DC Motor Control

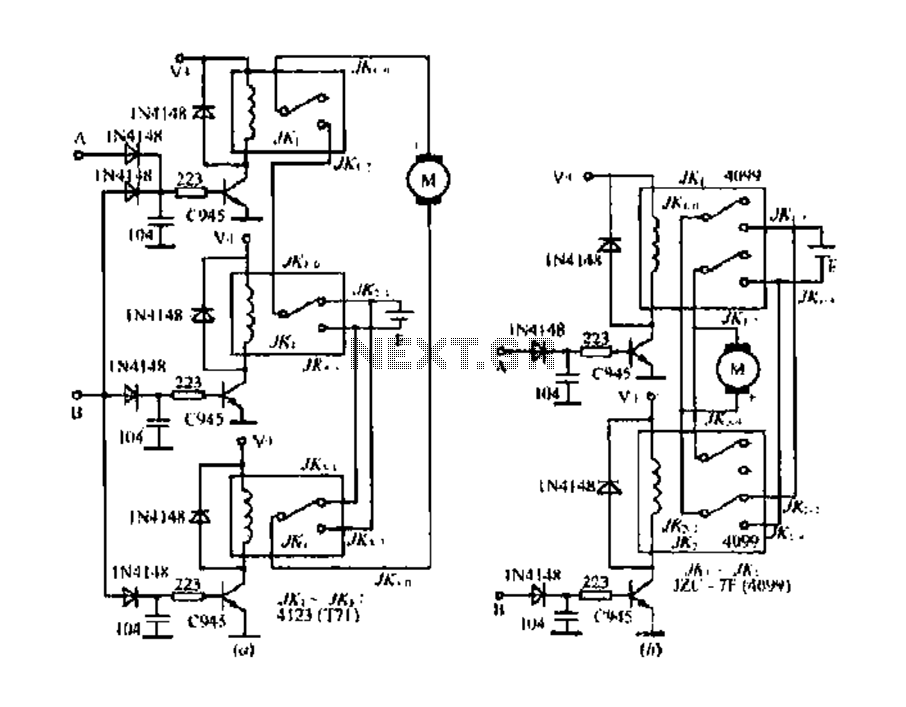

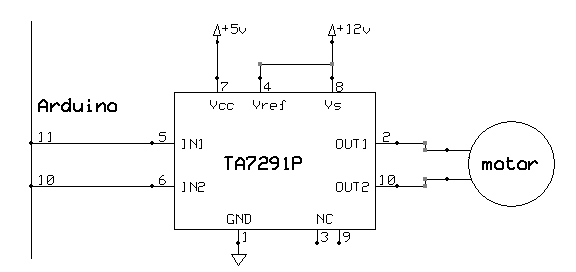

Buffer ICs (7417, 7414) were utilized to isolate the signals to and from the Arduino. This setup protected the board and provided power for external devices without drawing it from the Arduino. An H-bridge serves a similar purpose as it acts as the interface between an electrical signal and an electrical power source. Although they share the same medium, their functions are considerably different. The H-bridge is a common circuit employed to control the speed and direction of a DC motor using low current PWM signals. The specific H-bridge used is the TA7291P, which features a pair of half bridges capable of sourcing 1 Amp. DC motors are activated by applying voltage across their two terminals, with the rotation speed controlled by adjusting the applied voltage. The direction of motor rotation can be reversed by changing the polarity of the applied voltage. Half bridges enable control of both the speed and direction of DC motor rotation by acting as high power digital buffers; the output is 0V when the input is low and Vs when the input is high. To power a motor, half bridges can drive one terminal high while keeping the other low. Voltage control of the motor can be achieved by sending a PWM signal to one half bridge. For instance, if one bridge is held low and the other is driven high 50% of the time (with Vs=+12), the motor will function as if it were supplied with 6VDC. It is also possible to apply zero volts to the motor by driving both bridges low or both high. Some H-bridges have modes that induce a "coast to stop" condition (L-L for the TA7291P), while others provide a stronger "brake" stop. In this lab, only the digital output buffer and voltage follower will be used. Due to limited breadboard space, specific schematics must be implemented. Before proceeding with software tasks, it is essential to verify that the DC motor operates by supplying it with 5V from a benchtop power supply, as the Arduino cannot provide sufficient current. Connecting the DC motor directly to the 5V and GND may cause the board to shut down to prevent damage. The direction and speed of the DC motor can be controlled using a potentiometer, mimicking the throttle of a boat. When the potentiometer is fully turned to the right, the motor should spin rapidly in one direction. As the potentiometer is turned left, the motor should decelerate and eventually reverse direction. The motor's speed and direction should correspond to the potentiometer's rotation. The Arduino libraries provide a map function to scale values within a range, called by map(value, fromLow, fromHigh, toLow, toHigh). The parameters fromLow and fromHigh represent the initial value range, while toLow and toHigh represent the new value range. The function returns the scaled value. Velocity can be approximated as a change in position over time, which can be monitored using the millis() function in Arduino, returning the millisecond value of the onboard clock. The counter takes approximately 5 days to overflow and restart. Some H-bridges, like the LMD18200, have designated inputs for direction and speed (PWM). The most straightforward method of operation involves providing two input signals for direction and PWM. The LMD18200 is rated for 55V and 3 Amps and is available for checkout from the department. Simple PWM consists of a variable duty-cycle signal that encodes both direction and amplitude information. A 50% duty-cycle PWM signal indicates zero drive, as the net integrated voltage delivered to the load over one period is zero. A 25% duty-cycle PWM signal indicates current flow from OUT2 to OUT1, while a 75% duty-cycle signal indicates current flow in the opposite direction.

