Electronic Scale Circuit

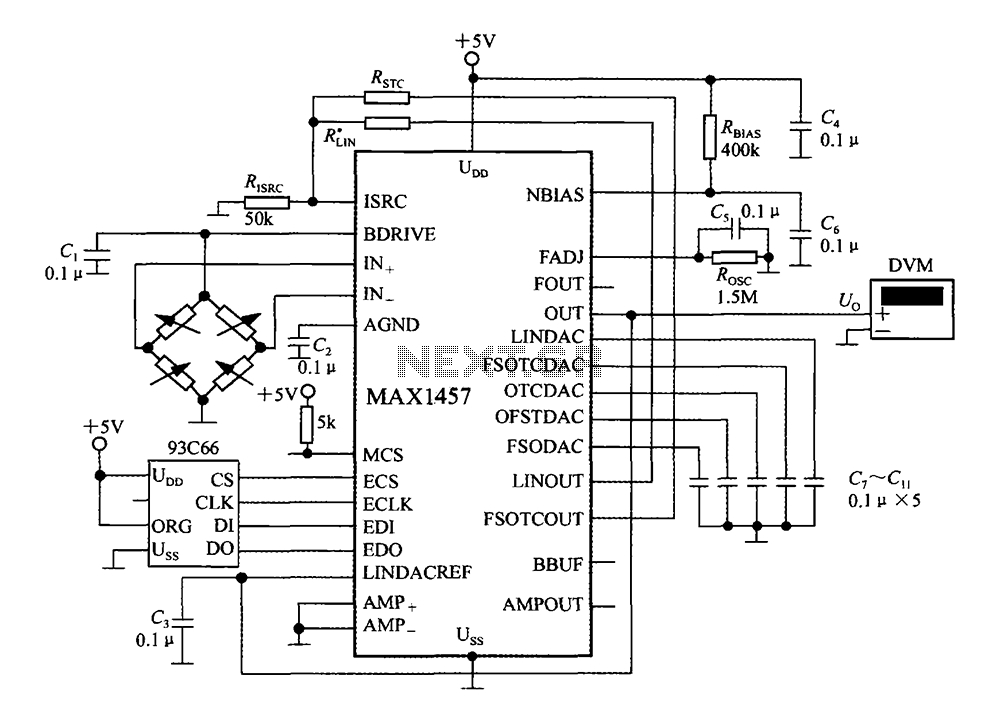

An electronic scale utilizes a pressure transducer (load cell) along with an analog-to-digital (A/D) converter to operate a digital display. The scale's range is determined by the specifications of the load cell, and the display is calibrated in suitable measurement units. The components are distributed across the main circuit board and the display board, while the external controls are located on the front panel and within the casing. The load cell in this scale is rated for a maximum capacity of 1 to 3 pounds (600 grams).

The electronic scale operates by converting the mechanical force exerted on the load cell into an electrical signal. The load cell, typically a strain gauge type, deforms under the weight applied to it, generating a change in resistance that is proportional to the load. This change is measured and converted into a digital signal by the A/D converter. The converter translates the analog voltage signal from the load cell into a digital format that can be processed by a microcontroller or microprocessor.

The microcontroller is programmed to interpret the digital signal and convert it into a readable value displayed on the digital screen. Calibration is essential to ensure accuracy; this involves adjusting the scale to display the correct weight corresponding to known weights. The display can be configured to show the weight in various units, such as pounds or kilograms, depending on user preference.

The main circuit board houses the load cell, A/D converter, and the microcontroller, while the display board contains the digital display elements, such as LED or LCD screens. The front panel includes user controls, such as buttons for zeroing the scale, switching between measurement units, and possibly a tare function to subtract the weight of containers. The design ensures that all components are securely mounted within the casing, providing durability and ease of use.

Overall, the electronic scale's design is focused on precision, reliability, and user-friendliness, making it suitable for various applications where weight measurement is required. An electronic scale using a pressure transducer (load cell) and an analog-digital (A/D) converter to drive a digital display is shown. The scale range depends on load cell. Display is calibrated in appropriate units. Components are on main circuit and display boards. The off-board controls are on the front panel and case. The cell in this scale is rated for 1.-3-pounds (600 grams).

The electronic scale operates by converting the mechanical force exerted on the load cell into an electrical signal. The load cell, typically a strain gauge type, deforms under the weight applied to it, generating a change in resistance that is proportional to the load. This change is measured and converted into a digital signal by the A/D converter. The converter translates the analog voltage signal from the load cell into a digital format that can be processed by a microcontroller or microprocessor.

The microcontroller is programmed to interpret the digital signal and convert it into a readable value displayed on the digital screen. Calibration is essential to ensure accuracy; this involves adjusting the scale to display the correct weight corresponding to known weights. The display can be configured to show the weight in various units, such as pounds or kilograms, depending on user preference.

The main circuit board houses the load cell, A/D converter, and the microcontroller, while the display board contains the digital display elements, such as LED or LCD screens. The front panel includes user controls, such as buttons for zeroing the scale, switching between measurement units, and possibly a tare function to subtract the weight of containers. The design ensures that all components are securely mounted within the casing, providing durability and ease of use.

Overall, the electronic scale's design is focused on precision, reliability, and user-friendliness, making it suitable for various applications where weight measurement is required. An electronic scale using a pressure transducer (load cell) and an analog-digital (A/D) converter to drive a digital display is shown. The scale range depends on load cell. Display is calibrated in appropriate units. Components are on main circuit and display boards. The off-board controls are on the front panel and case. The cell in this scale is rated for 1.-3-pounds (600 grams).