Dimming the Nixies

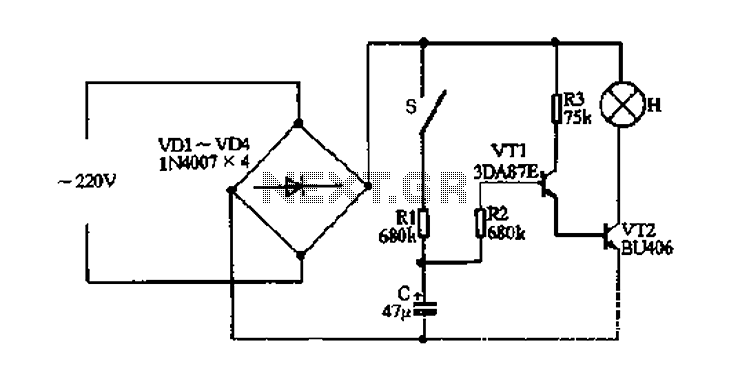

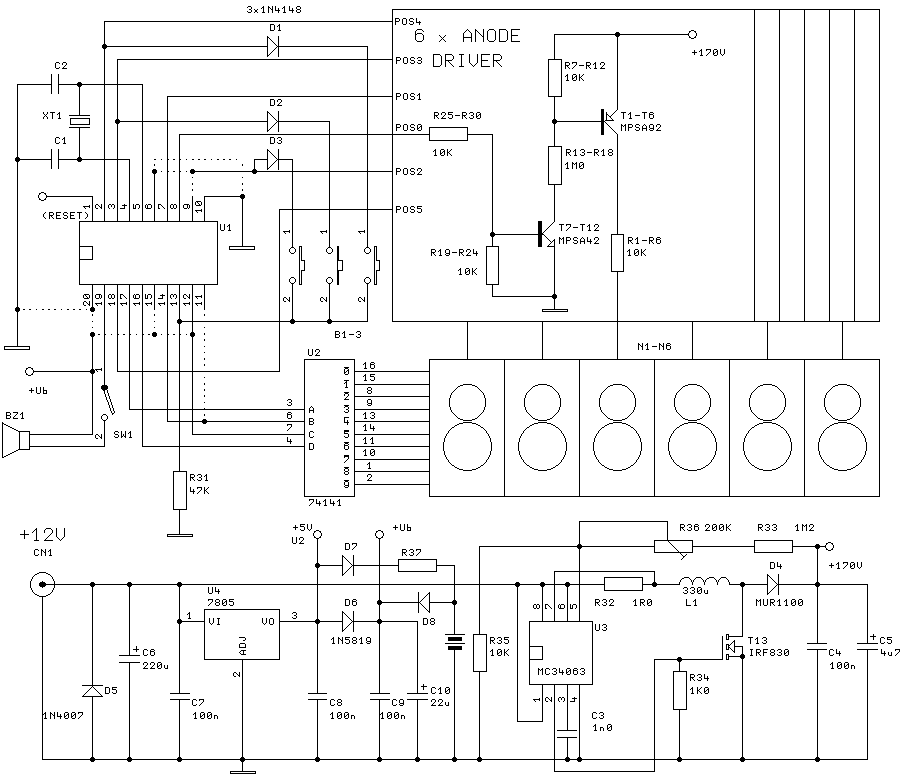

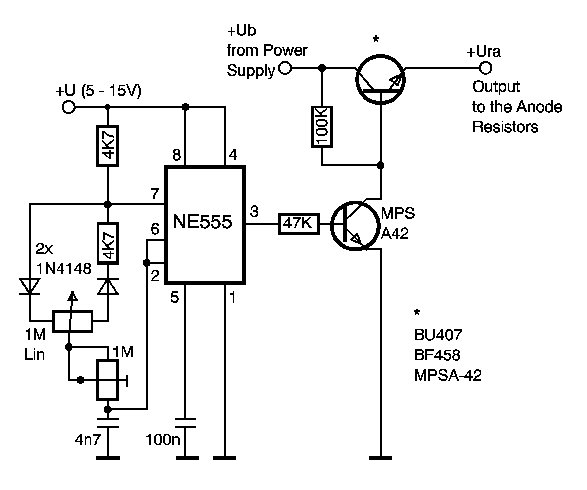

Nixie tubes require a specific cathode current to illuminate the cathode completely. Reducing the anode voltage leads to a decrease in current through the anode resistor, which also reduces the cathode current. This can result in the cathode being only partially illuminated or not lighting up at all, which is undesirable. A more complex approach is proposed, which is said to yield better results than merely lowering the anode voltage. The circuit features a simple oscillator using a 555 timer chip, with a notable inclusion of a 1M Ohm potentiometer and two diodes. This configuration allows for the adjustment of the duty cycle of the output signal between 5% and 95%. A transistor is connected to the high voltage supply line between the power supply and the Nixie anode resistors. The 555 timer drives another transistor that controls the base voltage of the main transistor. As a result, a lower duty cycle from the 555 output signal increases the conductive time of the main transistor, allowing full current to flow through the anode resistors. The circuit operates by switching high voltage rather than regulating it. The component values enable frequency variations between approximately 3 ms to 8.5 ms (about 117 Hz to 330 Hz), with optimal performance at around 3.5 ms (285 Hz) for ZM1080 tubes. The duty cycle regulation ranges from 5% to 95%, where 95% results in a dim but readable glow with fully illuminated cathodes. High voltage transistors are necessary due to their connection to the high voltage supply or their role in sinking the base voltage of the main transistor. The BU-407 was selected as the main transistor for the prototype, although smaller alternatives like the BF-458 or MPSA-42 may suffice for fewer tubes. While this circuit has limitations, it performs significantly better than merely reducing anode voltage and current, which cannot be decreased below a certain threshold. A simple potentiometer can be used to adjust intensity without requiring isolation or uncommon values. However, the circuit's complexity prevents the use of a photo-transistor for automatic intensity regulation, which would necessitate additional components. Consideration has been given to using dual FETs and an inverter stage for this purpose. If a "flashing dot" neon light has already been dimmed with a higher anode resistor, it may fail to operate effectively at lower brightness levels or may flash erratically.

The described circuit effectively manages the illumination of Nixie tubes by employing a 555 timer oscillator to control the duty cycle of the output signal. The use of a potentiometer allows for fine-tuning of the brightness, accommodating the specific needs of the Nixie tubes in use. The high voltage switching approach not only enhances the performance of the tubes but also avoids the limitations associated with simply lowering the anode voltage. The choice of transistors is critical; they must be rated for high voltage to handle the demands of the circuit while ensuring reliable operation.

