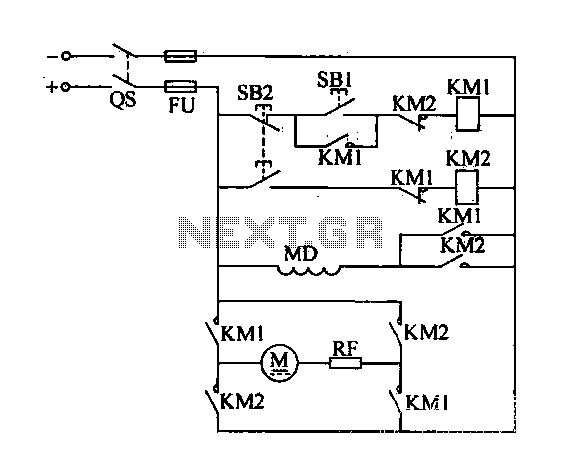

DC motor reverse brake circuit

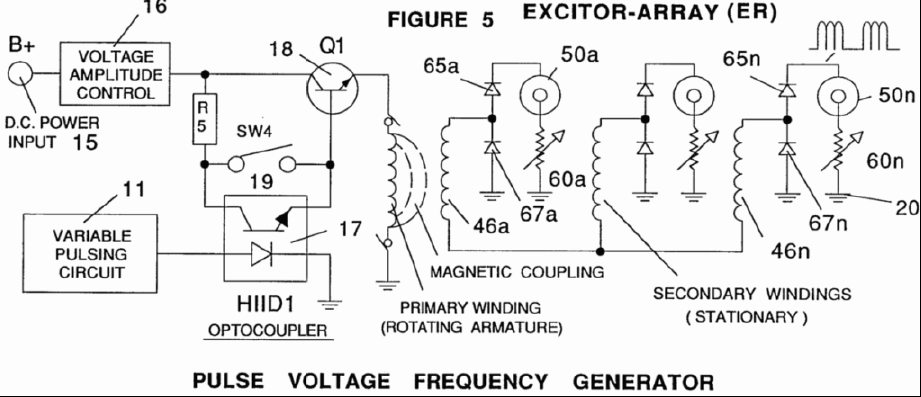

A DC motor reverse brake circuit is presented. To initiate braking, the stop button (SB2) is pressed, which disconnects the move-off contact, causing KM1 to lose power and release. Subsequently, the brake contactor (KM2) is activated. KM2 is designed for electric operation, reversing the armature power. As a result, the motor's electromagnetic torque transitions into braking torque, leading to a rapid decrease in motor speed until it approaches zero. Releasing the stop button (SB2) concludes the braking process.

The DC motor reverse brake circuit is an essential configuration used in applications requiring rapid deceleration of the motor. The operation of this circuit begins with the pressing of the stop button (SB2), which interrupts the power supply to the move-off contact. This action results in the deactivation of contactor KM1, effectively disconnecting the motor from its power source.

Once KM1 is released, the brake contactor KM2 is energized. This contactor is specifically designed to reverse the armature voltage applied to the motor. When KM2 is activated, it causes the motor's electromagnetic torque to switch from its normal operational mode to a braking mode. This transition is crucial as it generates a braking torque that opposes the motor's rotation, leading to a swift reduction in the motor's speed.

The braking process continues until the motor speed drops to a near-zero value. This rapid deceleration is vital in applications where precise control over motor speed is necessary, such as in conveyor systems or robotic actuators. Once the desired speed is achieved, releasing the stop button (SB2) completes the braking sequence, allowing the motor to remain in a stationary state until further commands are issued.

Key components of this circuit include the DC motor, the move-off contact, contactor KM1, and the brake contactor KM2. The design ensures that the transition from normal operation to braking is smooth and efficient, minimizing wear on the motor and associated mechanical components. Proper implementation of this circuit can enhance the overall safety and reliability of motor-driven systems.DC motor reverse brake circuit is shown. Braking, press the stop button SB2, disconnect move off contact so KM1 loss of power release, then turned on the brake contactor KM2 ci rcuit. KM2 eligible for electric operation, the armature power reverse, the motor electromagnetic torque becomes braking torque, the motor speed rapidly drops to near zero, release the stop button SB2, the end of the braking process.

The DC motor reverse brake circuit is an essential configuration used in applications requiring rapid deceleration of the motor. The operation of this circuit begins with the pressing of the stop button (SB2), which interrupts the power supply to the move-off contact. This action results in the deactivation of contactor KM1, effectively disconnecting the motor from its power source.

Once KM1 is released, the brake contactor KM2 is energized. This contactor is specifically designed to reverse the armature voltage applied to the motor. When KM2 is activated, it causes the motor's electromagnetic torque to switch from its normal operational mode to a braking mode. This transition is crucial as it generates a braking torque that opposes the motor's rotation, leading to a swift reduction in the motor's speed.

The braking process continues until the motor speed drops to a near-zero value. This rapid deceleration is vital in applications where precise control over motor speed is necessary, such as in conveyor systems or robotic actuators. Once the desired speed is achieved, releasing the stop button (SB2) completes the braking sequence, allowing the motor to remain in a stationary state until further commands are issued.

Key components of this circuit include the DC motor, the move-off contact, contactor KM1, and the brake contactor KM2. The design ensures that the transition from normal operation to braking is smooth and efficient, minimizing wear on the motor and associated mechanical components. Proper implementation of this circuit can enhance the overall safety and reliability of motor-driven systems.DC motor reverse brake circuit is shown. Braking, press the stop button SB2, disconnect move off contact so KM1 loss of power release, then turned on the brake contactor KM2 ci rcuit. KM2 eligible for electric operation, the armature power reverse, the motor electromagnetic torque becomes braking torque, the motor speed rapidly drops to near zero, release the stop button SB2, the end of the braking process.