digital clock circuit diagram

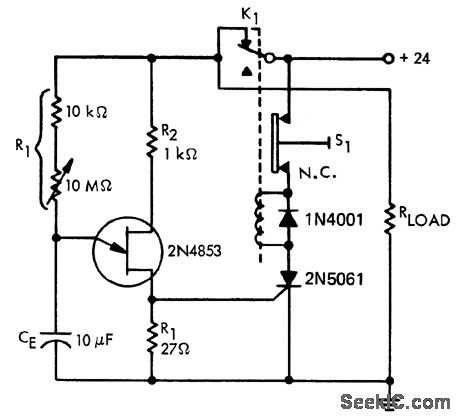

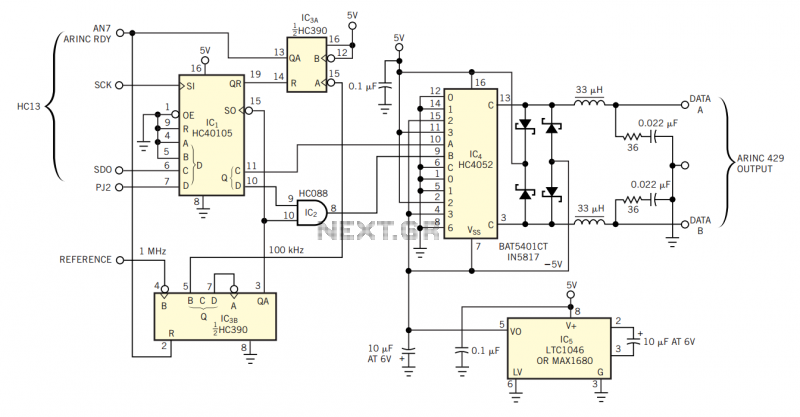

This device is a combination digital clock timer and solar panel charge controller designed to maintain a deep cycle battery from a solar panel. The timer output controls a 12-volt load for a 32-minute interval each day. The start time is configured using nine dip switches and concludes 32 minutes later. The duration is determined by selecting the fifth bit of a 4040 binary counter (pin 2). Additionally, the timer features a manual toggle switch to enable or disable the load, automatically shutting off after the 32-minute period. The time duration can be adjusted to longer or shorter intervals (8, 16, 32, 64, 128, 256 minutes, etc.) by selecting the appropriate bit of the counter. The timer circuit is depicted in the lower schematic above the regulator. The basic clock circuit (top schematic below) resembles a binary clock and utilizes seven integrated circuits (ICs) to generate 20 digital bits for 12-hour time, including AM and PM indicators. A standard 32,768 Hz watch crystal oscillator serves as the time base, which is divided down to half a second using the 4020 binary counter. One half of a 4013 data latch divides the half-second signal by two, producing a one-second pulse that drives the seconds counter (74HC390, colored purple). The minutes are advanced by decoding 60 seconds (40 + 20) and resetting the seconds counter to zero while simultaneously advancing the minutes counter. A similar procedure is followed to advance the hours. The second half of the 4013 latch indicates AM or PM and toggles upon decoding 13 hours, resetting the hours to zero and advancing to "one." The clock display circuit, shown in the second drawing below, employs six additional ICs to decode binary data and drive four seven-segment LED displays. The tens of hours digit is driven by a single 3904 transistor. Two multiplexer circuits (4053) allow for the manual selection of either minutes or seconds for the right two display digits. The two switches between the 4053s and below the left 4053 are part of a single DPDT switch that selects either seconds or minutes for the 1X and 10X digits. This switch is depicted in the seconds position, while the hours digits are blanked with a low signal on pin 4 of the 4511. The display can also be toggled on and off (completely blank) using a set/reset latch constructed from a couple of 74HC00 NAND gates. A momentary DPDT switch controls the latch to toggle the display on or off. The second pole of this switch is utilized in the upper drawing (connected to the run/stop switch) for setting hours and minutes, allowing the same switch to perform both functions of blanking the display and adjusting the time. The run/stop switch is shown in normal operation mode, supplying a low signal to a NAND gate to prevent accidental time setting while the clock is running. This switch also activates the display (through diode D2) when in the stop position. To set the clock, the run/stop switch should be placed in the stop position, and the seconds/minutes switch set to the minutes position. The momentary switch is then toggled to set the current time's minutes and hours, plus one minute. The clock can be started with the run/stop switch at the precise time (± 0.5 seconds). The voltage regulator in the lower drawing maintains the battery at 13.6 volts and supplies the clock and timer circuits with 4.3 volts. The charge LED indicator activates only when the regulator delivers maximum charge to the battery. When the battery voltage reaches 13.6 volts, the regulator reduces current to maintain this voltage, causing the charge indicator to turn off. The constructed unit also includes a battery condition indicator (voltmeter using four LEDs) to show battery status, ensuring that a failure of the regulator is indicated by the charge indicator LED turning off and fewer than four LEDs lighting on the voltmeter.

