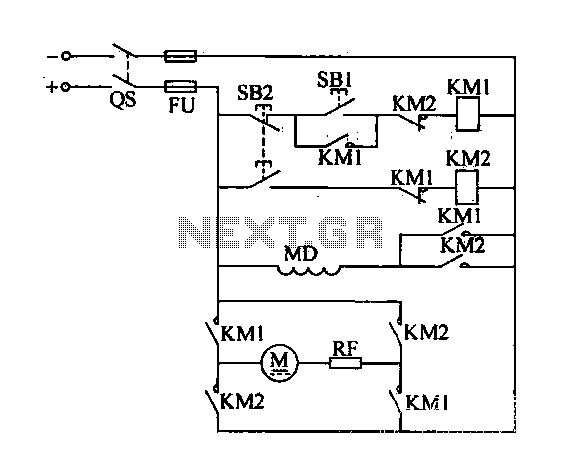

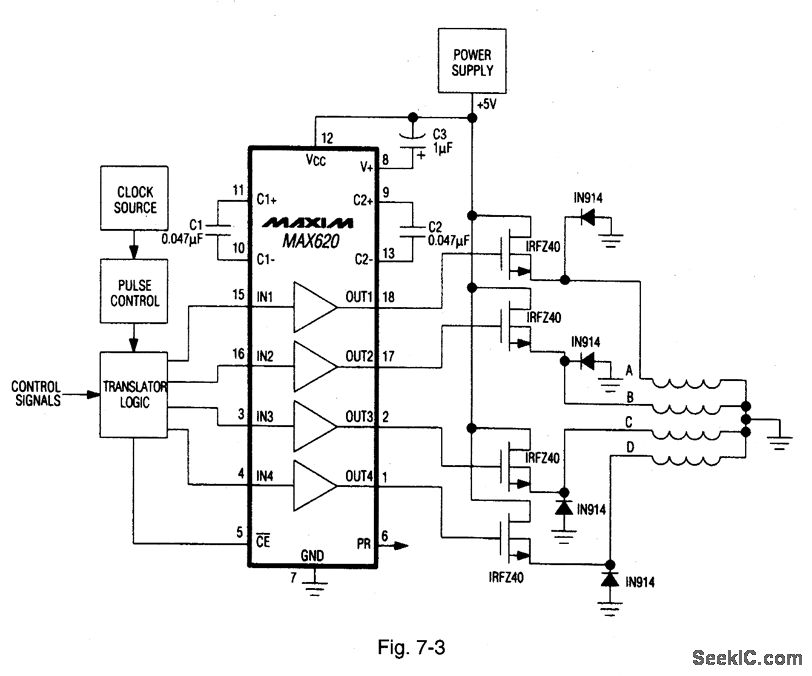

Four phase stepper motor drive system

A MAX620 is connected to create a complete stepper motor drive system. TTL/CMOS signals from the logic network are converted to high-side levels that control four N-channel power MOSFETs, which supply current to each of the four phases of the stepper motor. Diodes are included to provide a discharge current path for the stepper motor windings.

The MAX620 is a high-performance, integrated circuit that functions as a high-side driver, suitable for controlling power MOSFETs in various applications, including stepper motor drives. In this configuration, the device effectively translates low-voltage TTL or CMOS logic signals into higher voltage levels necessary for driving the gate of N-channel MOSFETs. This translation is essential for ensuring that the MOSFETs can fully turn on, allowing efficient current flow to the stepper motor phases.

The four N-channel MOSFETs are arranged in a H-bridge configuration, enabling bidirectional control of the motor phases. This arrangement allows for precise control of the motor's rotation direction and speed by alternating the current flow through the motor windings. Each MOSFET is activated by the output from the MAX620, which is driven by the logic network. This network typically includes a microcontroller or other digital logic devices that generate the control signals based on the desired motor operation.

The inclusion of diodes in the circuit is crucial for protecting the MOSFETs and ensuring reliable operation. When the current through the motor windings is interrupted, the inductive nature of the windings can generate back EMF, which may damage the MOSFETs if not properly managed. The diodes provide a safe path for this discharge current, preventing voltage spikes that could lead to component failure.

Overall, this stepper motor drive configuration utilizing the MAX620 and N-channel MOSFETs offers a robust solution for controlling stepper motors in various applications, providing high efficiency and reliability in operation.A MAX620 connected to form a complete stepper-motor drive. TTL/CMOS signals from the logic network are translated to high-side levels that drive four N-channel power MOSFETs, supplying current to each of four stepper-motor phases. The diodes provide a discharge current path for the stepper-motor windings. MAXIM NEW RELEASES DATA B OOk, 1992, P. 4-28. 🔗 External reference

The MAX620 is a high-performance, integrated circuit that functions as a high-side driver, suitable for controlling power MOSFETs in various applications, including stepper motor drives. In this configuration, the device effectively translates low-voltage TTL or CMOS logic signals into higher voltage levels necessary for driving the gate of N-channel MOSFETs. This translation is essential for ensuring that the MOSFETs can fully turn on, allowing efficient current flow to the stepper motor phases.

The four N-channel MOSFETs are arranged in a H-bridge configuration, enabling bidirectional control of the motor phases. This arrangement allows for precise control of the motor's rotation direction and speed by alternating the current flow through the motor windings. Each MOSFET is activated by the output from the MAX620, which is driven by the logic network. This network typically includes a microcontroller or other digital logic devices that generate the control signals based on the desired motor operation.

The inclusion of diodes in the circuit is crucial for protecting the MOSFETs and ensuring reliable operation. When the current through the motor windings is interrupted, the inductive nature of the windings can generate back EMF, which may damage the MOSFETs if not properly managed. The diodes provide a safe path for this discharge current, preventing voltage spikes that could lead to component failure.

Overall, this stepper motor drive configuration utilizing the MAX620 and N-channel MOSFETs offers a robust solution for controlling stepper motors in various applications, providing high efficiency and reliability in operation.A MAX620 connected to form a complete stepper-motor drive. TTL/CMOS signals from the logic network are translated to high-side levels that drive four N-channel power MOSFETs, supplying current to each of four stepper-motor phases. The diodes provide a discharge current path for the stepper-motor windings. MAXIM NEW RELEASES DATA B OOk, 1992, P. 4-28. 🔗 External reference