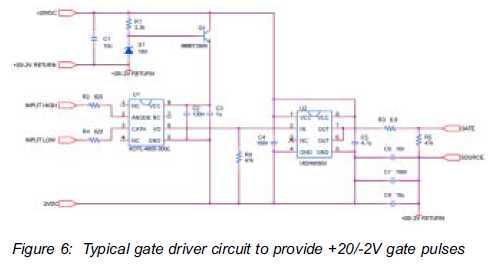

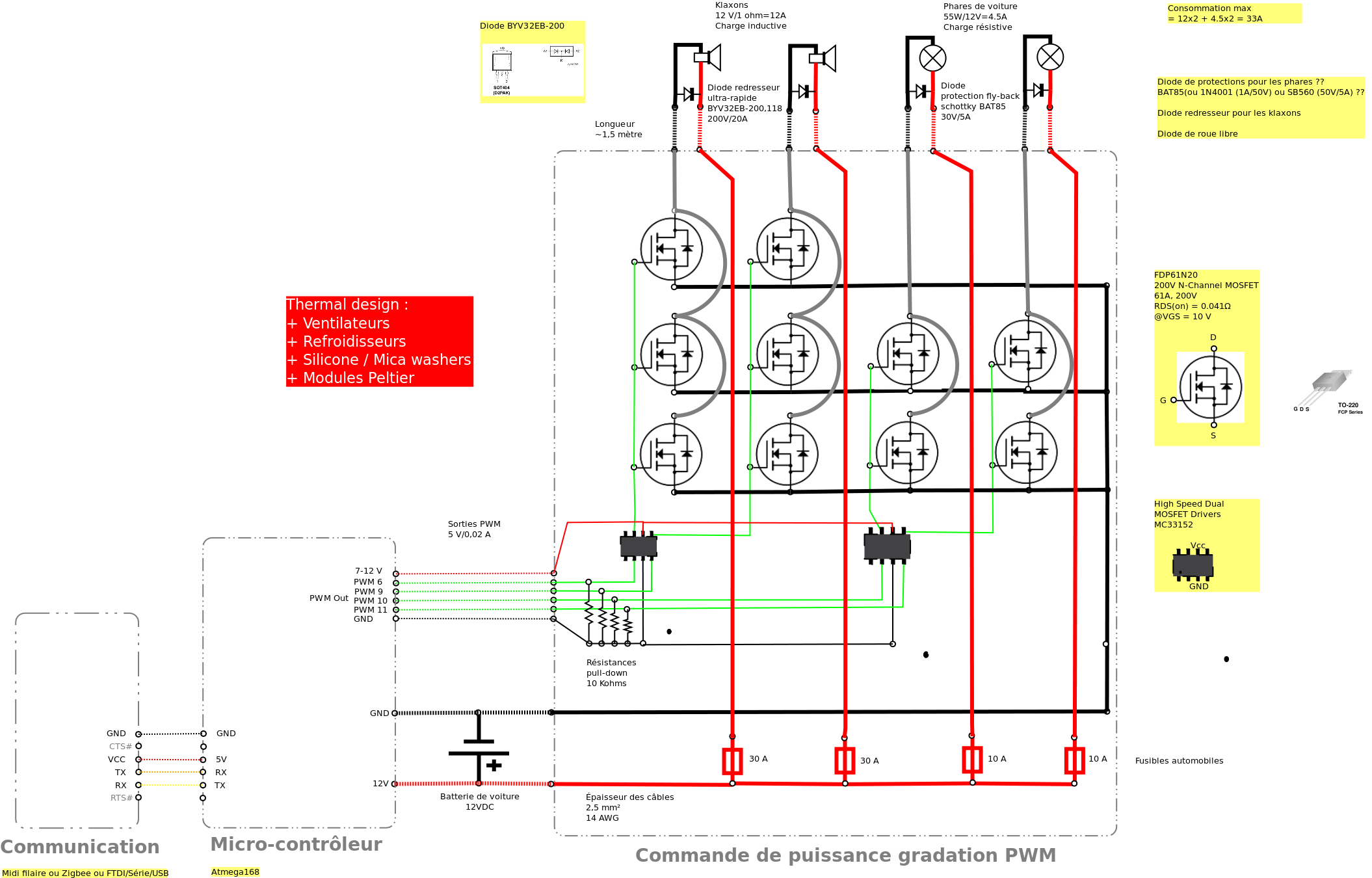

The circuit design involves a MOSFET driver capable of managing high current loads, specifically tailored for car horns. The MOSFET should be chosen based on its current rating, with a minimum threshold of 30A to accommodate peak demands. Thermal management is critical; therefore, a heatsink may be necessary to maintain operational temperatures within the specified limits. The PWM signal, generated by a microcontroller or dedicated PWM generator, modulates the gate of the MOSFET, allowing for precise control over the horn's volume and sound characteristics.

A snubber circuit, consisting of a resistor and capacitor in series, may be employed across the MOSFET to mitigate voltage spikes caused by the inductive load of the horn. This will enhance the reliability of the system and protect the MOSFET from potential damage. Additionally, the PWM frequency should be adjustable to explore the relationship between frequency and sound pitch, enabling further experimentation with sound modulation.