The digital clock timer and solar panel charge controller circuit integrates several key functionalities. The timer's ability to control a 12-volt load for a predetermined duration is critical for applications where energy management is essential, such as in remote solar-powered systems. The use of a 4040 binary counter allows for flexible timing options, providing versatility in energy consumption.

The clock circuitry utilizes a standard crystal oscillator, ensuring accurate timekeeping, while the binary counting approach simplifies the design and minimizes component count. The cascading of counters and latches allows for efficient time representation and display management. The use of multiplexers to toggle between display modes enhances user interaction, allowing for intuitive adjustments.

The voltage regulation aspect of the circuit is vital for maintaining battery health, preventing overcharging, and ensuring that the connected load receives stable voltage. The inclusion of a visual battery condition indicator improves system reliability by providing real-time feedback on battery status, thus facilitating proactive maintenance.

Overall, this combination device not only serves as a reliable timekeeping solution but also enhances the efficiency of solar energy utilization, making it suitable for various applications in renewable energy systems.This is a combination digital clock timer and solar panel charge controller used to maintain a deep cycle battery from a solar panel. The timer output is used to control a 12 volt load for a 32 minute time interval each day. Start time is set using 9 dip switches and ends 32 minutes later. The 32 minute duration is set by selecting the 5th bit of a 4040 binary counter (pin 2). The timer also has a manual toggle switch so the load can be manually switched on or off and automatically shuts off after 32 minutes. The time duration can be longer or shorter (8, 16, 32, 64, 128, 256 minutes etc. ) by selecting the appropriate bit of the counter. The timer circuit is shown in the lower schematic just above the regulator. The basic clock circuit (top schematic below) is similar to the binary clock (on another page) and uses 7 ICs to produce the 20 digital bits for 12 hour time, plus AM and PM.

A standard watch crystal oscillator (32, 768) is used as the time base and is divided down to 1/2 half second by the 4020 binary counter. One half of a 4013 data latch is used to divide the 1/2 second signal by 2 and produce a one second pulse that drives the seconds counter (74HC390 colored purple).

The minutes are advanced by decoding 60 seconds (40 + 20) and then resetting the seconds counter to 0 and at the same time advancing the minutes counter. The same procedure is used to advance the hours. The second half of the 4013 latch is used to indicate AM or PM and is toggled by decoding 13 hours and resetting the hours to 0 and then advancing the hours to "one".

The clock display circuit is shown in the second drawing below and uses 6 more ICs to decode the binary data and drive four seven segment LED displays. The 10s of hours digit is driven with a single 3904 transistor. Two multiplexer circuits (4053) are used to manually select either minutes or seconds for the right two display digits.

The two switches shown between the 4053s and below the left 4053 are both part of one DPDT switch which selects either seconds or minutes for the 1X and 10X digits. This switch is shown in the seconds position and the hours digits are blanked with a low signal on pin 4 of the 4511.

The display can also be toggled on and off (totally blank) using a set/reset latch made from a couple 74HC00 NAND gates. A momentary DPDT switch is used to control the latch and toggle the display on or off. The second pole of this switch is used on the upper drawing (connected to the run/stop switch) to set the hours and minutes.

Thus this same switch performs both functions of blanking the display and setting the time. The run/stop switch is shown in the normal running mode and supplies a low signal to a NAND gate which prevents accidental setting the time while the clock is running. The run/stop switch also turns on the display (through the diode D2) when in the stop position. The procedure for setting the clock would be to set the (run/stop) switch the stop position and the (seconds/minutes) switch to the minutes position.

Then toggle the momentary switch to set minutes and hours of the current time plus one minute. The clock can then be started with the run/stop switch at precisely the right time (+/- 0. 5 seconds). The voltage regulator in the lower drawing maintains the battery at 13. 6 volts and also supplies the clock and timer circuits with 4. 3 volts. The charge LED indicator only comes on when the regulator is supplying max charge to the battery. When the battery voltage reaches 13. 6 the regulator reduces the current to whatever is necessary to maintain the voltage and the charge indicator will turn off. The unit I built also included a battery condition indicator (voltmeter using 4 LEDs) to indicate the battery condition so that a failure of the regulator would be indicated by the charge indicator LED turned off and less than 4 LEDs lit on the voltmeter.