The frequency adjustment capability of the circuit allows for flexibility in performance, making it suitable for various applications involving Nixie tubes. The duty cycle regulation from 5% to 95% provides a wide range of brightness settings, enabling users to achieve the desired level of illumination. This feature is particularly beneficial in scenarios where visibility under different lighting conditions is necessary.

Future enhancements could include the integration of automatic intensity regulation using photo-transistors or alternative components to adapt to ambient light changes. This would require additional circuitry, possibly involving dual FETs and an inverter stage, to create a more sophisticated control mechanism. Overall, the circuit presents a robust solution for effectively driving Nixie tubes while maintaining their operational integrity and visual appeal.Fact is that the Nixies need a particular cathode current to entirely light up the cathode at all. If you just reduce the anode voltage the current through the anode resistor drops and so does the cathode current. Up to a certain point where the cathode is only partially covered with the discharge glow - or doesn`t come on at all.

Both is not what we wanted, right So here is my approach that is a bit more complicated but seems to work fine. At least for my taste better than just reducing the anode voltage. Your individual mileage may vary however. The circuit shown above is a simple oscillator with a 555 chip. The only uncommon part of the layout is the 1M Ohm Potentiometer and the two diodes. This part of the circuit allows to vary the duty-cycle of the output signal between 5 and 95 percent. The transistor in the upper part is wired into the high voltage supply line between power supply and the nixie anode resistors.

The 555 is driving another transistor that simply cuts off the voltage on the base of that "main" transistor. Result: the lower the duty cycle of the 555 output signal, the longer is the conductive period of the main transistor - during which the full current flows through the anode resistors.

The trick is, that the high voltage is switched and not regulated. The component values in the schematic allow a frequency variation between 3 - 8. 5 ms (about 117 - 330 Hz) and the best results with a set of ZM1080s is at about 3. 5 ms (285 Hz). Here the regulation of the duty cycle works from 5 to 95 %, where 95% is pretty dim, but still readable and the cathodes fully covered. The transistors must be any of the high voltage types, since it is either attached to the HV-supply or has to sink the base voltage of the main transistor.

