Automotive charger for ni-cad battery packs

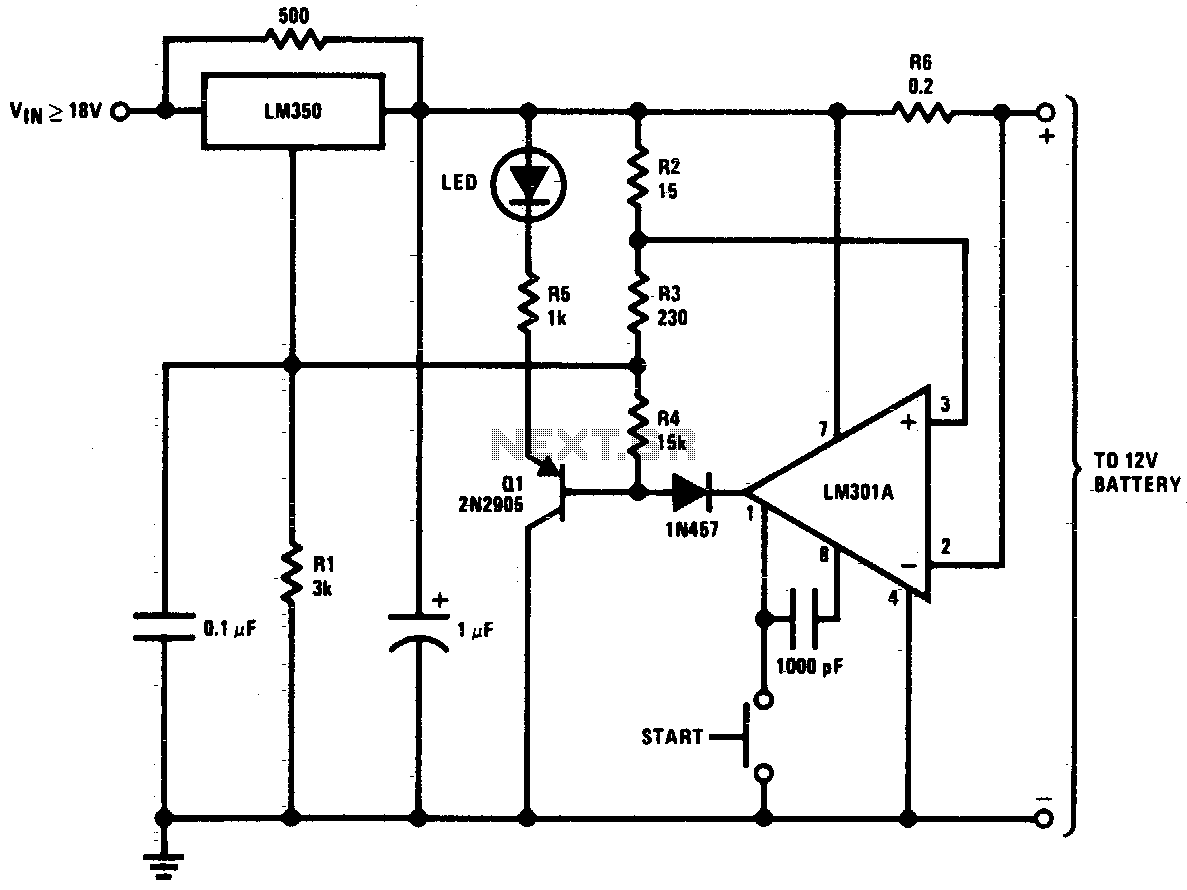

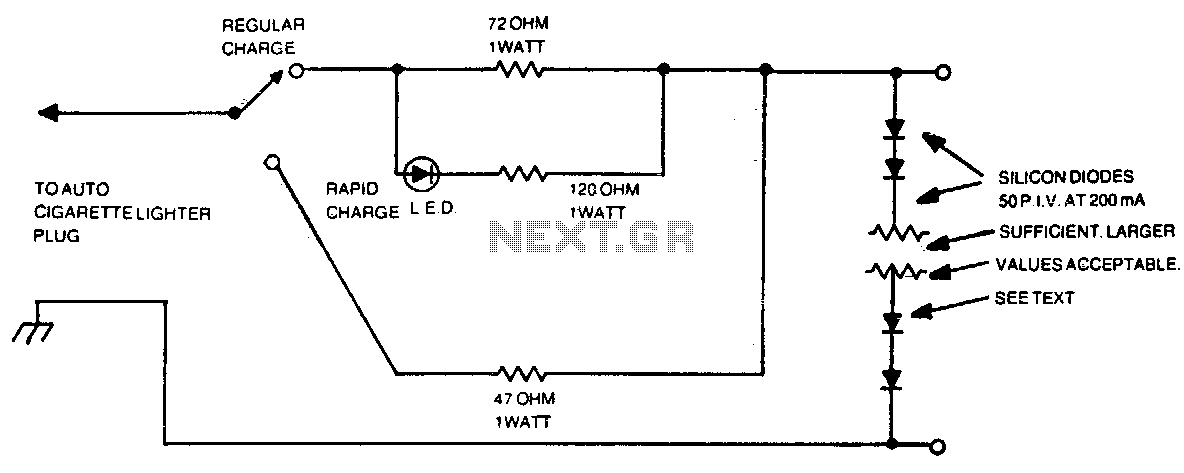

The number of silicon diodes across the output is determined by the voltage of the battery pack. Each diode is considered at 0 volts. For example, a 10-volt pack would require 10/0 = 157, or 16 diodes.

In the context of a circuit design utilizing silicon diodes, it is essential to understand the relationship between the battery pack voltage and the required number of diodes to achieve desired electrical characteristics. Silicon diodes are semiconductor devices that allow current to flow in one direction while blocking it in the opposite direction, thereby serving as rectifiers or protection devices in various applications.

When determining the number of diodes needed, one must consider the total forward voltage drop across the diodes in series. The forward voltage drop of a typical silicon diode is approximately 0.7 volts. Therefore, to calculate the number of diodes required for a specific battery pack voltage, the following formula is applied:

Number of diodes = Battery voltage / Forward voltage drop per diode.

For instance, if the battery pack voltage is 10 volts, the calculation would be:

Number of diodes = 10 volts / 0.7 volts per diode ≈ 14.3.

Since the number of diodes must be a whole number, rounding up would yield the requirement for 15 diodes to ensure that the voltage drop does not exceed the battery voltage.

This arrangement is critical in applications where voltage regulation and protection against reverse polarity are necessary. The diodes must be rated for the expected current and voltage levels, ensuring that they can handle the load without failure. It is also advisable to include heat sinks or other cooling methods if the diodes are expected to operate at higher currents to prevent thermal damage.

In summary, careful consideration of the diode specifications and the overall circuit design is essential to ensure reliable operation and efficiency in the intended application.The number of silicon diodes across the output is determined by the voltage of the battery pack. Figure each diode at 0 volt For example, a 10- volt pack would require 10/0 = 157, or 16 diodes.