The circuit design incorporates buffer ICs to ensure signal integrity and protect the Arduino from potential overloads when interfacing with external devices. The TA7291P H-bridge is employed to facilitate motor control, allowing for both speed modulation and directional changes through the manipulation of PWM signals. The half-bridge design of the TA7291P simplifies the control of motor terminals, providing the ability to switch between high and low states effectively, which is essential for controlling the motor's operational characteristics.

The integration of a potentiometer into the system allows for intuitive user control, translating the physical position of the potentiometer into corresponding motor behavior. This setup mimics the functionality of a throttle, providing a dynamic response to user input. The use of the Arduino's map function enables precise scaling of the potentiometer's output to the desired motor speed and direction, enhancing the overall control and responsiveness of the system.

In summary, the combination of buffer ICs and the TA7291P H-bridge, along with the potentiometer interface, constitutes a robust and versatile solution for DC motor control, suitable for various applications requiring precise speed and direction management. The design emphasizes the importance of signal isolation and power management while maximizing the performance and reliability of the motor control system.We used buffer IC`s (7417, 7414) to isolate the signals to and from the Arduino. This protected the board, and provided power for external devices without drawing it from the Arduino. An H-bridge can be thought of in much the same way. It is the interface between an electrical signal and an electrical power source. Though they share thesame medium, their functions are vastly different. The H-bridge is a common circuit used to control the speed and direction of a DC motor with low current PWM signals. The H-bridge you will be using is the TA7291P ( datasheet ). It is a pair of half bridges that can source 1 Amp. DC motors are turned on by applying a voltage across the two terminals. The rotation speed can be controlled by increasing or decreasing the applied voltage. Changing the polarity of the applied voltage changes the motor`s direction of rotation. We can use half bridges to control both the speed and direction of rotation of a DC motor. Half bridges are essentially high power digital buffers; the output goes to 0V when the input is low, and the output goes to Vs when the input is high.

To power a motor, we can use half bridges to drive one terminal high and the other low. We also can control the voltage applied to the motor by sending one half bridge a PWM signal. For example, if we hold one bridge low and drive the other bridge high 50% of the time, (for Vs=+12) the motor will behave as if we applied 6VDC. Notice that we can apply zero volts to the motor by either driving both bridges low or both high. Some h-bridges are designed so that one of these modes puts the outputs in a "coast to stop" mode (L-L for the TA7291P); the other mode causes a stronger "brake" stop.

