DEFROST TIMER CIRCUITS SCHEMATIC DIAGRAM

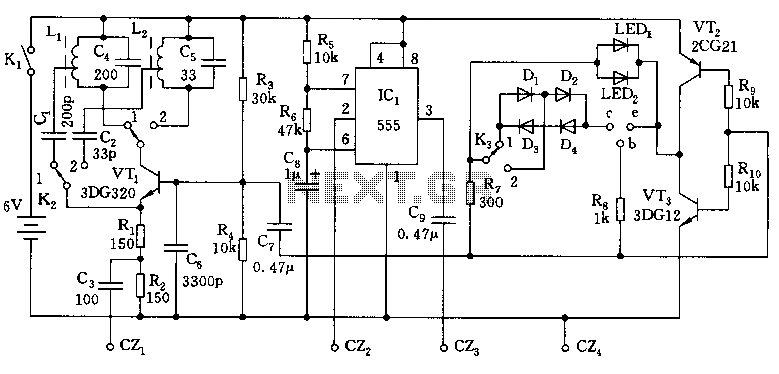

The purpose of this timer is to disconnect the compressor circuit and connect a resistive heating element located near the evaporator at regular time intervals. The defrost heater is controlled by a thermostat and is used to melt any frost that forms on the evaporator. The defrost heater operates for a specified duration before the timer disconnects it from the circuit, allowing the compressor to function again. The defrost timer is driven by a single-phase synchronous motor, similar to those used in electric wall clocks. The contacts are activated by a cam that is gear-driven by the clock motor. A schematic diagram of the timer illustrates that terminal 1 is connected to the common of a single-pole double-throw switch, while terminals 2 and 4 connect to the stationary contacts of the switch. In normal operation, the switch connects contacts 1 and 4. When the defrost cycle is activated, the contact shifts to connect terminals 1 and 2. Terminal 3 connects to one lead of the motor, while the other motor lead exits the case. It is important to note that the schematic can be misleading; it shows that the timer contact can only connect terminals 1 and 4, or terminals 1 and 2. However, a common issue with this timer is that the movable contact can become stuck between terminals 4 and 2, resulting in simultaneous operation of the compressor and defrost heater. The schematic for the continuous run timer indicates that the motor's pigtail lead connects to terminal 1, which is directly linked to the power source, while terminal 3 connects to neutral. This configuration allows the timer motor to operate continuously. The operation of the timer during the compressor run cycle shows a current path through the timer motor and to the thermostat, enabling power to the compressor and evaporator motor when the thermostat closes. When the timer activates the defrost cycle, the current path remains intact through the timer motor, but the circuit to the thermostat opens, and the circuit to the defrost heater closes, allowing the heater to melt frost on the evaporator. At the end of the defrost cycle, the timer contact returns to its normal position, allowing the thermostat to operate the compressor. The cumulative compressor run timer circuit derives its name from the fact that the timer motor operates only when the compressor is running and the thermostat is closed. The schematic for this circuit shows the clock motor's pigtail lead connected to terminal 2. During compressor operation, the timer contact connects terminals 1 and 4, applying power to the thermostat. When the thermostat closes, current flows through the compressor motor, evaporator fan motor, and defrost timer motor. In this configuration, the timer motor is in series with the defrost heater, but its operation is not affected due to its higher impedance compared to the heater's resistance, ensuring that most of the voltage drops across the timer motor and limiting current flow.

The timer circuit is designed to manage the operation of the compressor and defrost heater effectively. The single-phase synchronous motor provides reliable timing, ensuring the defrost cycle occurs at appropriate intervals. The use of a single-pole double-throw switch allows for seamless switching between the compressor and defrost heater, although care must be taken to avoid mechanical issues that could lead to simultaneous operation.

The schematic representation is critical for understanding the connections and operation of the timer. Each terminal's function is clearly defined, with terminal 1 serving as the common point for the switch, facilitating the transition between defrost and compressor modes. The continuous run timer variant demonstrates a more direct connection to the power source, allowing for uninterrupted operation of the timer motor, which is vital for maintaining the proper timing of the defrost cycles.

