High voltage ohmmeters

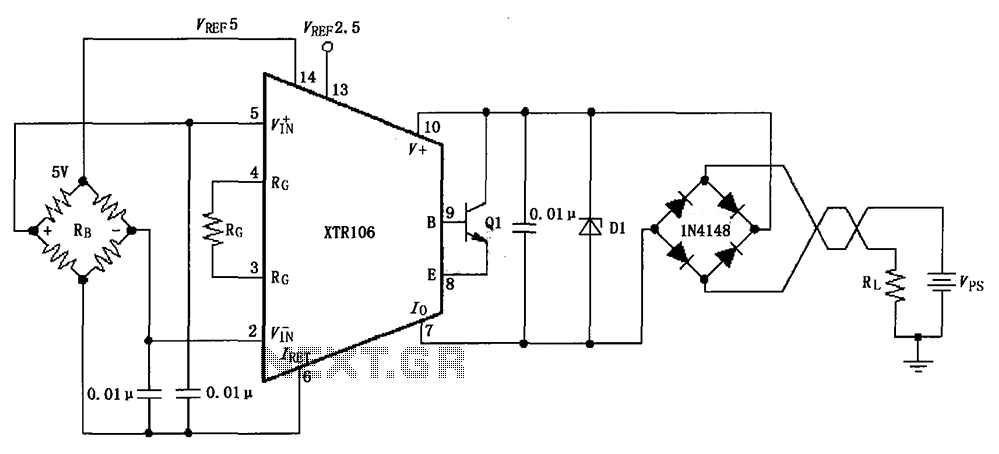

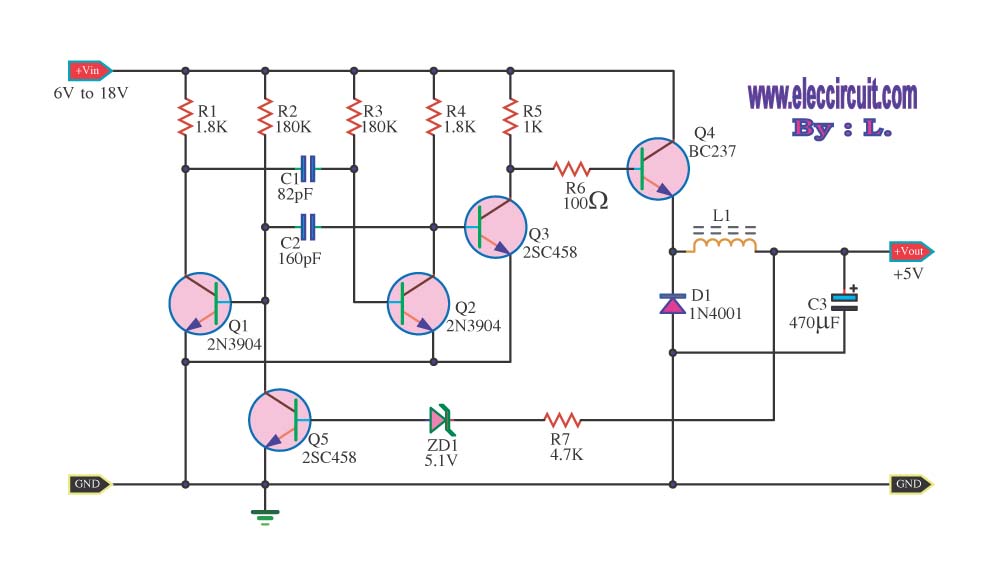

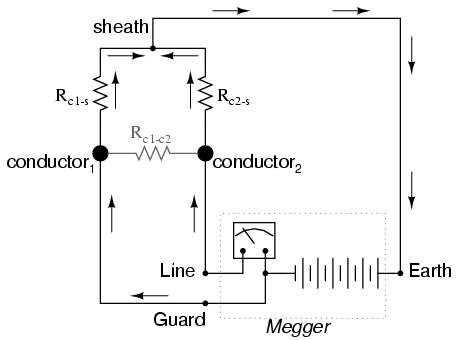

Most ohmmeters of the design shown in the previous section utilize a battery of relatively low voltage, usually nine volts or less. This is adequate for measuring resistances under several mega-ohms (MΩ), but when extremely high resistances need to be measured, a 9-volt battery is insufficient for generating enough current to actuate an electromechanical meter movement. Resistance is not always a stable (linear) quantity, particularly for non-metals. For instance, the graph of current over voltage for a small air gap (less than an inch) illustrates nonlinear conduction. Other materials exhibit similar insulating/conducting properties under high voltages. An ohmmeter powered by a low-voltage battery cannot measure resistance at the ionization potential of a gas or the breakdown voltage of an insulator. For such measurements, a high-voltage ohmmeter is necessary. The most straightforward method for high-voltage resistance measurement involves substituting a higher voltage battery into the basic design of the previously discussed ohmmeter. However, as the resistance of some materials varies with applied voltage, it would be beneficial to adjust the voltage of this ohmmeter for different resistance measurements. This introduces a calibration issue; if the meter movement deflects full-scale with a certain current, the full-scale range in ohms will vary with the source voltage. For example, connecting a stable resistance across the test leads while varying the source voltage will result in increased current through the meter movement as voltage rises, leading to greater deflection. A meter movement capable of producing consistent, stable deflection for any stable resistance value, regardless of the applied voltage, is required. The numbered, rectangular blocks in the illustration represent cross-sectional wire coils, which all move with the needle mechanism. There is no spring mechanism to return the needle to a set position, causing it to "float" when unpowered. In an open circuit (infinite resistance between the test leads), there is no current through coil 1, only through coils 2 and 3. When energized, these coils attempt to center themselves in the magnetic gap, driving the needle to the far right of the scale, indicating "infinity." Any current through coil 1 (from a measured resistance connected between the test leads) drives the needle leftward, back to zero. The internal resistor values of the meter movement are calibrated so that when the test leads are shorted, the needle deflects exactly to the 0Ω position. Variations in battery voltage affect the torque generated by both sets of coils (coils 2 and 3 driving the needle right and coil 1 driving it left), but do not affect the calibration of the movement. Thus, the accuracy of this ohmmeter movement remains unaffected by battery voltage; a specific measured resistance will produce a consistent needle deflection, regardless of the battery voltage. The only influence of voltage variation on meter indication is the extent to which the measured resistance changes with applied voltage. For instance, using a megger to measure the resistance of a gas-discharge lamp would yield a very high resistance reading (needle at the far right of the scale) at low voltages and a low resistance reading (needle moving left) at higher voltages.