For my prototype I picked a BU-407 as main transistor, because I had it at hand. You might come away with an even smaller one like the BF-458 or even one MPSA-42, if you don`t have 6 x ZM1040 or bigger tubes running. This circuit has its limitations of course, but it works far better than just reducing the anode voltage and current, which cannot be reduced below a certain point.

You can use a simple potentiometer with all pins at low voltage levels to set the intensity. No need to pick something isolated or something of very uncommon value. Apart from the "high complexity" you cannot use e. g. a photo-transistor for automatic regulation (dark outside = low intensity) or such. This will require some more parts. I thought about dual FETs and an inverter stage probably. I`m open for ideas here. (Grin !) If you have a "flashing dot" neon and reduced its intensity with a higher anode resistor already it may fail to operate below a certain dimming. Or flash erratically. 🔗 External reference

The described circuit effectively manages the illumination of Nixie tubes by employing a 555 timer oscillator to control the duty cycle of the output signal. The use of a potentiometer allows for fine-tuning of the brightness, accommodating the specific needs of the Nixie tubes in use. The high voltage switching approach not only enhances the performance of the tubes but also avoids the limitations associated with simply lowering the anode voltage. The choice of transistors is critical; they must be rated for high voltage to handle the demands of the circuit while ensuring reliable operation.

The frequency adjustment capability of the circuit allows for flexibility in performance, making it suitable for various applications involving Nixie tubes. The duty cycle regulation from 5% to 95% provides a wide range of brightness settings, enabling users to achieve the desired level of illumination. This feature is particularly beneficial in scenarios where visibility under different lighting conditions is necessary.

Future enhancements could include the integration of automatic intensity regulation using photo-transistors or alternative components to adapt to ambient light changes. This would require additional circuitry, possibly involving dual FETs and an inverter stage, to create a more sophisticated control mechanism. Overall, the circuit presents a robust solution for effectively driving Nixie tubes while maintaining their operational integrity and visual appeal.Fact is that the Nixies need a particular cathode current to entirely light up the cathode at all. If you just reduce the anode voltage the current through the anode resistor drops and so does the cathode current. Up to a certain point where the cathode is only partially covered with the discharge glow - or doesn`t come on at all.

Both is not what we wanted, right So here is my approach that is a bit more complicated but seems to work fine. At least for my taste better than just reducing the anode voltage. Your individual mileage may vary however. The circuit shown above is a simple oscillator with a 555 chip. The only uncommon part of the layout is the 1M Ohm Potentiometer and the two diodes. This part of the circuit allows to vary the duty-cycle of the output signal between 5 and 95 percent. The transistor in the upper part is wired into the high voltage supply line between power supply and the nixie anode resistors.

The 555 is driving another transistor that simply cuts off the voltage on the base of that "main" transistor. Result: the lower the duty cycle of the 555 output signal, the longer is the conductive period of the main transistor - during which the full current flows through the anode resistors.

The trick is, that the high voltage is switched and not regulated. The component values in the schematic allow a frequency variation between 3 - 8. 5 ms (about 117 - 330 Hz) and the best results with a set of ZM1080s is at about 3. 5 ms (285 Hz). Here the regulation of the duty cycle works from 5 to 95 %, where 95% is pretty dim, but still readable and the cathodes fully covered. The transistors must be any of the high voltage types, since it is either attached to the HV-supply or has to sink the base voltage of the main transistor.

For my prototype I picked a BU-407 as main transistor, because I had it at hand. You might come away with an even smaller one like the BF-458 or even one MPSA-42, if you don`t have 6 x ZM1040 or bigger tubes running. This circuit has its limitations of course, but it works far better than just reducing the anode voltage and current, which cannot be reduced below a certain point.

You can use a simple potentiometer with all pins at low voltage levels to set the intensity. No need to pick something isolated or something of very uncommon value. Apart from the "high complexity" you cannot use e. g. a photo-transistor for automatic regulation (dark outside = low intensity) or such. This will require some more parts. I thought about dual FETs and an inverter stage probably. I`m open for ideas here. (Grin !) If you have a "flashing dot" neon and reduced its intensity with a higher anode resistor already it may fail to operate below a certain dimming. Or flash erratically. 🔗 External reference