improved vibrating battery

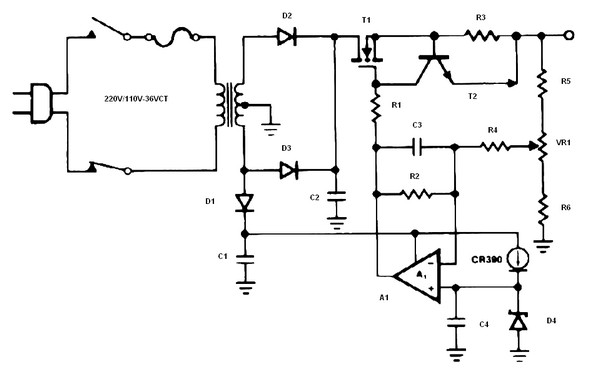

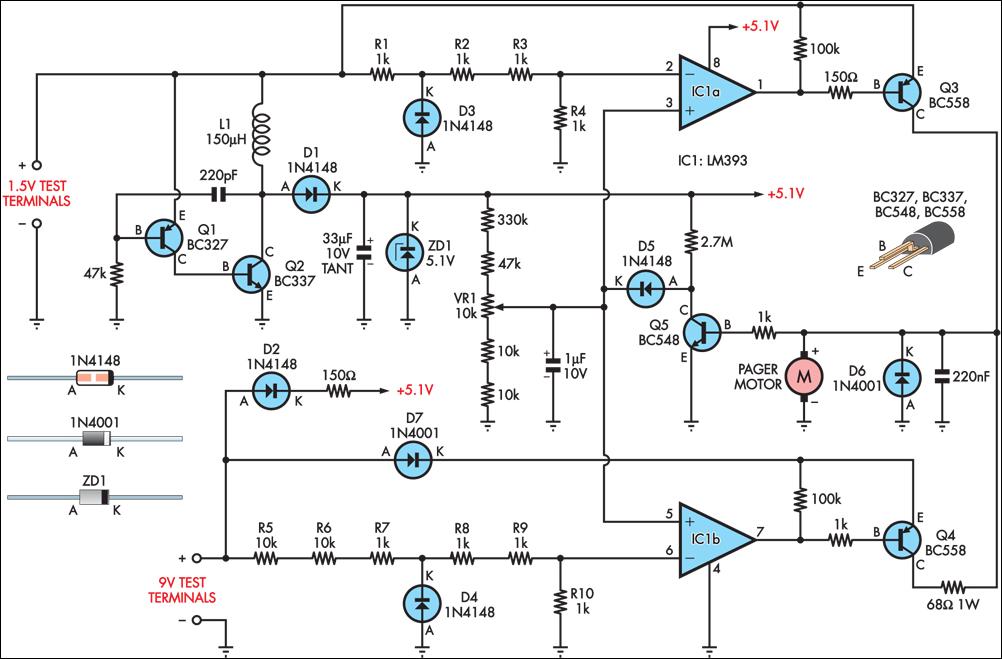

Many blind and deaf-blind individuals utilize portable electronic devices to assist in their daily activities; however, testing the batteries used in such equipment can be challenging. While talking voltmeters are available for the blind, there is no commercially available equivalent for deaf-blind individuals. This device allows blind, deaf-blind, and sighted people to test batteries. It is capable of testing AAA, AA, C, and D cells, as well as 9V "transistor" batteries, supporting all rechargeable and non-rechargeable cell types. The circuit requires no calibration. To operate the tester, the user turns the potentiometer VR1 fully counter-clockwise and connects the battery to the appropriate test terminals. If the battery has any usable charge, the pager motor in the tester will vibrate immediately. The user then rotates VR1 clockwise until the vibration stops. The position of VR1 indicates the loaded voltage of the battery on a scale of 1-1.5V (for 1.5V test terminals) or 6-9V (for 9V test terminals). A regulated +5.1V rail is generated from the battery under test using a zener diode (ZD1). For 9V tests, a 150Ω resistor limits the zener current, while diode D2 protects the circuit from reverse polarity battery connections. For 1.5V tests, a blocking oscillator formed by Q1, Q2, and L1 steps up the battery voltage before it is applied to the regulator, functioning reliably with inputs down to below 0.9V. The output of the oscillator is rectified by D1 and smoothed by a 33 µF capacitor. The circuit is designed to withstand reverse connections of the battery under test. This presents a challenge, as the LM393 cannot tolerate voltages more negative than -0.3V at its inputs. Diodes D1 and D2 provide indirect protection for the non-inverting inputs from negative voltages, but series diodes cannot be used to protect the inverting inputs due to the unpredictable voltage drop they introduce. The solution involves shunting negative voltages at the 1.5V test terminals with diode D3 in conjunction with a 1kΩ resistor (R1). D3 limits the voltage at its cathode to about -0.7V, while resistors R2-R4 divide this by three, resulting in no less than -0.23V at the inverting input (pin 2) of IC1a. When the battery is correctly connected, D3 is reverse-biased, and R1-R4 form a voltage divider that applies a quarter of the battery voltage to the inverting input of IC1a. Similarly, D4 and resistors R5-R10 protect the inverting input (pin 6) of IC1b from reverse-connected batteries at the 9V test terminals, resulting in only 1/24th of the battery voltage appearing at IC1b's inverting input. Battery voltages in the range of 1-1.5V at the 1.5V test terminals will produce 0.25-0.375V at the inverting input of IC1a, while voltages in the range of 6-9V at the 9V test terminals will yield 0.25-0.375V at the inverting input of IC1b. Potentiometer VR1 is part of a voltage divider used to generate a comparison voltage that is variable within the same 0.25-0.375V range. This voltage is applied to the non-inverting inputs of both IC1a and IC1b. When the sampled battery voltage exceeds this comparison voltage, the respective comparator output swings low, activating Q3/Q4 to energize the pager motor. A 68Ω resistor in the collector circuit of Q4 ensures that higher battery voltages do not overdrive the motor. Testing an earlier version of this circuit with batteries exhibiting high internal impedance revealed that when VR1 was adjusted to the indicating point, the pager motor slowed rather than switched off due to a rebound in battery voltage at motor switch-off, which