The circuit should also include a flyback diode in parallel with the horn to provide a path for the inductive kickback when the MOSFET is turned off, preventing damage to the MOSFET and ensuring system longevity. The overall design should prioritize efficiency, reliability, and thermal management to ensure optimal performance of the car horn system under varying operational conditions.The past experiences was pretty difficult, because the car horns have an inductive charge and it takes 12A and peak may be at 20 or 30A. The current electronic system is not reliable at all. It`s a lot of intensity. I need to dissipate 240W => 0. 3 x 240 = 72 °C. It is lesser than the temperature range maximum 150 °C, so it could work. Isn`t it Or I have to sum all other thermal resistances Rtheta HA and Rtheta CH An electronic engineer told me that I have to take the Volt factor. If I want to divide the voltage by 2 (6V), the MOSfet resists and has to dissipate : (12-6) * 20 A = 120 W.

That`s why I use the worst case, when the MOSfet resists to let pass only 0. 0001 V for example. It give me 240W. With PWM, you can play with the volume, some kind of artefacts (materials frictions) and sound distorsion (before and after). I realized that the car horn sound is the saturation. With PWM, I can play with this sound like an ADSR enveloppe in synthesis music. With differents enveloppes, we have different sounds. From : An electronic engineer told me that I have to take the Volt factor. If I want to divide the voltage by 2 (6V), the MOSfet resists and has to dissipate : (12-6) * 20 A = 120 W.

That`s why I use the worst case, when the MOSfet resists to let pass only 0. 0001 V for example. It give me 240W. I don`t know anything about "linear" (Ohmic) and saturation (active) modes. According to your note and the wikipedia article about MOSFET, it seems understable that below a threshold the mosfet acts like a resistor and after it is active, his resistance is equal to his Rdson. If I can put on/off (5V / 0V) the mosfet 500 times per second, the PWM frequency, it is below the threshold every 250 Hz, and it acts like a resistor very shortly, and with the 12V current.

And if I send in PWM only 0 logic signal, what happened. Is it a resistor May be the MOSfet is never in the linear mode, because. So I don`t know what conclude. I don`t know the relation between PWM frequency and the pitch. When you do the same thing with a speaker connected to a PWM output, you got pitch changing, but for now, I can`t control the horn horns, we control only the volume. 🔗 External reference

The circuit design involves a MOSFET driver capable of managing high current loads, specifically tailored for car horns. The MOSFET should be chosen based on its current rating, with a minimum threshold of 30A to accommodate peak demands. Thermal management is critical; therefore, a heatsink may be necessary to maintain operational temperatures within the specified limits. The PWM signal, generated by a microcontroller or dedicated PWM generator, modulates the gate of the MOSFET, allowing for precise control over the horn's volume and sound characteristics.

A snubber circuit, consisting of a resistor and capacitor in series, may be employed across the MOSFET to mitigate voltage spikes caused by the inductive load of the horn. This will enhance the reliability of the system and protect the MOSFET from potential damage. Additionally, the PWM frequency should be adjustable to explore the relationship between frequency and sound pitch, enabling further experimentation with sound modulation.

The circuit should also include a flyback diode in parallel with the horn to provide a path for the inductive kickback when the MOSFET is turned off, preventing damage to the MOSFET and ensuring system longevity. The overall design should prioritize efficiency, reliability, and thermal management to ensure optimal performance of the car horn system under varying operational conditions.The past experiences was pretty difficult, because the car horns have an inductive charge and it takes 12A and peak may be at 20 or 30A. The current electronic system is not reliable at all. It`s a lot of intensity. I need to dissipate 240W => 0. 3 x 240 = 72 °C. It is lesser than the temperature range maximum 150 °C, so it could work. Isn`t it Or I have to sum all other thermal resistances Rtheta HA and Rtheta CH An electronic engineer told me that I have to take the Volt factor. If I want to divide the voltage by 2 (6V), the MOSfet resists and has to dissipate : (12-6) * 20 A = 120 W.

That`s why I use the worst case, when the MOSfet resists to let pass only 0. 0001 V for example. It give me 240W. With PWM, you can play with the volume, some kind of artefacts (materials frictions) and sound distorsion (before and after). I realized that the car horn sound is the saturation. With PWM, I can play with this sound like an ADSR enveloppe in synthesis music. With differents enveloppes, we have different sounds. From : An electronic engineer told me that I have to take the Volt factor. If I want to divide the voltage by 2 (6V), the MOSfet resists and has to dissipate : (12-6) * 20 A = 120 W.

That`s why I use the worst case, when the MOSfet resists to let pass only 0. 0001 V for example. It give me 240W. I don`t know anything about "linear" (Ohmic) and saturation (active) modes. According to your note and the wikipedia article about MOSFET, it seems understable that below a threshold the mosfet acts like a resistor and after it is active, his resistance is equal to his Rdson. If I can put on/off (5V / 0V) the mosfet 500 times per second, the PWM frequency, it is below the threshold every 250 Hz, and it acts like a resistor very shortly, and with the 12V current.

And if I send in PWM only 0 logic signal, what happened. Is it a resistor May be the MOSfet is never in the linear mode, because. So I don`t know what conclude. I don`t know the relation between PWM frequency and the pitch. When you do the same thing with a speaker connected to a PWM output, you got pitch changing, but for now, I can`t control the horn horns, we control only the volume. 🔗 External reference