DC MOTOR SPEED CONTROL

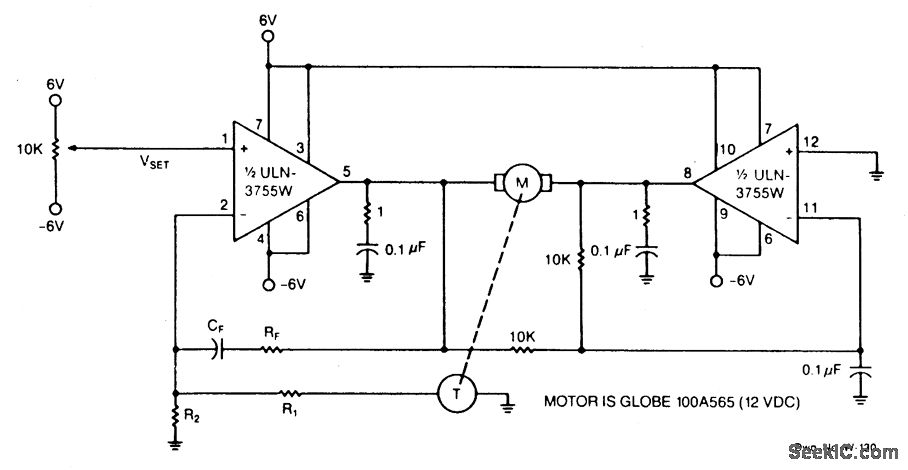

Power operational amplifiers provide precise speed control for DC motors. The circuit enables bidirectional speed control. The amplifiers' push-pull configuration guarantees a full rail-to-rail voltage swing (excluding the saturation drops of the output stages) across the motor in both directions. A mechanically-coupled tachometer is utilized to deliver speed-stabilizing feedback to the first amplifier section. The motor's speed and direction of rotation are adjusted by varying the 10 k ohm potentiometer at the non-inverting input of the amplifier. The RFCF feedback network prevents oscillation by compensating for the motor's inherent dynamic mechanical lag. The RFCF time constant should be selected to align with the specific characteristics of the motor.

Power operational amplifiers are integral components in circuits designed for precise control of DC motor speed and direction. In this configuration, the circuit employs a push-pull amplifier setup, which allows for a complete voltage swing across the motor terminals. This is critical for achieving the desired performance in both forward and reverse motor operations, as it ensures that the motor receives the necessary voltage to overcome its internal resistance and any load it may be driving.

The inclusion of a mechanically-coupled tachometer serves a pivotal role in providing real-time feedback regarding the motor's speed. This feedback is essential for maintaining stable operation, particularly in applications where speed consistency is crucial. The tachometer outputs a voltage proportional to the motor's speed, which is fed back to the amplifier's input, enabling closed-loop control. This mechanism allows for dynamic adjustments to the input signal, ensuring that the motor speed remains within the desired range.

The adjustment of motor speed and direction is facilitated by a 10 k ohm potentiometer connected to the non-inverting input of the first amplifier. By varying the resistance, the user can finely tune the input voltage, thereby controlling the output signal that drives the motor. This feature is particularly useful in applications requiring a high degree of control over motor performance.

To enhance stability and prevent oscillations in the system, the RFCF feedback network is implemented. This network is designed to compensate for the dynamic mechanical lag that occurs in motors, which can lead to instability if not properly managed. The RFCF time constant is a critical parameter that must be selected based on the specific characteristics of the motor being used. It is essential to analyze the motor's response to ensure that the feedback loop remains stable and responsive, thereby optimizing the overall performance of the speed control circuit. Proper tuning of this time constant is vital for achieving a smooth and reliable motor operation across varying load conditions.Power op amps provide accurate speed control for dc motors. The circuit provides bidirectional speed control. The amplifiers` push-pull configuration ensures a full rail-to-rail voltage swing (minus the output stages` saturation drops) across the motor in either direction. The circuit uses a mechanically-coupled tachometer to provide speed-stabili zing feedback to the first amplifier section. The motor`s speed and direction of rotation is set by adjusting the 10 k ohm potentiometer at the amplifier`s noninverting input. The RFCF feedback network prevents oscillation by compensating for the inherent dynamic mechanical lag of the motor.

Select the RFCF time constant to match the particular motor`s characteristics. 🔗 External reference

Power operational amplifiers are integral components in circuits designed for precise control of DC motor speed and direction. In this configuration, the circuit employs a push-pull amplifier setup, which allows for a complete voltage swing across the motor terminals. This is critical for achieving the desired performance in both forward and reverse motor operations, as it ensures that the motor receives the necessary voltage to overcome its internal resistance and any load it may be driving.

The inclusion of a mechanically-coupled tachometer serves a pivotal role in providing real-time feedback regarding the motor's speed. This feedback is essential for maintaining stable operation, particularly in applications where speed consistency is crucial. The tachometer outputs a voltage proportional to the motor's speed, which is fed back to the amplifier's input, enabling closed-loop control. This mechanism allows for dynamic adjustments to the input signal, ensuring that the motor speed remains within the desired range.

The adjustment of motor speed and direction is facilitated by a 10 k ohm potentiometer connected to the non-inverting input of the first amplifier. By varying the resistance, the user can finely tune the input voltage, thereby controlling the output signal that drives the motor. This feature is particularly useful in applications requiring a high degree of control over motor performance.

To enhance stability and prevent oscillations in the system, the RFCF feedback network is implemented. This network is designed to compensate for the dynamic mechanical lag that occurs in motors, which can lead to instability if not properly managed. The RFCF time constant is a critical parameter that must be selected based on the specific characteristics of the motor being used. It is essential to analyze the motor's response to ensure that the feedback loop remains stable and responsive, thereby optimizing the overall performance of the speed control circuit. Proper tuning of this time constant is vital for achieving a smooth and reliable motor operation across varying load conditions.Power op amps provide accurate speed control for dc motors. The circuit provides bidirectional speed control. The amplifiers` push-pull configuration ensures a full rail-to-rail voltage swing (minus the output stages` saturation drops) across the motor in either direction. The circuit uses a mechanically-coupled tachometer to provide speed-stabili zing feedback to the first amplifier section. The motor`s speed and direction of rotation is set by adjusting the 10 k ohm potentiometer at the amplifier`s noninverting input. The RFCF feedback network prevents oscillation by compensating for the inherent dynamic mechanical lag of the motor.

Select the RFCF time constant to match the particular motor`s characteristics. 🔗 External reference