FGDF-3 three-phase low-temperature iron plating power commutation control switch and electronic circuit

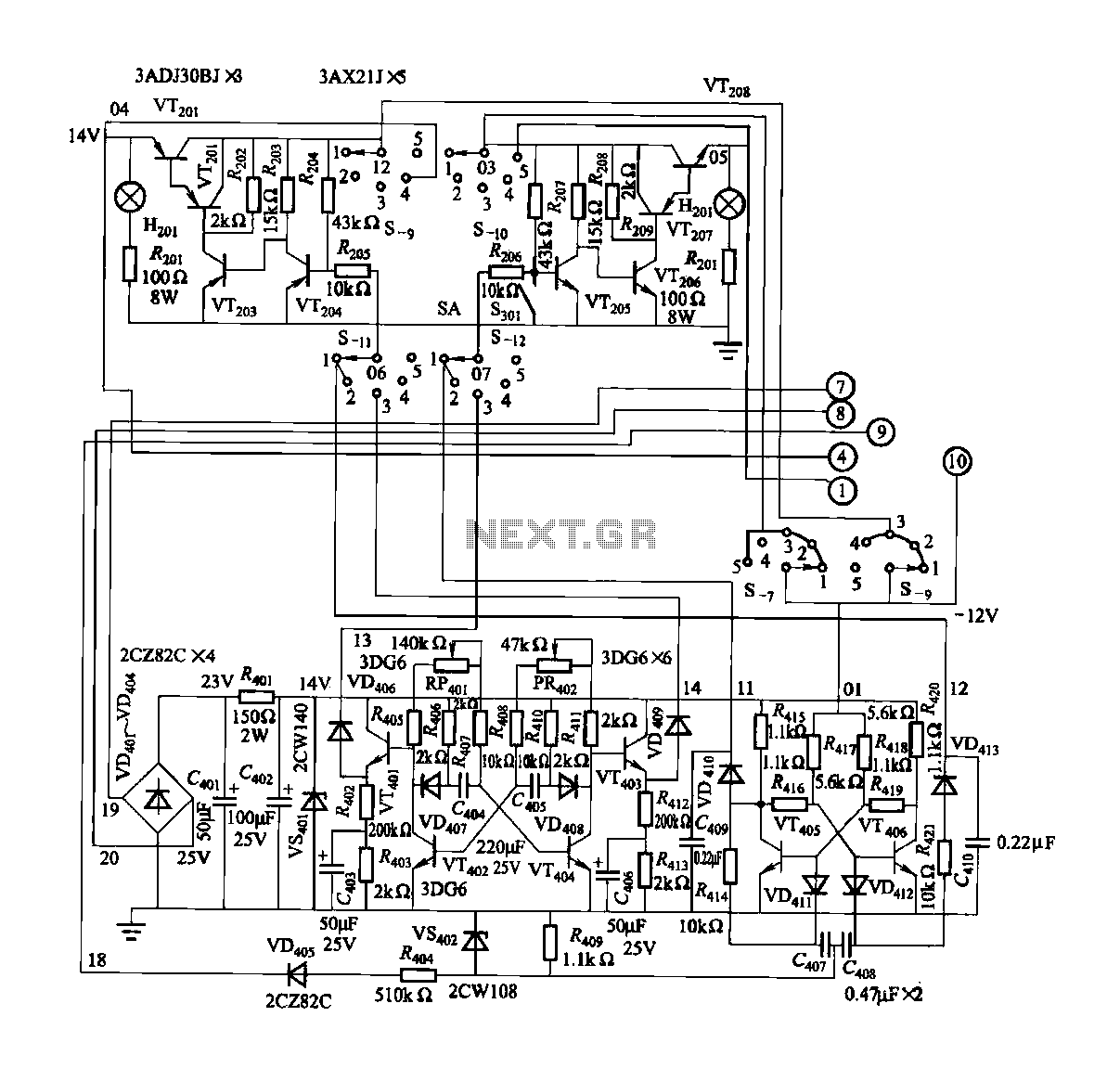

FGDF-3 is a three-phase low-temperature iron plating power commutation control switch and electronic circuit. The KGDF-3 serves as a low-temperature iron plating power supply device, incorporating the characteristics of a single-phase low-temperature iron plating power supply. This design facilitates an even load distribution across a three-phase power grid. The technical parameters of the power supply unit are as follows: AC input voltage is three-phase 380V at 50Hz; DC output voltage includes a positive DC of -16V (continuously adjustable) and a reverse DC ranging from 0 to 16V (adjustable). The rated output current features an AC symmetry output disability of 50A, a chi flow asymmetry output from 0 to 500A, and a reversed polarity DC output from 0 to +100A. The positive DC output ranges from 0 to +100A, while the reverse DC output can reach -1000A. The forward time control is adjustable from 1 to 30 seconds (with a specific range of 1 to 22 seconds), and the reverse time control can be set between 0.5 to 2 seconds (with a specific range of 0.5 to 1 second). Adjustable brackets are provided for actual number settings.