🔗 External reference

The digital clock timer and solar panel charge controller circuit integrates several key functionalities. The timer's ability to control a 12-volt load for a predetermined duration is critical for applications where energy management is essential, such as in remote solar-powered systems. The use of a 4040 binary counter allows for flexible timing options, providing versatility in energy consumption.

The clock circuitry utilizes a standard crystal oscillator, ensuring accurate timekeeping, while the binary counting approach simplifies the design and minimizes component count. The cascading of counters and latches allows for efficient time representation and display management. The use of multiplexers to toggle between display modes enhances user interaction, allowing for intuitive adjustments.

The voltage regulation aspect of the circuit is vital for maintaining battery health, preventing overcharging, and ensuring that the connected load receives stable voltage. The inclusion of a visual battery condition indicator improves system reliability by providing real-time feedback on battery status, thus facilitating proactive maintenance.

Overall, this combination device not only serves as a reliable timekeeping solution but also enhances the efficiency of solar energy utilization, making it suitable for various applications in renewable energy systems.This is a combination digital clock timer and solar panel charge controller used to maintain a deep cycle battery from a solar panel. The timer output is used to control a 12 volt load for a 32 minute time interval each day. Start time is set using 9 dip switches and ends 32 minutes later. The 32 minute duration is set by selecting the 5th bit of a 4040 binary counter (pin 2). The timer also has a manual toggle switch so the load can be manually switched on or off and automatically shuts off after 32 minutes. The time duration can be longer or shorter (8, 16, 32, 64, 128, 256 minutes etc. ) by selecting the appropriate bit of the counter. The timer circuit is shown in the lower schematic just above the regulator. The basic clock circuit (top schematic below) is similar to the binary clock (on another page) and uses 7 ICs to produce the 20 digital bits for 12 hour time, plus AM and PM.

A standard watch crystal oscillator (32, 768) is used as the time base and is divided down to 1/2 half second by the 4020 binary counter. One half of a 4013 data latch is used to divide the 1/2 second signal by 2 and produce a one second pulse that drives the seconds counter (74HC390 colored purple).

The minutes are advanced by decoding 60 seconds (40 + 20) and then resetting the seconds counter to 0 and at the same time advancing the minutes counter. The same procedure is used to advance the hours. The second half of the 4013 latch is used to indicate AM or PM and is toggled by decoding 13 hours and resetting the hours to 0 and then advancing the hours to "one".

The clock display circuit is shown in the second drawing below and uses 6 more ICs to decode the binary data and drive four seven segment LED displays. The 10s of hours digit is driven with a single 3904 transistor. Two multiplexer circuits (4053) are used to manually select either minutes or seconds for the right two display digits.

The two switches shown between the 4053s and below the left 4053 are both part of one DPDT switch which selects either seconds or minutes for the 1X and 10X digits. This switch is shown in the seconds position and the hours digits are blanked with a low signal on pin 4 of the 4511.

The display can also be toggled on and off (totally blank) using a set/reset latch made from a couple 74HC00 NAND gates. A momentary DPDT switch is used to control the latch and toggle the display on or off. The second pole of this switch is used on the upper drawing (connected to the run/stop switch) to set the hours and minutes.

Thus this same switch performs both functions of blanking the display and setting the time. The run/stop switch is shown in the normal running mode and supplies a low signal to a NAND gate which prevents accidental setting the time while the clock is running. The run/stop switch also turns on the display (through the diode D2) when in the stop position. The procedure for setting the clock would be to set the (run/stop) switch the stop position and the (seconds/minutes) switch to the minutes position.

Then toggle the momentary switch to set minutes and hours of the current time plus one minute. The clock can then be started with the run/stop switch at precisely the right time (+/- 0. 5 seconds). The voltage regulator in the lower drawing maintains the battery at 13. 6 volts and also supplies the clock and timer circuits with 4. 3 volts. The charge LED indicator only comes on when the regulator is supplying max charge to the battery. When the battery voltage reaches 13. 6 the regulator reduces the current to whatever is necessary to maintain the voltage and the charge indicator will turn off. The unit I built also included a battery condition indicator (voltmeter using 4 LEDs) to indicate the battery condition so that a failure of the regulator would be indicated by the charge indicator LED turned off and less than 4 LEDs lit on the voltmeter.

🔗 External reference