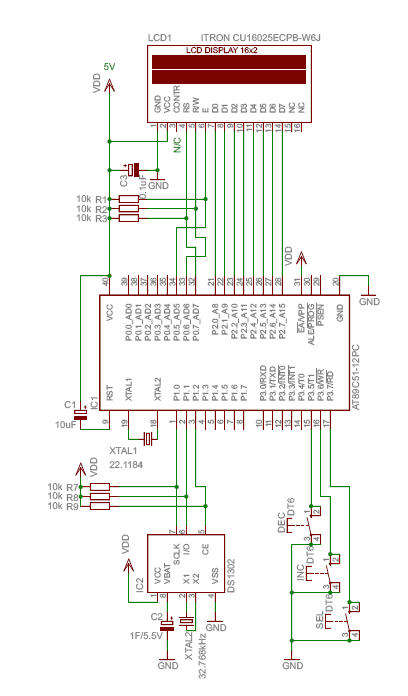

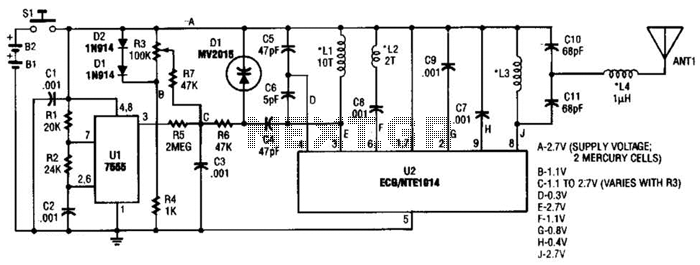

In this lab, you will be using only the digital output buffer and the voltage follower. As breadboard space is limited, these are the following schematics you should implement. Before you continue to the software tasks, make sure that your DC motor is working by supplying 5V from the benchtop power supply. The Arduino will not be able to supply enough current. Plugging the DC motor into the 5V and GND will trigger a board shutdown in order to prevent further damage.

Control the direction and speed of the provided DC motor with a potentiometer. The motor should behave like the throttle of a boat. A potentiometer twisted all the way to the right should have the motor spinning fast in one direction. As the potentiometer is twisted left, the motor should slow down and then begin spinning the other direction.

Tie the direction and speed of the motor spinning to the direction and speed of the potentiometer rotation. The faster you spin the potentiometer, the faster the motor should spin. The map function provided by the Arduino libraries provides an easy way to scale a number within a range.

It is called by map (value, fromLow, from High, toLow, toHigh). fromLow and fromHigh are the initial range of value. toLow and toHigh are the new range of values. The function returns the scaled value. Velocity can be approximated as a change in position over a change in time. You can keep track of time in the Arduino with the millis()function. millis() returns the millisecond value of the onboard clock. It takes about 5 days for this counter to run-over and restart. Some H-bridges, such as the LMD18200, simply have inputs for direction and speed (PWM). The most intuitive way of using them is to provide two input signals for direction and PWM. (The LMD18200 is rated for 55V, 3 Amps, and can be checked out from the department. ) Simple PWM consists of a single, variable duty-cycle signal in which both direction and amplitude information is encoded. A 50% duty-cycle PWM signal represents zero drive, since the net value of voltage (integrated over one period) delivered to the load is zero.

A 25% duty-cycle PWM signal represents current flow from OUT2 to OUT1 whereas a 75% duty-cycle represents current flow 🔗 External reference

The circuit design incorporates buffer ICs to ensure signal integrity and protect the Arduino from potential overloads when interfacing with external devices. The TA7291P H-bridge is employed to facilitate motor control, allowing for both speed modulation and directional changes through the manipulation of PWM signals. The half-bridge design of the TA7291P simplifies the control of motor terminals, providing the ability to switch between high and low states effectively, which is essential for controlling the motor's operational characteristics.

