Electric thermos temperature detection control circuit

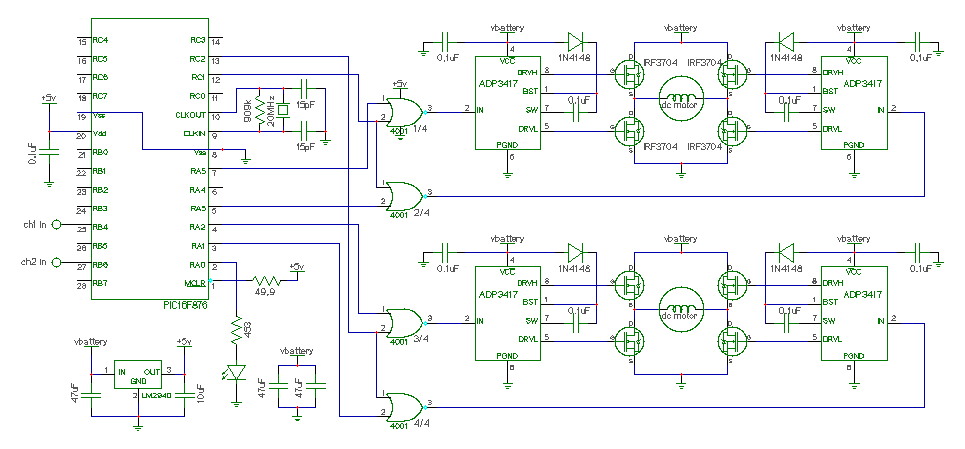

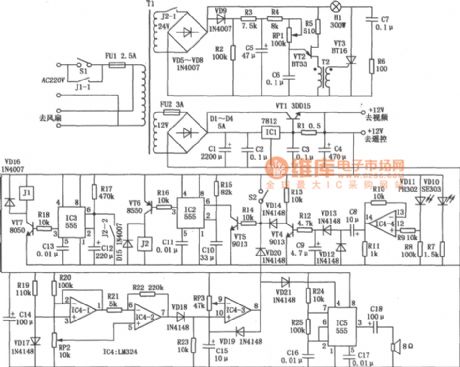

The electric thermos temperature detection control circuit is designed to monitor and manage the temperature within an electric thermos. It primarily consists of a control circuit for the boiler heater and heater insulation, an electrical magnetic pump motor drive circuit, and a configuration for the heating and warming light circuit.

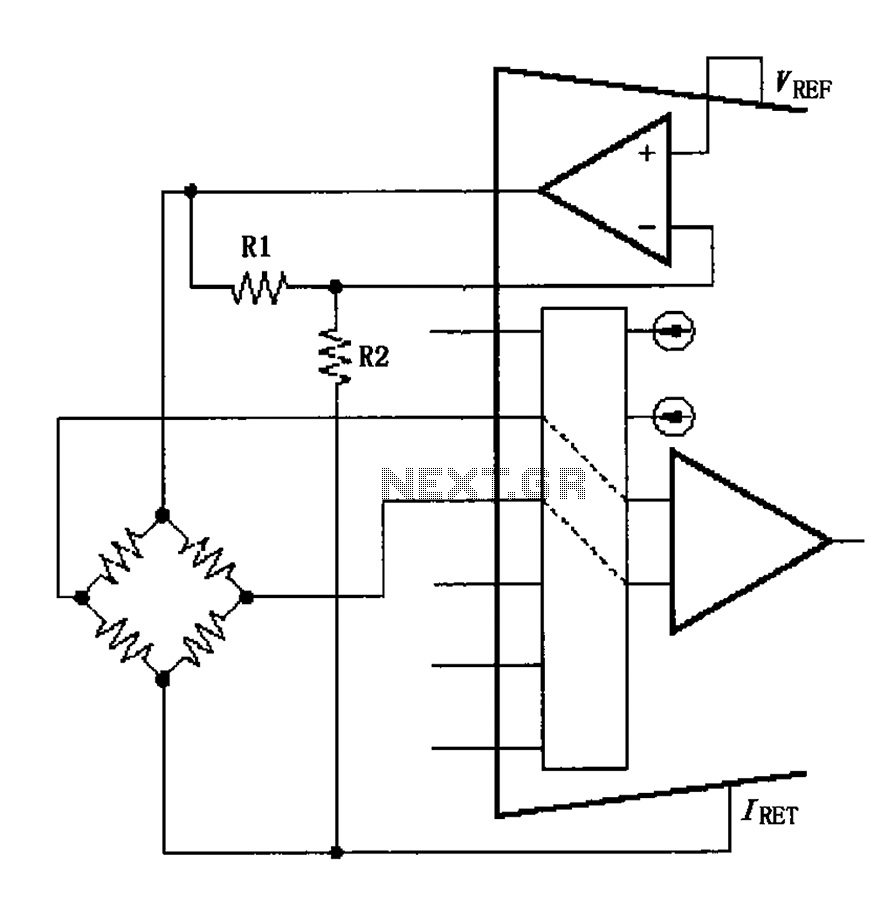

The electric thermos temperature detection control circuit operates by integrating several key components to ensure efficient temperature management. The control circuit for the boiler heater is responsible for regulating the heating element's operation based on the temperature readings from the thermistor or temperature sensor. This regulation ensures that the water or liquid within the thermos maintains the desired temperature without overheating or cooling excessively.

