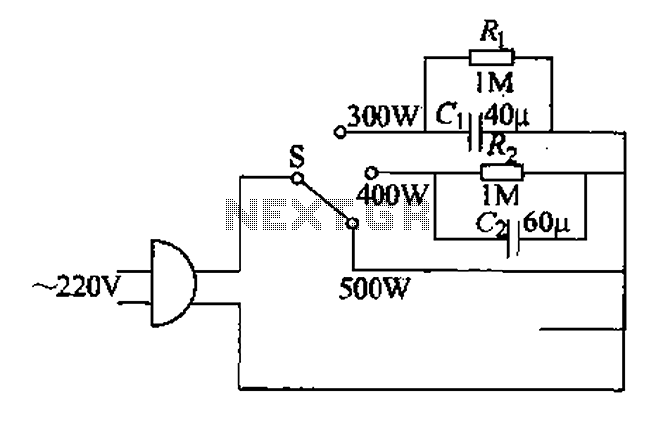

Irons circuit

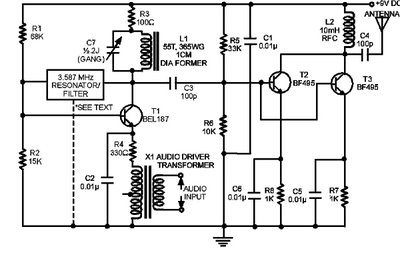

Each family has essential small appliances. The sub-type is an electric power jet, mainly used for clothes and hot shaping. The iron's circuit is shown in Figure 1-30. When using an iron, there is always a concern about using a 500W iron due to the excessive heat that can scorch fabric, which can be adjusted to 400W or 300W as shown in Figure 1-30XZ. The circuit utilizes a capacitor step-down approach to reduce the power consumed by the iron's heating wire. For the 400W and 300W electric irons, the required bulk capacitors are 60 µF and 40 µF, respectively. The capacitor voltage rating should exceed 400V. While paper dielectric capacitors are recommended, electrolytic capacitors should not be used. If a suitable capacitor is not available, multiple capacitors can be connected in tandem. A resistor for discharge is also necessary.

The described electric iron circuit employs a capacitor-based step-down transformer approach to manage power consumption effectively. In this design, the primary function of the capacitors is to limit the current flowing to the heating element, allowing for variable power settings. The use of a 60 µF capacitor for 400W and a 40 µF capacitor for 300W ensures that the heating element operates within safe limits, preventing overheating that could damage fabrics.

The circuit design must ensure that the voltage rating of the capacitors is adequate to handle the operational voltage, which should be rated for at least 400V. This precaution is crucial as it prevents capacitor failure, which could lead to circuit malfunction or safety hazards. Paper dielectric capacitors are preferred due to their stability and reliability under high voltage conditions, whereas electrolytic capacitors are not suitable for this application due to their lower voltage tolerance and potential for leakage.

In scenarios where specific capacitance values are unavailable, multiple capacitors can be connected in series or parallel configurations to achieve the desired capacitance while ensuring that the voltage rating remains sufficient. Additionally, a discharge resistor is essential to safely dissipate stored energy when the iron is turned off, preventing shock hazards during maintenance or handling.

Overall, this circuit design exemplifies a practical approach to controlling the temperature of an electric iron, making it safer and more efficient for everyday use. Proper attention to component selection and configuration is critical to achieving optimal performance and safety in household applications.Each family essential small appliances. Sub-type and electric power jet, mainly used for clothes and shake hot shaping. Irons circuit shown in Figure 1-30. When we use iron, ir oning, always afraid of using 500w iron due to excessive heat scorch cloth, it can be turned into iron 500w 400W or 300W make use As shown 1-30XZ can achieve this. Circuit capacitor step-down approach to reduce the power consumed by iron heating wire. Calculated at 400W and 300W electric iron bulk capacitors are 60t.rF and 40yF. Capacitor voltage should buck in 400V or more, the optional paper dielectric capacitors, electrolytic capacitors but can not be used.

No suitable capacity of the capacitor, the capacitor and a few available, used in tandem. ruler. Yes and discharge resistor.

The described electric iron circuit employs a capacitor-based step-down transformer approach to manage power consumption effectively. In this design, the primary function of the capacitors is to limit the current flowing to the heating element, allowing for variable power settings. The use of a 60 µF capacitor for 400W and a 40 µF capacitor for 300W ensures that the heating element operates within safe limits, preventing overheating that could damage fabrics.

The circuit design must ensure that the voltage rating of the capacitors is adequate to handle the operational voltage, which should be rated for at least 400V. This precaution is crucial as it prevents capacitor failure, which could lead to circuit malfunction or safety hazards. Paper dielectric capacitors are preferred due to their stability and reliability under high voltage conditions, whereas electrolytic capacitors are not suitable for this application due to their lower voltage tolerance and potential for leakage.

In scenarios where specific capacitance values are unavailable, multiple capacitors can be connected in series or parallel configurations to achieve the desired capacitance while ensuring that the voltage rating remains sufficient. Additionally, a discharge resistor is essential to safely dissipate stored energy when the iron is turned off, preventing shock hazards during maintenance or handling.

Overall, this circuit design exemplifies a practical approach to controlling the temperature of an electric iron, making it safer and more efficient for everyday use. Proper attention to component selection and configuration is critical to achieving optimal performance and safety in household applications.Each family essential small appliances. Sub-type and electric power jet, mainly used for clothes and shake hot shaping. Irons circuit shown in Figure 1-30. When we use iron, ir oning, always afraid of using 500w iron due to excessive heat scorch cloth, it can be turned into iron 500w 400W or 300W make use As shown 1-30XZ can achieve this. Circuit capacitor step-down approach to reduce the power consumed by iron heating wire. Calculated at 400W and 300W electric iron bulk capacitors are 60t.rF and 40yF. Capacitor voltage should buck in 400V or more, the optional paper dielectric capacitors, electrolytic capacitors but can not be used.

No suitable capacity of the capacitor, the capacitor and a few available, used in tandem. ruler. Yes and discharge resistor.