The operation of the timer is crucial in preventing ice buildup on the evaporator, which can impair system efficiency. By accurately controlling the defrost heater's operation, the timer ensures that the evaporator remains functional and that the compressor can operate effectively when needed. The design considerations, including the impedance of the timer motor, play a significant role in maintaining the integrity of the circuit and ensuring reliable performance. Overall, this timer circuit is an essential component in refrigeration systems, balancing the need for effective defrosting with the operational requirements of the compressor.The job of this timer is to disconnect thecompressor circuit and connect a resistive heatingelement located near the evaporator atregular time intervals. The defrost heater is thermostaticallycontrolled and is used to melt any frostformation on the evaporator.

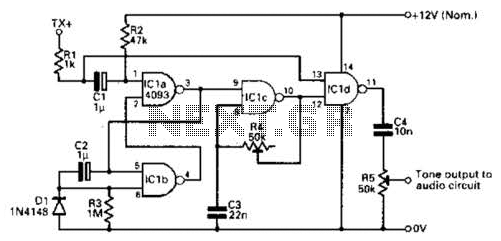

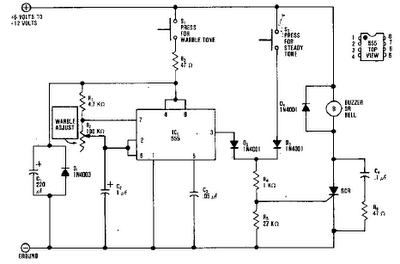

The defrost heater ispermitted to operate for some length of time beforethe timer disconnects it from the circuit and permitsthe compressor to operate again. The defrost timer is operated by a single-phase synchronousmotor like those used to operate electricwall clocks, Figure 28 1. The contacts are operatedby a cam that is gear driven by the clock motor. A schematic drawing of the timer is shown inFigure 28 2. Notice that terminal 1 is connected tothe common of a single-pole double-throw switch. Terminals 2 and 4 are connected to stationary contactsof the switch. In the normal operating mode, the switch makes connection between contacts1 and 4. When the defrost cycle is activated, thecontact will change position and make connectionbetween terminals 1 and 2.

Terminal 3 is connectedto one lead of the motor. The other motor lead isbrought outside the case. It should be noted that the schematic drawingcan be a little misleading. In the schematicshown, the timer contact can only make connectionbetween terminals 1 and 4, or terminals 1 and 2. Inactual practice, a common problem with this timeris that the movable contact becomes stuck betweenterminals 4 and 2.

This causes the compressor anddefrost heater to operate at the same time. The schematic for the continuous run timer isshown in Figure 28 3. Notice in this circuit that thepigtail lead of the motor has been connected to terminal1, and that terminal 1 is connected directly tothe power source. Terminal 3 is connected directlyto the neutral. This places the timer motor directlyacross the power source, which permits the motor tooperate on a continuous basis.

Figure 28 4 shows the operation of the timer inthe compressor run cycle. Notice there is a currentpath through the timer motor and a path throughthe timer contact to the thermostat. This permitspower to be applied to the compressor and evaporatormotor when the thermostat closes. Figure 28 5 shows the operation of the circuitwhen the timer changes the contact and activates thedefrost cycle.

Notice there is still a complete circuitthrough the timer motor. When the timer contactchanges position, the circuit to the thermostat is openand the circuit to the defrost heater is closed. Theheater can now melt any frost accumulation on theevaporator. At the end of the defrost cycle, the timercontact returns to its normal position and permits thecompressor to be operated by the thermostat.

The cumulative compressor run timer circuit gets itsname from the fact that the timer motor is permittedto operate only when the compressor is in operationand the thermostat is closed. The schematic for thiscircuit is shown in Figure 28 6. Notice that thepigtail lead of the clock motor has been connected toterminal 2 instead of terminal 1.

Figure 28 7 showsthe current path during compressor operation. Thetimer contact is making connection between terminals1 and 4. This permits power to be appliedto the thermostat. When the thermostat contactcloses, current is permitted to fl ow through thecompressor motor, the evaporator fan motor, andthe defrost timer motor. In this circuit, the timermotor is connected in series with the defrost heater. The operation of the timer motor is not affected, however, because the impedance of the timer motoris much greater than the resistance of the heater.