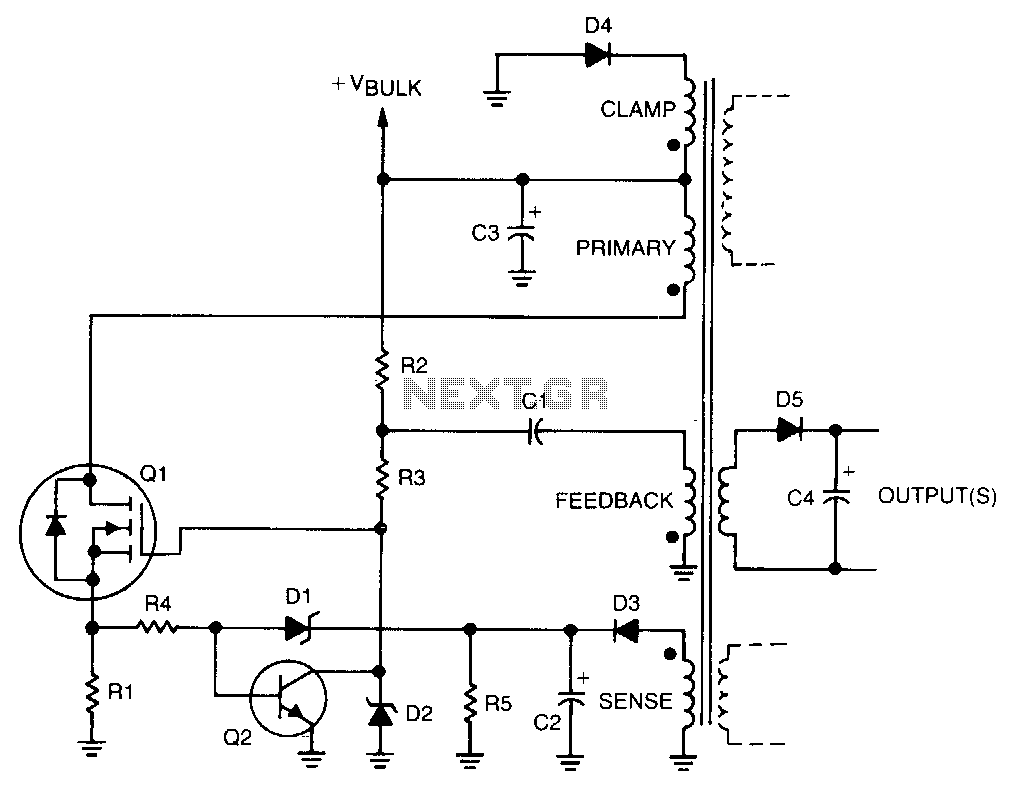

The FGDF-3 circuit operates on a three-phase input, which allows for balanced loading and improved efficiency in power distribution. The design incorporates a control switch that manages the transition between different operational states, facilitating both forward and reverse plating processes. The adjustable DC output voltages enable precise control over the plating process, allowing for fine-tuning based on the specific requirements of the application.