caused the circuit to immediately reactivate the motor. To mitigate this effect, a small amount of positive feedback is applied around the comparators when the motor is turned off. The feedback is disabled while the motor is operational to prevent affecting the indicating point of VR1. When the motor is running, Q5 conducts, and D5 is reverse-biased, ensuring the comparison voltage at the non-inverting inputs of the comparators remains unaffected. If the motor stops, Q5 switches off, and the 2.7MΩ resistor pulls the comparison voltage higher via D5, ensuring that any resulting battery voltage rebound does not restart the motor. Diode D7 prevents reverse breakdown of Q4 in the event of reverse battery connection at the 9V terminals. A similar diode is unnecessary in the 1.5V section of the circuit, as 1.5V is well below the reverse breakdown voltage of Q3. The prototype utilized "Magtrix" magnetic connectors on short flexible leads as the 1.5V test terminals, allowing connections for AAA, AA, C, and D cells while ensuring that they cannot be brought close enough to connect 9V types. However, magnetic connectors are unsuitable for the 9V test terminals due to some brands of 9V batteries having non-magnetic terminals. A conventional 9V battery snap can be employed instead. For accessibility, the knob on VR1 should be pointer-shaped (e.g., DSE P-7102) to facilitate tactile assessment of the degree of rotation.

The circuit design incorporates a variety of components to ensure reliability and safety during operation. The use of zener diodes for voltage regulation and protection diodes for reverse polarity safeguards the circuit from potential damage. The inclusion of a blocking oscillator allows for effective voltage boosting, ensuring accurate readings even with lower battery voltages. The feedback mechanism around the comparators enhances the stability of the motor operation, preventing unintended activation due to transient voltage changes. The careful consideration of component values, such as the resistors in the voltage divider networks, ensures that the circuit operates within safe thresholds for both blind and deaf-blind users, providing a practical solution for battery testing in a user-friendly manner. The design emphasizes accessibility, allowing for straightforward use by individuals with varying degrees of sight and hearing impairment.Many blind and deaf-blind people use portable electronic devices to assist their everyday lives but it is difficult for them to test the batteries used in that equipment. Talking voltmeters are available for the blind but there is no commercially available equivalent usable by deaf-blind persons.

This device enables blind, deaf-blind and sighted p eople to test batteries. It will test AAA, AA, C and D cells, as well as 9V "transistor" batteries. All rechargeable and non-rechargeable cell types are supported. The circuit needs no calibration. To use the tester, turn potentio-meter VR1 fully counter-clockwise and then connect the battery to be tested to the appropriate set of test terminals. If the battery has any usable charge, the pager motor in the tester will immediately vibrate. VR1 is then slowly rotated in a clockwise direction just far enough to stop the vibration. The position of VR1 then indicates the loaded voltage of the battery on a scale of 1-1. 5V (if the battery is connected to the 1. 5V test terminals) or 6-9V (if the battery is connected to the 9V test terminals). A regulated +5. 1V rail is generated from the battery under test with the aid of zener diode ZD1. For 9V tests, a 150O resistor limits the zener current, while diode D2 protects the circuit from reverse polarity battery connection.