For this reason almost all the voltage of this circuitis dropped across the timer motor. The impedance ofthe timer motor also limits the current fl ow 🔗 External reference

The timer circuit is designed to manage the operation of the compressor and defrost heater effectively. The single-phase synchronous motor provides reliable timing, ensuring the defrost cycle occurs at appropriate intervals. The use of a single-pole double-throw switch allows for seamless switching between the compressor and defrost heater, although care must be taken to avoid mechanical issues that could lead to simultaneous operation.

The schematic representation is critical for understanding the connections and operation of the timer. Each terminal's function is clearly defined, with terminal 1 serving as the common point for the switch, facilitating the transition between defrost and compressor modes. The continuous run timer variant demonstrates a more direct connection to the power source, allowing for uninterrupted operation of the timer motor, which is vital for maintaining the proper timing of the defrost cycles.

The operation of the timer is crucial in preventing ice buildup on the evaporator, which can impair system efficiency. By accurately controlling the defrost heater's operation, the timer ensures that the evaporator remains functional and that the compressor can operate effectively when needed. The design considerations, including the impedance of the timer motor, play a significant role in maintaining the integrity of the circuit and ensuring reliable performance. Overall, this timer circuit is an essential component in refrigeration systems, balancing the need for effective defrosting with the operational requirements of the compressor.The job of this timer is to disconnect thecompressor circuit and connect a resistive heatingelement located near the evaporator atregular time intervals. The defrost heater is thermostaticallycontrolled and is used to melt any frostformation on the evaporator.

The defrost heater ispermitted to operate for some length of time beforethe timer disconnects it from the circuit and permitsthe compressor to operate again. The defrost timer is operated by a single-phase synchronousmotor like those used to operate electricwall clocks, Figure 28 1. The contacts are operatedby a cam that is gear driven by the clock motor. A schematic drawing of the timer is shown inFigure 28 2. Notice that terminal 1 is connected tothe common of a single-pole double-throw switch. Terminals 2 and 4 are connected to stationary contactsof the switch. In the normal operating mode, the switch makes connection between contacts1 and 4. When the defrost cycle is activated, thecontact will change position and make connectionbetween terminals 1 and 2.

Terminal 3 is connectedto one lead of the motor. The other motor lead isbrought outside the case. It should be noted that the schematic drawingcan be a little misleading. In the schematicshown, the timer contact can only make connectionbetween terminals 1 and 4, or terminals 1 and 2. Inactual practice, a common problem with this timeris that the movable contact becomes stuck betweenterminals 4 and 2.

This causes the compressor anddefrost heater to operate at the same time. The schematic for the continuous run timer isshown in Figure 28 3. Notice in this circuit that thepigtail lead of the motor has been connected to terminal1, and that terminal 1 is connected directly tothe power source. Terminal 3 is connected directlyto the neutral. This places the timer motor directlyacross the power source, which permits the motor tooperate on a continuous basis.

Figure 28 4 shows the operation of the timer inthe compressor run cycle. Notice there is a currentpath through the timer motor and a path throughthe timer contact to the thermostat. This permitspower to be applied to the compressor and evaporatormotor when the thermostat closes. Figure 28 5 shows the operation of the circuitwhen the timer changes the contact and activates thedefrost cycle.

Notice there is still a complete circuitthrough the timer motor. When the timer contactchanges position, the circuit to the thermostat is openand the circuit to the defrost heater is closed. Theheater can now melt any frost accumulation on theevaporator. At the end of the defrost cycle, the timercontact returns to its normal position and permits thecompressor to be operated by the thermostat.

The cumulative compressor run timer circuit gets itsname from the fact that the timer motor is permittedto operate only when the compressor is in operationand the thermostat is closed. The schematic for thiscircuit is shown in Figure 28 6. Notice that thepigtail lead of the clock motor has been connected toterminal 2 instead of terminal 1.

Figure 28 7 showsthe current path during compressor operation. Thetimer contact is making connection between terminals1 and 4. This permits power to be appliedto the thermostat. When the thermostat contactcloses, current is permitted to fl ow through thecompressor motor, the evaporator fan motor, andthe defrost timer motor. In this circuit, the timermotor is connected in series with the defrost heater. The operation of the timer motor is not affected, however, because the impedance of the timer motoris much greater than the resistance of the heater.

For this reason almost all the voltage of this circuitis dropped across the timer motor. The impedance ofthe timer motor also limits the current fl ow 🔗 External reference