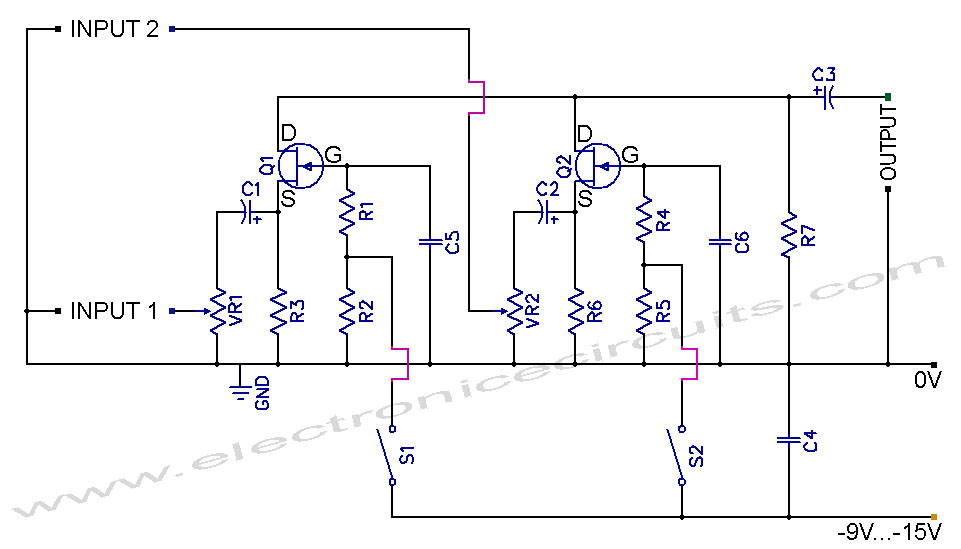

The AC input is transformed and rectified to provide the necessary DC output, which is essential for the electroplating process. The use of adjustable parameters such as the output voltage and current ensures flexibility in operation, accommodating various plating thicknesses and materials.

The forward and reverse time controls are critical for managing the duration of the plating process. This feature allows operators to optimize the plating cycle, improving the quality of the deposited layer while minimizing waste. The symmetrical and asymmetrical current outputs are designed to handle different plating scenarios, making the unit versatile for various industrial applications.

Safety features may also be integrated into the design to protect against overcurrent and overheating, ensuring reliable operation under demanding conditions. Overall, the FGDF-3 circuit represents an advanced solution for low-temperature iron plating, combining efficiency, flexibility, and control in a compact design.FGDF-3 three-phase low-temperature iron plating power commutation control switch and electronic circuit KGDF-3 low-temperature iron plating power supply device having a single- phase low-temperature iron plating all the characteristics of the power supply device. In addition, the use of three-phase power grid load evenly. Technical parameters of the power supply unit: AC input voltage, three-phase 380V, 50Hz: DC output voltage, positive DC -16V (continuously adjustable), reverse DC 0 ~ 16V (adjustable); rated output current, AC symmetry output disabilities 50A, Chi flow asymmetry output 0 ~ 500A, reversed polarity DC output O ~ + lOOOA, positive DC O- + lOOOA, reverse DC ~ -1000A, forward time control 1 ~ 30s (1 ~ 22s) reverse time control 0.5-2s (0. 5-ls). Adjustable brackets above the actual number.

The FGDF-3 circuit operates on a three-phase input, which allows for balanced loading and improved efficiency in power distribution. The design incorporates a control switch that manages the transition between different operational states, facilitating both forward and reverse plating processes. The adjustable DC output voltages enable precise control over the plating process, allowing for fine-tuning based on the specific requirements of the application.

The AC input is transformed and rectified to provide the necessary DC output, which is essential for the electroplating process. The use of adjustable parameters such as the output voltage and current ensures flexibility in operation, accommodating various plating thicknesses and materials.

The forward and reverse time controls are critical for managing the duration of the plating process. This feature allows operators to optimize the plating cycle, improving the quality of the deposited layer while minimizing waste. The symmetrical and asymmetrical current outputs are designed to handle different plating scenarios, making the unit versatile for various industrial applications.

Safety features may also be integrated into the design to protect against overcurrent and overheating, ensuring reliable operation under demanding conditions. Overall, the FGDF-3 circuit represents an advanced solution for low-temperature iron plating, combining efficiency, flexibility, and control in a compact design.FGDF-3 three-phase low-temperature iron plating power commutation control switch and electronic circuit KGDF-3 low-temperature iron plating power supply device having a single- phase low-temperature iron plating all the characteristics of the power supply device. In addition, the use of three-phase power grid load evenly. Technical parameters of the power supply unit: AC input voltage, three-phase 380V, 50Hz: DC output voltage, positive DC -16V (continuously adjustable), reverse DC 0 ~ 16V (adjustable); rated output current, AC symmetry output disabilities 50A, Chi flow asymmetry output 0 ~ 500A, reversed polarity DC output O ~ + lOOOA, positive DC O- + lOOOA, reverse DC ~ -1000A, forward time control 1 ~ 30s (1 ~ 22s) reverse time control 0.5-2s (0. 5-ls). Adjustable brackets above the actual number.