ir remote extender circuit

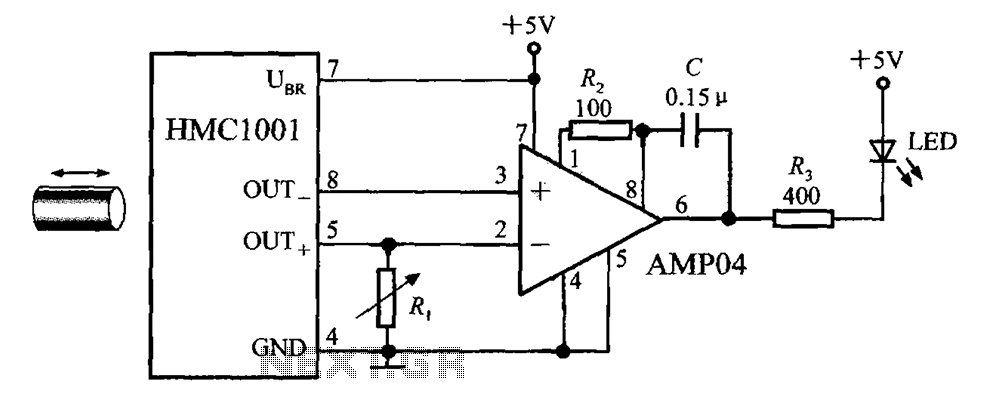

This infrared (IR) remote extender enhances the range of most basic IR remotes operating at a 40KHz modulation frequency significantly. When in operation, the remote is aimed at the detector on the circuit, and a button is pressed. The Sharp IR detector decodes the 40KHz modulated signal into a series of pulses that activate a 555 timer. The 555 timer outputs these pulses, which are then re-modulated to drive an IR LED. This circuit is particularly effective in large spaces, such as presentation halls, where standard IR remotes may have limited range. By extending the wires to the output LED using shielded cable, control of devices that do not have a direct line of sight can be achieved, such as televisions located behind a wall in a separate room. Only the CMOS TLC555 timer is suitable for this circuit, as the original NE555 timer does not operate reliably at 40KHz. Acceptable alternatives are listed in the parts inventory. To calibrate the circuit, a frequency counter should be connected in parallel with D1 while grounding the base of Q1. R3 should be adjusted until the counter reads 40KHz. In the absence of a counter, the calibration can be performed by aiming a remote at the circuit, pressing a button, and adjusting R3 until functionality is achieved. This process may require several attempts, as not all remotes transmit signals continuously.

The IR remote extender circuit utilizes a Sharp IR detector to receive signals from a standard IR remote control. The received 40KHz modulated signal is processed and converted into a series of electrical pulses. These pulses are fed into a CMOS TLC555 timer configured in monostable mode, which generates output pulses at the same frequency as the input signal. The output from the 555 timer is then used to drive an IR LED, which emits IR light that can be detected by the intended device, such as a television or audio system.

To ensure reliable operation, the circuit design incorporates a few key components: the Sharp IR detector, the TLC555 timer, and the IR LED. The use of shielded cable for extending the output LED is essential to minimize interference and maintain signal integrity over longer distances. The calibration process is crucial, as it ensures that the circuit operates at the correct frequency, allowing for optimal performance of the IR remote extender.

The configuration of the circuit should include appropriate power supply decoupling to prevent voltage fluctuations from affecting the performance of the timer and the IR detector. Additionally, the design may include filtering capacitors to smooth out any noise in the power supply line. The selection of the IR LED must also consider its wavelength and intensity to ensure compatibility with the devices being controlled.

In summary, this IR remote extender circuit provides a practical solution for extending the operational range of standard IR remotes in environments where direct line-of-sight is obstructed. Proper calibration and component selection are essential for achieving the desired performance and reliability.This IR remote extender can increase the range of most simple IR remotes (those operating on a 40KHz modulation) a significant distance. In use, the remote is pointed toward the detector on the circuit, and a button is pressed. The Sharp IR detector then decodes the 40KHz modulated signal into a series of pulses, which trigger a 555 timer.

The 555 outputs pulses which are re-modulated and used to drive an IR LED. The circuit is excellent for use in a large room like a presentation hall where a typical IR remote is a bit weak. By extending the wires to the output LED (using shielded cable) you can control a device where line of sight isn`t available (such as a wall full of TVs in another room).

Only the CMOS TLC555 timer can be used in this circuit. The original NE555 cannot operate reliably at 40KHz. Acceptable substitutions are shown in the parts list. To calibrate the circuit, use a frequency counter. Connect it in parallel with D1 and then ground the base of Q1. Adjust R3 for 40KHz on the counter. If a counter is not available, you will just have to point a remote at the circuit, press a button, and then adjust R3 until it works. This can take a few tries as not all remotes transmit continuously. 🔗 External reference

The IR remote extender circuit utilizes a Sharp IR detector to receive signals from a standard IR remote control. The received 40KHz modulated signal is processed and converted into a series of electrical pulses. These pulses are fed into a CMOS TLC555 timer configured in monostable mode, which generates output pulses at the same frequency as the input signal. The output from the 555 timer is then used to drive an IR LED, which emits IR light that can be detected by the intended device, such as a television or audio system.

To ensure reliable operation, the circuit design incorporates a few key components: the Sharp IR detector, the TLC555 timer, and the IR LED. The use of shielded cable for extending the output LED is essential to minimize interference and maintain signal integrity over longer distances. The calibration process is crucial, as it ensures that the circuit operates at the correct frequency, allowing for optimal performance of the IR remote extender.

The configuration of the circuit should include appropriate power supply decoupling to prevent voltage fluctuations from affecting the performance of the timer and the IR detector. Additionally, the design may include filtering capacitors to smooth out any noise in the power supply line. The selection of the IR LED must also consider its wavelength and intensity to ensure compatibility with the devices being controlled.

In summary, this IR remote extender circuit provides a practical solution for extending the operational range of standard IR remotes in environments where direct line-of-sight is obstructed. Proper calibration and component selection are essential for achieving the desired performance and reliability.This IR remote extender can increase the range of most simple IR remotes (those operating on a 40KHz modulation) a significant distance. In use, the remote is pointed toward the detector on the circuit, and a button is pressed. The Sharp IR detector then decodes the 40KHz modulated signal into a series of pulses, which trigger a 555 timer.

The 555 outputs pulses which are re-modulated and used to drive an IR LED. The circuit is excellent for use in a large room like a presentation hall where a typical IR remote is a bit weak. By extending the wires to the output LED (using shielded cable) you can control a device where line of sight isn`t available (such as a wall full of TVs in another room).

Only the CMOS TLC555 timer can be used in this circuit. The original NE555 cannot operate reliably at 40KHz. Acceptable substitutions are shown in the parts list. To calibrate the circuit, use a frequency counter. Connect it in parallel with D1 and then ground the base of Q1. Adjust R3 for 40KHz on the counter. If a counter is not available, you will just have to point a remote at the circuit, press a button, and then adjust R3 until it works. This can take a few tries as not all remotes transmit continuously. 🔗 External reference