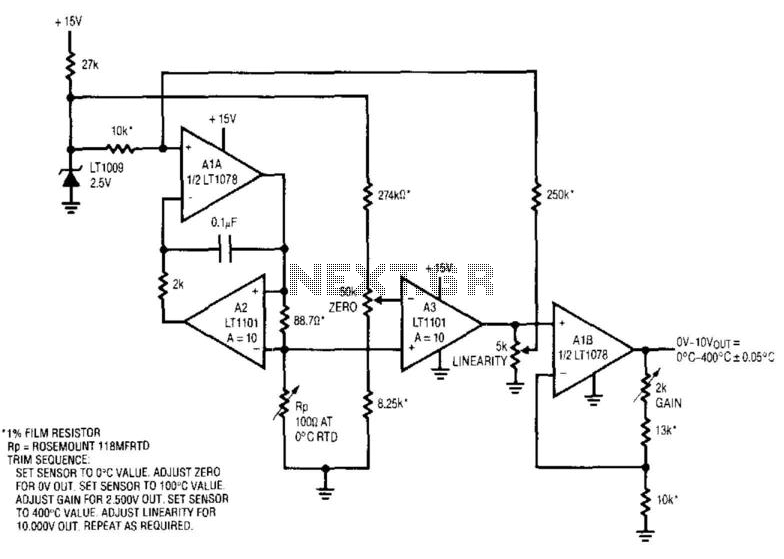

High-Accuracy Thermometer

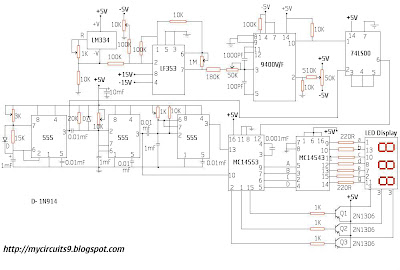

This circuit integrates a current source and a platinum RTD bridge to create a high-accuracy thermometer. The ground-referred RTD is part of a bridge that includes the current drive and the LT1009 biased resistor string. The current drive enables the voltage across the RTD to change in direct relation to its temperature-induced resistance variation. The output of the bridge is determined by the difference between this voltage and that of the opposing leg of the bridge. The constant drive through the RTD ensures that the voltage across it changes with its resistance, which exhibits a nearly linear positive temperature coefficient. However, this nonlinearity could introduce several degrees of error across the circuit's operating range of 0°C to 400°C. The output from the bridge is sent to instrumentation amplifier A3, which provides differential gain and nonlinearity correction. This correction is achieved by feeding a portion of A3's output back to A1's input through a 10 to 250 kΩ divider. This feedback adjusts the current supplied to RP, slightly modifying its operating point to compensate for sensor nonlinearity within ±0.05°C. A1B, which provides additional scaled gain, produces the final circuit output. Calibration of this circuit should follow the procedure outlined in the accompanying diagram.

The circuit design employs a platinum Resistance Temperature Detector (RTD) configured in a Wheatstone bridge arrangement, which is essential for precise temperature measurement. The current source drives the RTD, allowing for a consistent current flow that generates a voltage proportional to the resistance change of the RTD due to temperature variations. The LT1009 operational amplifier is utilized for its high precision and stability, ensuring minimal drift and noise in the measurements.

The bridge output is sensitive to temperature changes, and the differential amplifier configuration of A3 enhances the signal while simultaneously correcting for any nonlinearity introduced by the RTD. The feedback mechanism through the resistive divider allows for fine-tuning of the output, ensuring that the temperature readings remain accurate across the specified range. This feedback loop is vital for maintaining the integrity of the measurement, especially in applications where precision is critical.

In terms of calibration, it is essential to follow a systematic approach as outlined in the accompanying diagram to ensure that the thermometer operates within its specified accuracy limits. Calibration typically involves comparing the thermometer readings against a known temperature standard and adjusting the feedback network to account for any discrepancies.

Overall, this circuit exemplifies a sophisticated approach to temperature measurement, integrating advanced components and techniques to achieve high accuracy and reliability in various applications, including industrial and laboratory environments. This circuit combines a current source and a platinum RTD bridge to form a complete high-accuracy thermometer. Th e ground-referred RTD sits in a bridge that is composed of the current drive and the LT1009 biased resistor string. The current drive allows the voltage across the RTD to vary directly with its temperature-induced resistance shift.

The difference between this potential and that of the opposing bridge leg forms the bridge output. The RTD"s constant drive forces the voltage across it to vary with its resistance, which has a nearly linear positive temperature coefficient. The nonlinearity could cause several degrees of error over the circuit"s 0°C -400°C operating range.

The bridge"s output is fed to instrumentation amplifier A3, which provides differential gain, while simultaneously supplying nonlinearity correction. The correction is implemented by feeding a portion of A3"s output back to Al"s input via the 10- to 250-KOhmhm divider.

This causes the current supplied to RP to slightly shift with its operating point, compensating sensor nonlinearity to within ±0.05°C. A1B, providing additional scaled gain, furnishes the circuit output. To calibrate this circuit, follow the procedure given in the diagram.

The circuit design employs a platinum Resistance Temperature Detector (RTD) configured in a Wheatstone bridge arrangement, which is essential for precise temperature measurement. The current source drives the RTD, allowing for a consistent current flow that generates a voltage proportional to the resistance change of the RTD due to temperature variations. The LT1009 operational amplifier is utilized for its high precision and stability, ensuring minimal drift and noise in the measurements.

The bridge output is sensitive to temperature changes, and the differential amplifier configuration of A3 enhances the signal while simultaneously correcting for any nonlinearity introduced by the RTD. The feedback mechanism through the resistive divider allows for fine-tuning of the output, ensuring that the temperature readings remain accurate across the specified range. This feedback loop is vital for maintaining the integrity of the measurement, especially in applications where precision is critical.

In terms of calibration, it is essential to follow a systematic approach as outlined in the accompanying diagram to ensure that the thermometer operates within its specified accuracy limits. Calibration typically involves comparing the thermometer readings against a known temperature standard and adjusting the feedback network to account for any discrepancies.

Overall, this circuit exemplifies a sophisticated approach to temperature measurement, integrating advanced components and techniques to achieve high accuracy and reliability in various applications, including industrial and laboratory environments. This circuit combines a current source and a platinum RTD bridge to form a complete high-accuracy thermometer. Th e ground-referred RTD sits in a bridge that is composed of the current drive and the LT1009 biased resistor string. The current drive allows the voltage across the RTD to vary directly with its temperature-induced resistance shift.

The difference between this potential and that of the opposing bridge leg forms the bridge output. The RTD"s constant drive forces the voltage across it to vary with its resistance, which has a nearly linear positive temperature coefficient. The nonlinearity could cause several degrees of error over the circuit"s 0°C -400°C operating range.

The bridge"s output is fed to instrumentation amplifier A3, which provides differential gain, while simultaneously supplying nonlinearity correction. The correction is implemented by feeding a portion of A3"s output back to Al"s input via the 10- to 250-KOhmhm divider.

This causes the current supplied to RP to slightly shift with its operating point, compensating sensor nonlinearity to within ±0.05°C. A1B, providing additional scaled gain, furnishes the circuit output. To calibrate this circuit, follow the procedure given in the diagram.