The high-voltage ohmmeter operates on the principle of varying the applied voltage to assess resistance in non-linear materials effectively. The design incorporates a robust electromechanical meter movement that utilizes multiple coils to achieve stable readings. Each coil is strategically placed within a magnetic field, allowing for precise needle deflection based on the current flowing through the test leads. This configuration ensures that the device can accurately measure a wide range of resistances while accounting for the inherent variability in resistance due to changes in voltage.

The calibration of the meter is critical to maintain accuracy, especially when measuring high resistances. The design avoids the pitfalls of traditional ohmmeters that rely on a single voltage level, which can lead to misleading readings when dealing with materials that exhibit non-linear resistance characteristics. By allowing for voltage adjustments, the high-voltage ohmmeter can be tailored to the specific requirements of the measurement task at hand.

In practical applications, such a device is invaluable in fields where high-voltage insulation testing is necessary, such as in the evaluation of electrical components, insulation systems, and safety testing of electrical equipment. The ability to produce reliable resistance measurements across a range of conditions enhances the utility of this high-voltage ohmmeter, making it a crucial tool for engineers and technicians in the electrical and electronics industries.Most ohmmeters of the design shown in the previous section utilize a battery of relatively low voltage, usually nine volts or less. This is perfectly adequate for measuring resistances under several mega-ohms (M ©), but when extremely high resistances need to be measured, a 9 volt battery is insufficient for generating enough current to actuate an electromechanical

meter movement. Also, as discussed in an earlier chapter, resistance is not always a stable (linear) quantity. This is especially true of non-metals. Recall the graph of current over voltage for a small air gap (less than an inch): While this is an extreme example of nonlinear conduction, other substances exhibit similar insulating/conducting properties when exposed to high voltages. Obviously, an ohmmeter using a low-voltage battery as a source of power cannot measure resistance at the ionization potential of a gas, or at the breakdown voltage of an insulator.

If such resistance values need to be measured, nothing but a high-voltage ohmmeter will suffice. The most direct method of high-voltage resistance measurement involves simply substituting a higher voltage battery in the same basic design of ohmmeter investigated earlier: Knowing, however, that the resistance of some materials tends to change with applied voltage, it would be advantageous to be able to adjust the voltage of this ohmmeter to obtain resistance measurements under different conditions: Unfortunately, this would create a calibration problem for the meter. If the meter movement deflects full-scale with a certain amount of current through it, the full-scale range of the meter in ohms would change as the source voltage changed.