The integration of a potentiometer into the system allows for intuitive user control, translating the physical position of the potentiometer into corresponding motor behavior. This setup mimics the functionality of a throttle, providing a dynamic response to user input. The use of the Arduino's map function enables precise scaling of the potentiometer's output to the desired motor speed and direction, enhancing the overall control and responsiveness of the system.

In summary, the combination of buffer ICs and the TA7291P H-bridge, along with the potentiometer interface, constitutes a robust and versatile solution for DC motor control, suitable for various applications requiring precise speed and direction management. The design emphasizes the importance of signal isolation and power management while maximizing the performance and reliability of the motor control system.We used buffer IC`s (7417, 7414) to isolate the signals to and from the Arduino. This protected the board, and provided power for external devices without drawing it from the Arduino. An H-bridge can be thought of in much the same way. It is the interface between an electrical signal and an electrical power source. Though they share thesame medium, their functions are vastly different. The H-bridge is a common circuit used to control the speed and direction of a DC motor with low current PWM signals. The H-bridge you will be using is the TA7291P ( datasheet ). It is a pair of half bridges that can source 1 Amp. DC motors are turned on by applying a voltage across the two terminals. The rotation speed can be controlled by increasing or decreasing the applied voltage. Changing the polarity of the applied voltage changes the motor`s direction of rotation. We can use half bridges to control both the speed and direction of rotation of a DC motor. Half bridges are essentially high power digital buffers; the output goes to 0V when the input is low, and the output goes to Vs when the input is high.

To power a motor, we can use half bridges to drive one terminal high and the other low. We also can control the voltage applied to the motor by sending one half bridge a PWM signal. For example, if we hold one bridge low and drive the other bridge high 50% of the time, (for Vs=+12) the motor will behave as if we applied 6VDC. Notice that we can apply zero volts to the motor by either driving both bridges low or both high. Some h-bridges are designed so that one of these modes puts the outputs in a "coast to stop" mode (L-L for the TA7291P); the other mode causes a stronger "brake" stop.

In this lab, you will be using only the digital output buffer and the voltage follower. As breadboard space is limited, these are the following schematics you should implement. Before you continue to the software tasks, make sure that your DC motor is working by supplying 5V from the benchtop power supply. The Arduino will not be able to supply enough current. Plugging the DC motor into the 5V and GND will trigger a board shutdown in order to prevent further damage.

Control the direction and speed of the provided DC motor with a potentiometer. The motor should behave like the throttle of a boat. A potentiometer twisted all the way to the right should have the motor spinning fast in one direction. As the potentiometer is twisted left, the motor should slow down and then begin spinning the other direction.

Tie the direction and speed of the motor spinning to the direction and speed of the potentiometer rotation. The faster you spin the potentiometer, the faster the motor should spin. The map function provided by the Arduino libraries provides an easy way to scale a number within a range.

It is called by map (value, fromLow, from High, toLow, toHigh). fromLow and fromHigh are the initial range of value. toLow and toHigh are the new range of values. The function returns the scaled value. Velocity can be approximated as a change in position over a change in time. You can keep track of time in the Arduino with the millis()function. millis() returns the millisecond value of the onboard clock. It takes about 5 days for this counter to run-over and restart. Some H-bridges, such as the LMD18200, simply have inputs for direction and speed (PWM). The most intuitive way of using them is to provide two input signals for direction and PWM. (The LMD18200 is rated for 55V, 3 Amps, and can be checked out from the department. ) Simple PWM consists of a single, variable duty-cycle signal in which both direction and amplitude information is encoded. A 50% duty-cycle PWM signal represents zero drive, since the net value of voltage (integrated over one period) delivered to the load is zero.

A 25% duty-cycle PWM signal represents current flow from OUT2 to OUT1 whereas a 75% duty-cycle represents current flow 🔗 External reference