For 1. 5V tests, a blocking oscillator formed by Q1, Q2 and L1 steps up the battery voltage before it is applied to the regulator. This configuration works reliably with inputs down to below 0. 9V. The output of the oscillator is rectified by D1 and smoothed by the 33 µF capacitor. The circuit has to survive reverse connection of the battery under test. This creates a problem, because the LM393 cannot withstand a voltage more negative than -0. 3V at its inputs. Diodes D1 and D2 indirectly protect the non-inverting inputs from negative voltages but series diodes cannot be used to protect the inverting inputs because of the unpredictable voltage drop they introduce.

The solution used is to shunt negative voltages at the 1. 5V test terminals with diode D3 in conjunction a 1kO resistor (R1). D3 limits the voltage at its cathode to about -0. 7V, while resistors R2-R4 divide this by three to give no less than -0. 23V at the inverting input (pin 2) of IC1a. When the battery is connected the right way around, D3 is reverse-biased and R1-R4 form a voltage divider that applies a quarter of the battery voltage to IC1a`s inverting input. Similarly, D4 and R5-R10 protect the inverting input (pin 6) of IC1b from reverse-connected batteries at the 9V test terminals.

However, in this case only 1/24th of the battery voltage appears at IC1b`s inverting input. Battery voltages in the range 1-1. 5V at the 1. 5V test terminals will therefore produce 0. 25-0. 375V at the inverting input of IC1a, while battery voltages in the range 6-9V at the 9V test terminals will produce 0. 25-0. 375V at the inverting input of IC1b. Potentiometer VR1 forms part of a voltage divider used to generate a comparison voltage that is variable over the same 0.

25-0. 375V range. This is applied to the non-inverting inputs of both IC1a and IC1b. When the sampled battery voltage exceeds this comparison voltage, the respective comparator output swings low, switching on Q3/Q4 to energise the pager motor. The 68O resistor in the collector circuit of Q4 ensures that higher battery voltages do not overdrive the motor.

When testing an earlier version of this circuit with batteries that have high internal impedance, it was found that when VR1 was advanced to the indicating point, the pager motor slowed down rather than switched off. This occurred due to a rebound in battery voltage at motor switch-off, which in turn caused the circuit to immediately switch the motor back on again.

To counteract this effect, a small amount of positive feedback is applied around the comparators when the motor switches off. The feedback is disabled while the motor is running so that the indicating point of VR1 is not affected.

This works as follows: when the motor is running, Q5 is conducting and D5 is reverse biased, so the comparison voltage at the non-inverting inputs of the comparators is not affected. If the motor stops running, Q5 switches off and the 2. 7MO resistor pulls the comparison voltage higher via D5 to ensure that the resulting battery voltage rebound does not restart the motor.

Finally, diode D7 prevents reverse breakdown of Q4 in case of reverse battery connection at the 9V terminals. There is no need for a similar diode in the 1. 5V part of the circuit because 1. 5V is well below the reverse breakdown voltage of Q3. The prototype used "Magtrix" magnetic connectors on short flexible leads as the 1. 5V test terminals. These allow the connection of AAA, AA, C and D cells but are arranged so that they cannot be brought closely together enough to connect 9V types.

Unfortunately, magnetic connectors cannot be used for the 9V test terminals because some brands of 9V batteries have non-magnetic terminals. A conventional 9V battery snap can be used instead. For blind people, the knob on VR1 should be pointer-shaped (eg, DSE P-7102) so that the degree of rotation can be easily assessed by touch.

🔗 External reference

The circuit design incorporates a variety of components to ensure reliability and safety during operation. The use of zener diodes for voltage regulation and protection diodes for reverse polarity safeguards the circuit from potential damage. The inclusion of a blocking oscillator allows for effective voltage boosting, ensuring accurate readings even with lower battery voltages. The feedback mechanism around the comparators enhances the stability of the motor operation, preventing unintended activation due to transient voltage changes. The careful consideration of component values, such as the resistors in the voltage divider networks, ensures that the circuit operates within safe thresholds for both blind and deaf-blind users, providing a practical solution for battery testing in a user-friendly manner. The design emphasizes accessibility, allowing for straightforward use by individuals with varying degrees of sight and hearing impairment.Many blind and deaf-blind people use portable electronic devices to assist their everyday lives but it is difficult for them to test the batteries used in that equipment. Talking voltmeters are available for the blind but there is no commercially available equivalent usable by deaf-blind persons.

