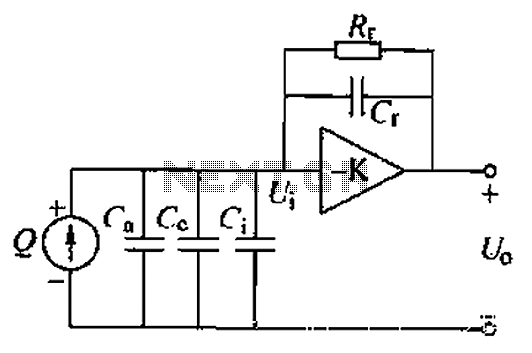

Instrumentation circuit

The mechanical chassis prototype, as illustrated in the accompanying image, was constructed using two materials: foam and aluminum. Foam was selected for its ease of manipulation, while aluminum was chosen for its excellent strength-to-weight ratio. The prototype features a rotary mechanism consisting of a central metal axle connected to the cuvette holder cylinder, which can be driven in steps by a DC electric motor and appropriate control code.

The mechanical chassis serves as a foundational structure for various applications, particularly in laboratory settings where precise movement is required. The use of foam in the design allows for lightweight construction, facilitating portability and ease of handling. The aluminum components contribute to the overall durability and structural integrity of the prototype, ensuring it can withstand the operational stresses encountered during use.

The rotary mechanism is a critical feature of the prototype, enabling controlled rotation of the cuvette holder. This is achieved through the integration of a DC electric motor, which provides the necessary torque for movement. The motor can be controlled using a microcontroller or programmable logic device, which executes a predefined code to manage the stepper motion. This setup allows for precise positioning and consistent repeatability, essential for experiments requiring accurate sample placement.

The choice of materials and the design of the rotary mechanism exemplify a balance between functionality and efficiency. The prototype can be further enhanced by incorporating sensors for feedback control, allowing for real-time adjustments to the motor's operation based on the position of the cuvette holder. Such enhancements would improve the accuracy and reliability of the system, making it suitable for more demanding applications in research and development environments.The mechanical chassis prototype, as can be seen from the image on the left, was made using two materials: foam and aluminium. Foam was chosen due to its easy manipulation and aluminium due to its excellent strength to weight ratio.

The prototype includes a rotary mechanism (a central metal axon connected to the cuvette holder cylinder), which can be driven in steps by a DC electric motor (and a suitable code). 🔗 External reference

The mechanical chassis serves as a foundational structure for various applications, particularly in laboratory settings where precise movement is required. The use of foam in the design allows for lightweight construction, facilitating portability and ease of handling. The aluminum components contribute to the overall durability and structural integrity of the prototype, ensuring it can withstand the operational stresses encountered during use.

The rotary mechanism is a critical feature of the prototype, enabling controlled rotation of the cuvette holder. This is achieved through the integration of a DC electric motor, which provides the necessary torque for movement. The motor can be controlled using a microcontroller or programmable logic device, which executes a predefined code to manage the stepper motion. This setup allows for precise positioning and consistent repeatability, essential for experiments requiring accurate sample placement.

The choice of materials and the design of the rotary mechanism exemplify a balance between functionality and efficiency. The prototype can be further enhanced by incorporating sensors for feedback control, allowing for real-time adjustments to the motor's operation based on the position of the cuvette holder. Such enhancements would improve the accuracy and reliability of the system, making it suitable for more demanding applications in research and development environments.The mechanical chassis prototype, as can be seen from the image on the left, was made using two materials: foam and aluminium. Foam was chosen due to its easy manipulation and aluminium due to its excellent strength to weight ratio.

The prototype includes a rotary mechanism (a central metal axon connected to the cuvette holder cylinder), which can be driven in steps by a DC electric motor (and a suitable code). 🔗 External reference