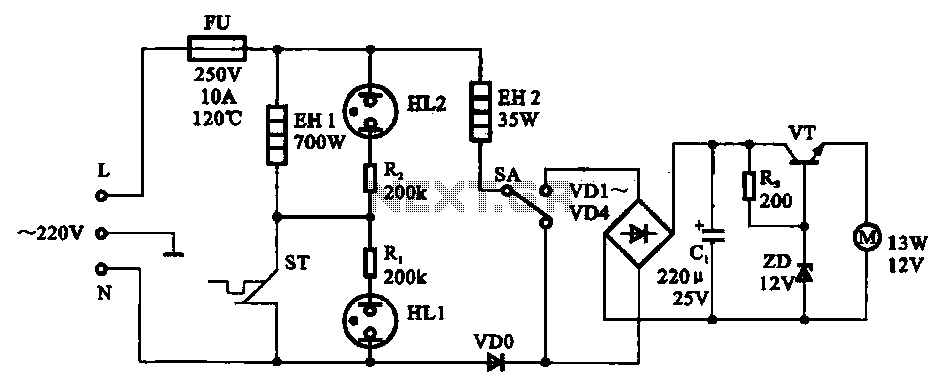

The heater insulation component plays a critical role in minimizing heat loss. It surrounds the heating element and the thermos body, providing thermal resistance that helps maintain the internal temperature. This insulation is crucial for energy efficiency and prolongs the heating duration.

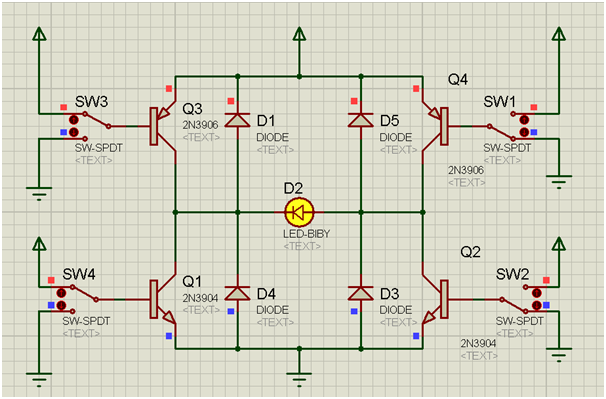

The electrical magnetic pump motor drive circuit facilitates the movement of liquid within the thermos. This circuit typically includes a relay or transistor that controls the operation of the pump motor. When activated, the pump circulates the liquid, ensuring uniform temperature distribution and preventing localized overheating.

Additionally, the heating and warming light circuit is designed to provide visual feedback regarding the operation of the heating system. This circuit may include LED indicators that illuminate when the heating element is active or when the thermos reaches the set temperature. Such indicators enhance user interaction by providing clear status updates.

Overall, the electric thermos temperature detection control circuit integrates these components into a cohesive system that efficiently manages temperature control, enhances user experience, and ensures optimal performance of the electric thermos.Electric thermos temperature detection control circuit Electric thermos shows the temperature detection control circuit. It is mainly by the control circuit of the boiler heate r and heater insulation, electrical magnetic pump motor drive circuit, as well as heating and warm light circuit configuration.

The electric thermos temperature detection control circuit operates by integrating several key components to ensure efficient temperature management. The control circuit for the boiler heater is responsible for regulating the heating element's operation based on the temperature readings from the thermistor or temperature sensor. This regulation ensures that the water or liquid within the thermos maintains the desired temperature without overheating or cooling excessively.

The heater insulation component plays a critical role in minimizing heat loss. It surrounds the heating element and the thermos body, providing thermal resistance that helps maintain the internal temperature. This insulation is crucial for energy efficiency and prolongs the heating duration.

The electrical magnetic pump motor drive circuit facilitates the movement of liquid within the thermos. This circuit typically includes a relay or transistor that controls the operation of the pump motor. When activated, the pump circulates the liquid, ensuring uniform temperature distribution and preventing localized overheating.

Additionally, the heating and warming light circuit is designed to provide visual feedback regarding the operation of the heating system. This circuit may include LED indicators that illuminate when the heating element is active or when the thermos reaches the set temperature. Such indicators enhance user interaction by providing clear status updates.

Overall, the electric thermos temperature detection control circuit integrates these components into a cohesive system that efficiently manages temperature control, enhances user experience, and ensures optimal performance of the electric thermos.Electric thermos temperature detection control circuit Electric thermos shows the temperature detection control circuit. It is mainly by the control circuit of the boiler heate r and heater insulation, electrical magnetic pump motor drive circuit, as well as heating and warm light circuit configuration.