Imagine connecting a stable resistance across the test leads of this ohmmeter while varying the source voltage: as the voltage is increased, there will be more current through the meter movement, hence a greater amount of deflection. What we really need is a meter movement that will produce a consistent, stable deflection for any stable resistance value measured, regardless of the applied voltage.

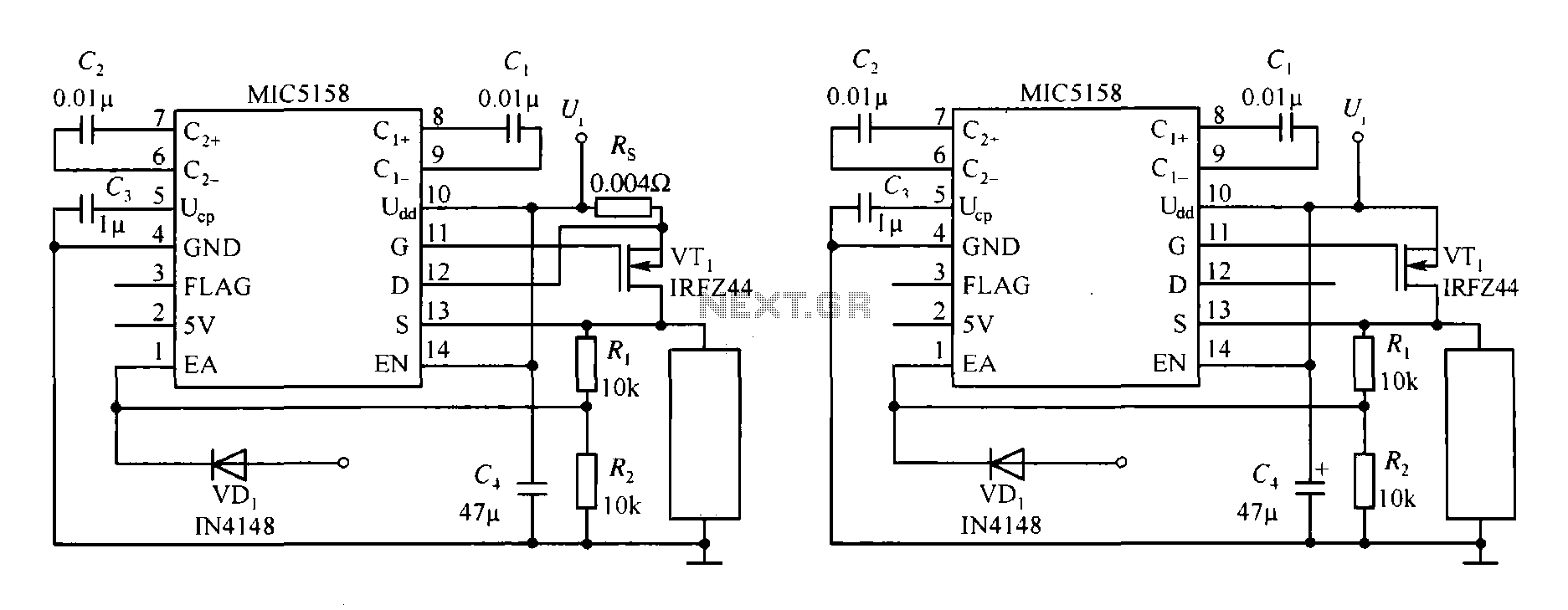

The numbered, rectangular blocks in the above illustration are cross-sectional representations of wire coils. These three coils all move with the needle mechanism. There is no spring mechanism to return the needle to a set position. When the movement is unpowered, the needle will randomly "float. " The coils are electrically connected like this: With infinite resistance between the test leads (open circuit), there will be no current through coil 1, only through coils 2 and 3.

When energized, these coils try to center themselves in the gap between the two magnet poles, driving the needle fully to the right of the scale where it points to "infinity. " Any current through coil 1 (through a measured resistance connected between the test leads) tends to drive the needle to the left of scale, back to zero.

The internal resistor values of the meter movement are calibrated so that when the test leads are shorted together, the needle deflects exactly to the 0 © position. Because any variations in battery voltage will affect the torque generated by both sets of coils (coils 2 and 3, which drive the needle to the right, and coil 1, which drives the needle to the left), those variations will have no effect of the calibration of the movement.