This device enables blind, deaf-blind and sighted p eople to test batteries. It will test AAA, AA, C and D cells, as well as 9V "transistor" batteries. All rechargeable and non-rechargeable cell types are supported. The circuit needs no calibration. To use the tester, turn potentio-meter VR1 fully counter-clockwise and then connect the battery to be tested to the appropriate set of test terminals. If the battery has any usable charge, the pager motor in the tester will immediately vibrate. VR1 is then slowly rotated in a clockwise direction just far enough to stop the vibration. The position of VR1 then indicates the loaded voltage of the battery on a scale of 1-1. 5V (if the battery is connected to the 1. 5V test terminals) or 6-9V (if the battery is connected to the 9V test terminals). A regulated +5. 1V rail is generated from the battery under test with the aid of zener diode ZD1. For 9V tests, a 150O resistor limits the zener current, while diode D2 protects the circuit from reverse polarity battery connection.

For 1. 5V tests, a blocking oscillator formed by Q1, Q2 and L1 steps up the battery voltage before it is applied to the regulator. This configuration works reliably with inputs down to below 0. 9V. The output of the oscillator is rectified by D1 and smoothed by the 33 µF capacitor. The circuit has to survive reverse connection of the battery under test. This creates a problem, because the LM393 cannot withstand a voltage more negative than -0. 3V at its inputs. Diodes D1 and D2 indirectly protect the non-inverting inputs from negative voltages but series diodes cannot be used to protect the inverting inputs because of the unpredictable voltage drop they introduce.

The solution used is to shunt negative voltages at the 1. 5V test terminals with diode D3 in conjunction a 1kO resistor (R1). D3 limits the voltage at its cathode to about -0. 7V, while resistors R2-R4 divide this by three to give no less than -0. 23V at the inverting input (pin 2) of IC1a. When the battery is connected the right way around, D3 is reverse-biased and R1-R4 form a voltage divider that applies a quarter of the battery voltage to IC1a`s inverting input. Similarly, D4 and R5-R10 protect the inverting input (pin 6) of IC1b from reverse-connected batteries at the 9V test terminals.

However, in this case only 1/24th of the battery voltage appears at IC1b`s inverting input. Battery voltages in the range 1-1. 5V at the 1. 5V test terminals will therefore produce 0. 25-0. 375V at the inverting input of IC1a, while battery voltages in the range 6-9V at the 9V test terminals will produce 0. 25-0. 375V at the inverting input of IC1b. Potentiometer VR1 forms part of a voltage divider used to generate a comparison voltage that is variable over the same 0.

25-0. 375V range. This is applied to the non-inverting inputs of both IC1a and IC1b. When the sampled battery voltage exceeds this comparison voltage, the respective comparator output swings low, switching on Q3/Q4 to energise the pager motor. The 68O resistor in the collector circuit of Q4 ensures that higher battery voltages do not overdrive the motor.

When testing an earlier version of this circuit with batteries that have high internal impedance, it was found that when VR1 was advanced to the indicating point, the pager motor slowed down rather than switched off. This occurred due to a rebound in battery voltage at motor switch-off, which in turn caused the circuit to immediately switch the motor back on again.

To counteract this effect, a small amount of positive feedback is applied around the comparators when the motor switches off. The feedback is disabled while the motor is running so that the indicating point of VR1 is not affected.

This works as follows: when the motor is running, Q5 is conducting and D5 is reverse biased, so the comparison voltage at the non-inverting inputs of the comparators is not affected. If the motor stops running, Q5 switches off and the 2. 7MO resistor pulls the comparison voltage higher via D5 to ensure that the resulting battery voltage rebound does not restart the motor.

Finally, diode D7 prevents reverse breakdown of Q4 in case of reverse battery connection at the 9V terminals. There is no need for a similar diode in the 1. 5V part of the circuit because 1. 5V is well below the reverse breakdown voltage of Q3. The prototype used "Magtrix" magnetic connectors on short flexible leads as the 1. 5V test terminals. These allow the connection of AAA, AA, C and D cells but are arranged so that they cannot be brought closely together enough to connect 9V types.

Unfortunately, magnetic connectors cannot be used for the 9V test terminals because some brands of 9V batteries have non-magnetic terminals. A conventional 9V battery snap can be used instead. For blind people, the knob on VR1 should be pointer-shaped (eg, DSE P-7102) so that the degree of rotation can be easily assessed by touch.

🔗 External reference