In the context of a circuit design utilizing silicon diodes, it is essential to understand the relationship between the battery pack voltage and the required number of diodes to achieve desired electrical characteristics. Silicon diodes are semiconductor devices that allow current to flow in one direction while blocking it in the opposite direction, thereby serving as rectifiers or protection devices in various applications.

When determining the number of diodes needed, one must consider the total forward voltage drop across the diodes in series. The forward voltage drop of a typical silicon diode is approximately 0.7 volts. Therefore, to calculate the number of diodes required for a specific battery pack voltage, the following formula is applied:

Number of diodes = Battery voltage / Forward voltage drop per diode.

For instance, if the battery pack voltage is 10 volts, the calculation would be:

Number of diodes = 10 volts / 0.7 volts per diode ≈ 14.3.

Since the number of diodes must be a whole number, rounding up would yield the requirement for 15 diodes to ensure that the voltage drop does not exceed the battery voltage.

This arrangement is critical in applications where voltage regulation and protection against reverse polarity are necessary. The diodes must be rated for the expected current and voltage levels, ensuring that they can handle the load without failure. It is also advisable to include heat sinks or other cooling methods if the diodes are expected to operate at higher currents to prevent thermal damage.

In summary, careful consideration of the diode specifications and the overall circuit design is essential to ensure reliable operation and efficiency in the intended application.The number of silicon diodes across the output is determined by the voltage of the battery pack. Figure each diode at 0 volt For example, a 10- volt pack would require 10/0 = 157, or 16 diodes.