In other words, the accuracy of this ohmmeter movement is unaffected by battery voltage: a given amount of measured resistance will produce a certain needle deflection, no matter how much or little battery voltage is present. The only effect that a variation in voltage will have on meter indication is the degree to which the measured resistance changes with applied voltage.

So, if we were to use a megger to measure the resistance of a gas-discharge lamp, it would read very high resistance (needle to the far right of the scale) for low voltages and low resistance (needle moves to the left of the s 🔗 External reference

The high-voltage ohmmeter operates on the principle of varying the applied voltage to assess resistance in non-linear materials effectively. The design incorporates a robust electromechanical meter movement that utilizes multiple coils to achieve stable readings. Each coil is strategically placed within a magnetic field, allowing for precise needle deflection based on the current flowing through the test leads. This configuration ensures that the device can accurately measure a wide range of resistances while accounting for the inherent variability in resistance due to changes in voltage.

The calibration of the meter is critical to maintain accuracy, especially when measuring high resistances. The design avoids the pitfalls of traditional ohmmeters that rely on a single voltage level, which can lead to misleading readings when dealing with materials that exhibit non-linear resistance characteristics. By allowing for voltage adjustments, the high-voltage ohmmeter can be tailored to the specific requirements of the measurement task at hand.

In practical applications, such a device is invaluable in fields where high-voltage insulation testing is necessary, such as in the evaluation of electrical components, insulation systems, and safety testing of electrical equipment. The ability to produce reliable resistance measurements across a range of conditions enhances the utility of this high-voltage ohmmeter, making it a crucial tool for engineers and technicians in the electrical and electronics industries.Most ohmmeters of the design shown in the previous section utilize a battery of relatively low voltage, usually nine volts or less. This is perfectly adequate for measuring resistances under several mega-ohms (M ©), but when extremely high resistances need to be measured, a 9 volt battery is insufficient for generating enough current to actuate an electromechanical

meter movement. Also, as discussed in an earlier chapter, resistance is not always a stable (linear) quantity. This is especially true of non-metals. Recall the graph of current over voltage for a small air gap (less than an inch): While this is an extreme example of nonlinear conduction, other substances exhibit similar insulating/conducting properties when exposed to high voltages. Obviously, an ohmmeter using a low-voltage battery as a source of power cannot measure resistance at the ionization potential of a gas, or at the breakdown voltage of an insulator.

If such resistance values need to be measured, nothing but a high-voltage ohmmeter will suffice. The most direct method of high-voltage resistance measurement involves simply substituting a higher voltage battery in the same basic design of ohmmeter investigated earlier: Knowing, however, that the resistance of some materials tends to change with applied voltage, it would be advantageous to be able to adjust the voltage of this ohmmeter to obtain resistance measurements under different conditions: Unfortunately, this would create a calibration problem for the meter. If the meter movement deflects full-scale with a certain amount of current through it, the full-scale range of the meter in ohms would change as the source voltage changed.

Imagine connecting a stable resistance across the test leads of this ohmmeter while varying the source voltage: as the voltage is increased, there will be more current through the meter movement, hence a greater amount of deflection. What we really need is a meter movement that will produce a consistent, stable deflection for any stable resistance value measured, regardless of the applied voltage.

The numbered, rectangular blocks in the above illustration are cross-sectional representations of wire coils. These three coils all move with the needle mechanism. There is no spring mechanism to return the needle to a set position. When the movement is unpowered, the needle will randomly "float. " The coils are electrically connected like this: With infinite resistance between the test leads (open circuit), there will be no current through coil 1, only through coils 2 and 3.

When energized, these coils try to center themselves in the gap between the two magnet poles, driving the needle fully to the right of the scale where it points to "infinity. " Any current through coil 1 (through a measured resistance connected between the test leads) tends to drive the needle to the left of scale, back to zero.

The internal resistor values of the meter movement are calibrated so that when the test leads are shorted together, the needle deflects exactly to the 0 © position. Because any variations in battery voltage will affect the torque generated by both sets of coils (coils 2 and 3, which drive the needle to the right, and coil 1, which drives the needle to the left), those variations will have no effect of the calibration of the movement.

In other words, the accuracy of this ohmmeter movement is unaffected by battery voltage: a given amount of measured resistance will produce a certain needle deflection, no matter how much or little battery voltage is present. The only effect that a variation in voltage will have on meter indication is the degree to which the measured resistance changes with applied voltage.

So, if we were to use a megger to measure the resistance of a gas-discharge lamp, it would read very high resistance (needle to the far right of the scale) for low voltages and low resistance (needle moves to the left of the s 🔗 External reference